|

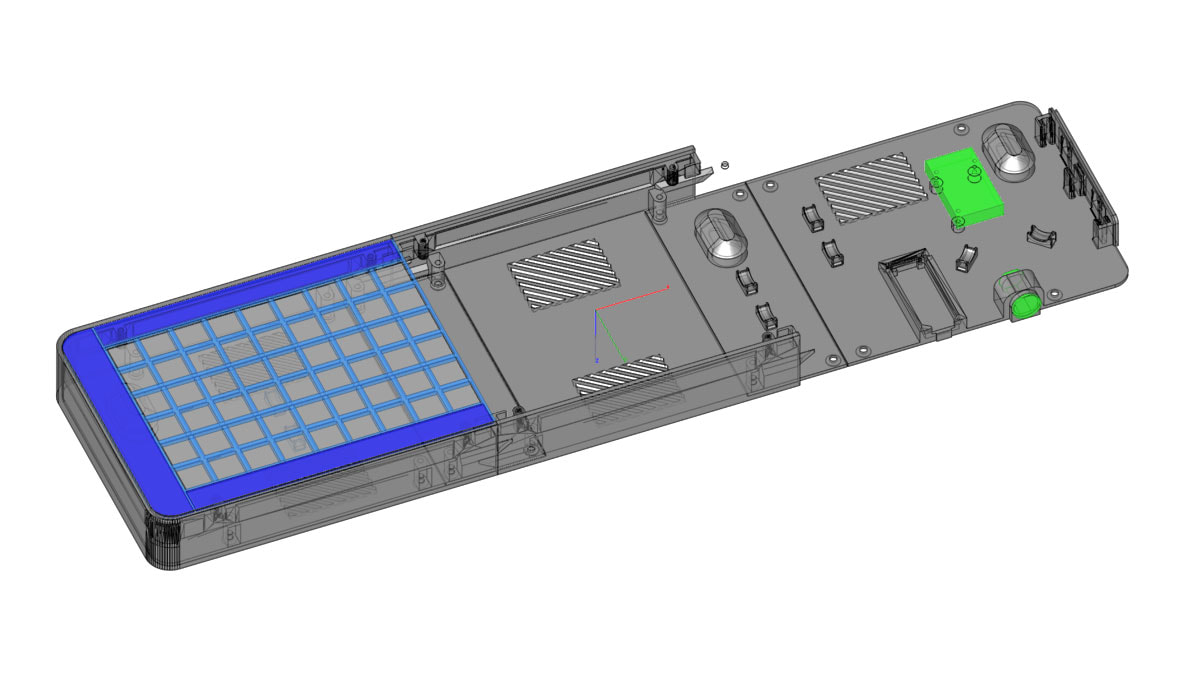

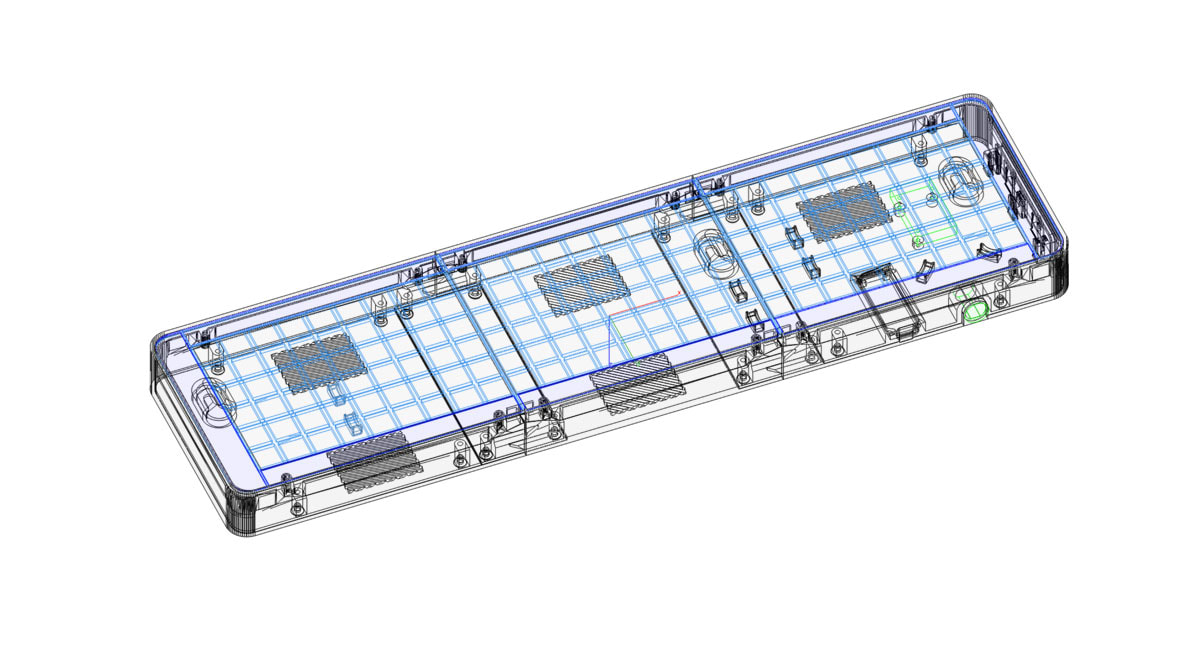

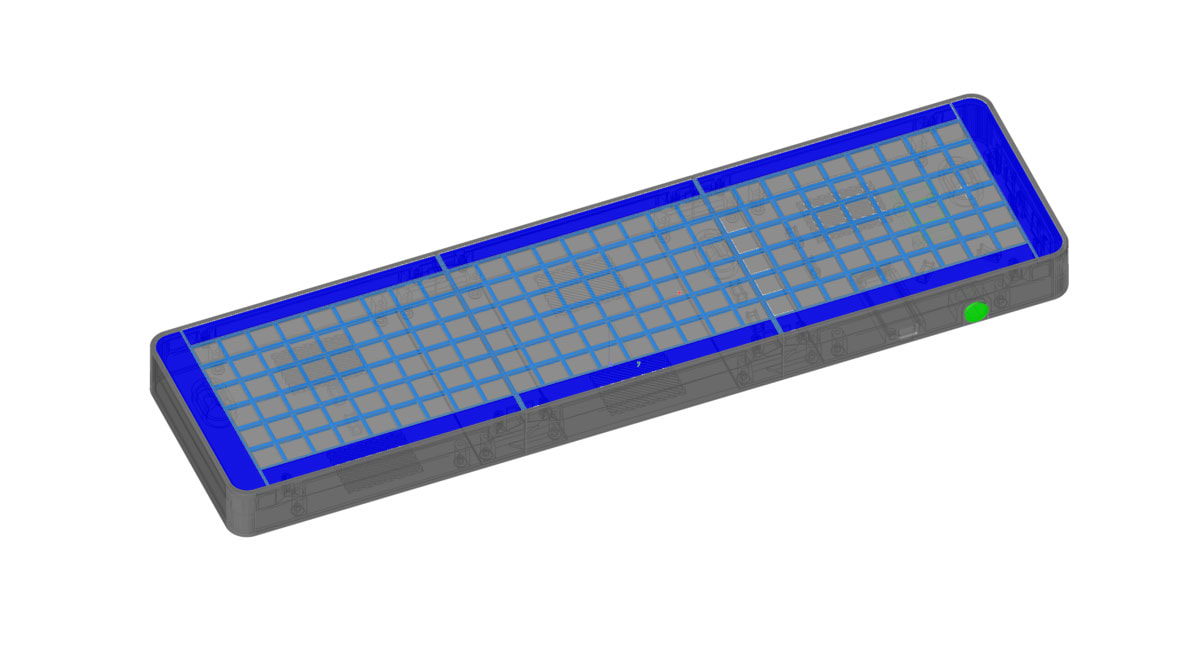

I think it is a sickness, there is nothing wrong with the Grid Clock V2 by Parallyze at thingivsere which I fully printed. Well mine did not look perfect due to several issues which I am working on, but it was functional and should have been fine. For some reason though I thought maybe I could just add this or that and when I was done it was completely remixed, and more complicated than it was originally. Will see how this goes, and if it does seem to work, I will post it up at Thingiverse.

0 Comments

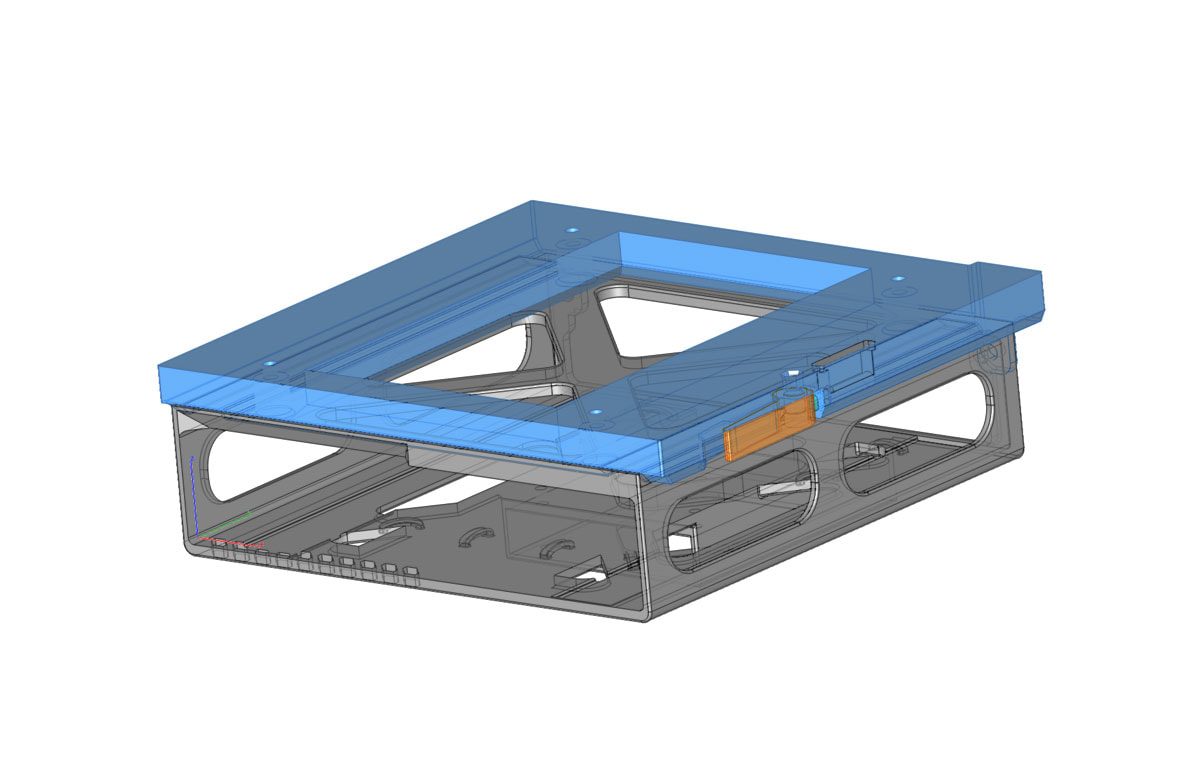

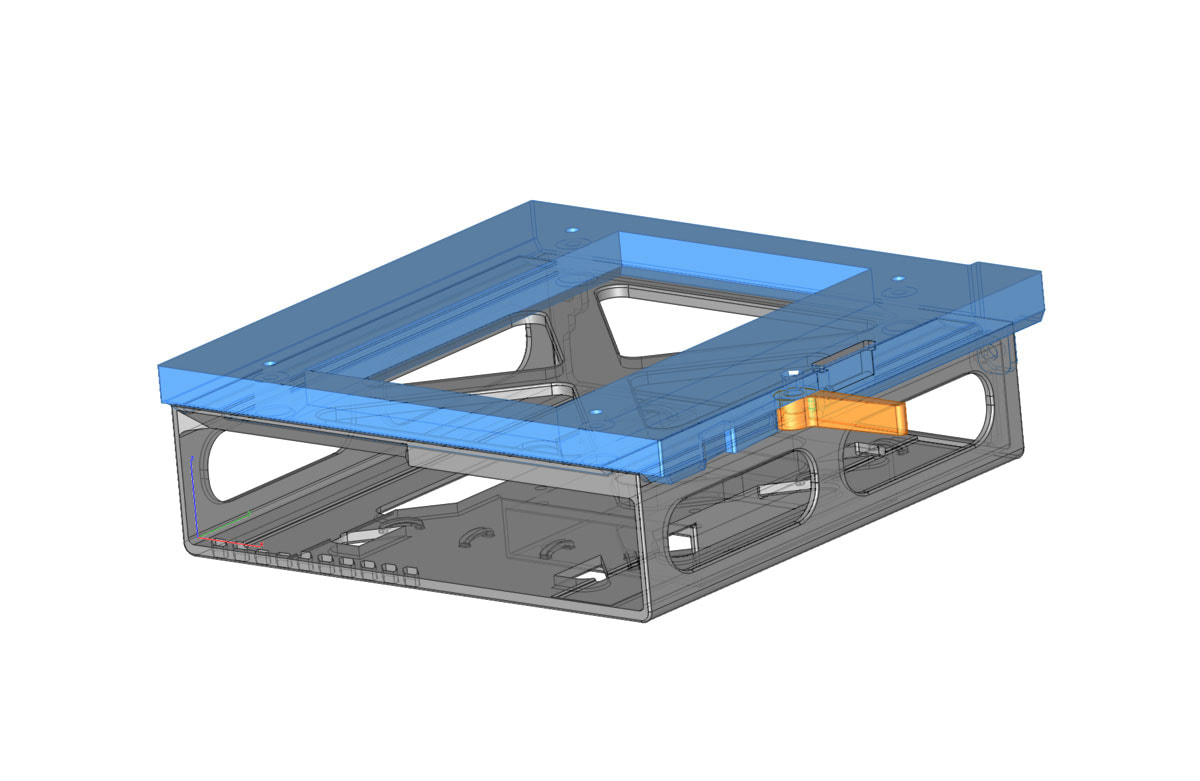

This is a newer design of the Under Desk Slide Out Mount For A Lenovo M700 (or M93p) Tiny PC which I previously uploaded to thingiverse. I have been using this mount and the only drawback is that there is no latch on the mount. This design seeks to fix that, however I don't have any plans right now to print and test it (too many other projects that need to get printed). I may upload it as a remix (work in progress however) but with the caveat that it is untested.

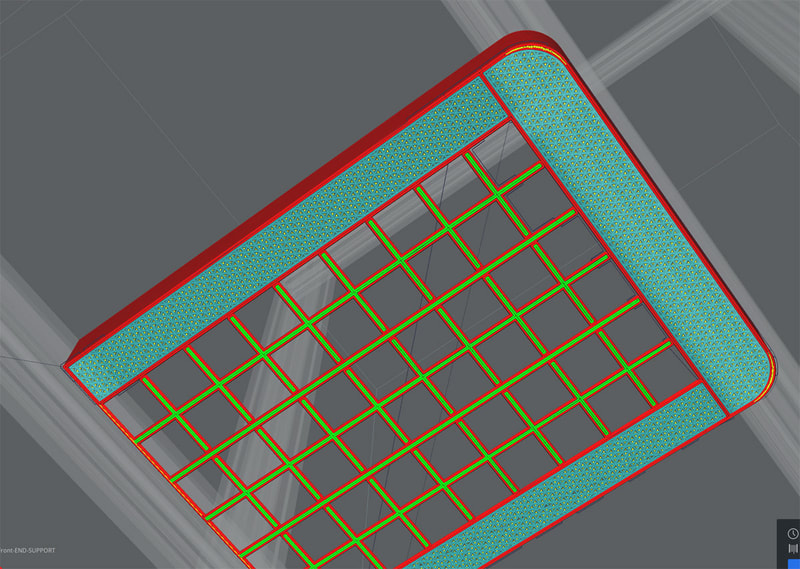

It requires a spring from a ball point clicky type pen, one M3x12mm cap head screw, an M3 locknut and a couple M4 washers (in addition to all the hardware listed in the linked model). It is posted here (but again it is not tested). UPDATE 8-20-2021: I updated the latch after using the same design on a Pi4 holder (posted here: https://www.thingiverse.com/thing:4936218). I have not tested this model, but I did test the latch using the Pi4 holder and it worked there. I'm not planning to print this however, since I already have the non-latching version of this thing, which works OK for me. If you do print this please provide feedback. I suggested calibrating flow prior to printing this since there are dovetails and close fitting parts. I needed a clock and found the Grid Clock V2 by Parallyze at thingivsere which looks perfect. This is one of those designs where it is clear that a lot of effort went into making it not only look great, but also work great. I wish I had half the talent to design and document things like this. He also provided some time saving tips on print settings which I used and can confirm really make a big difference. After printing a few parts, I did notice a few things I wanted to modify when I print my clock though. So I am printing a very slightly modified version of his design in the XL size, and plan to upload a remix when it's done. The only changes are to square off the ends of each section so they can be glued together (since I wanted it to be almost seamless) and also to add some inserts to the front to allow some cool design patterns to be inlaid (which are really just blocks printed as support). I got that idea after looking closely at the pics on the original and noticing that he printed the first layers with some wide gaps between lines which gives the front a grill like appearance, which I really like. I could not figure out how to do that in Cura however, so I instead designed some inlays which can be printed as supports and will give a similar look.

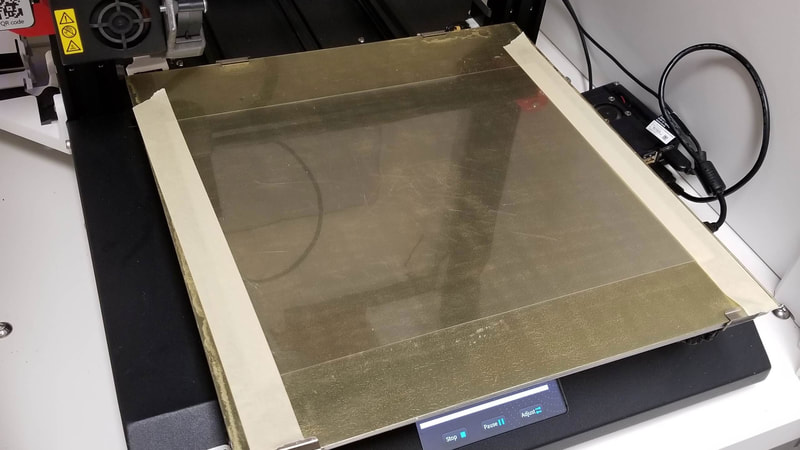

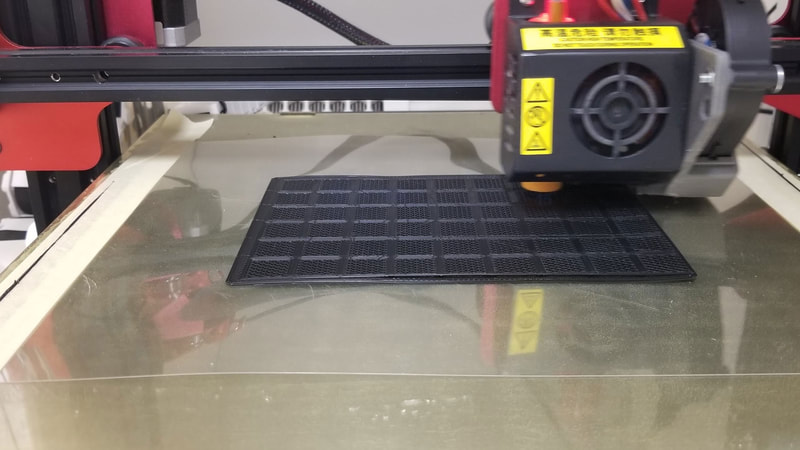

The remix will not be a simple print though, since it requires a good deal of knowledge of Cura, but I hope to be able to make something of a guide to help people with the settings. Additionally, I really liked onecton's "make" of the clock where he said he used a layer of PLA printed in black as the diffuser, along with a piece of paper. I'm working on something similar, but want to carry though the pattern from the front to the diffuser as well and have printed a few diffusers which I hope will work without adding paper behind them. In the process, I also found that I can print PLA on laser printer transparency film, which worked well but can imprint from the printed item so it will only be a rarely used trick I think. The diffusers are really a combination of 3 parts merged together, the first is a frame, then a 0.1mm thick solid layer, and above that a 0.2mm layer printed as support which provided a pattern. Everything was then printed at 0.1mm resolution and I used the Cura Z-offset plugin to increase the z-offset by the thickness of the transparency film which was taped to the bed (0.2mm thick). Then I printed as normal with a bed temp of 50°C and the print did start to lift, but being really thin it will not matter once it is sandwiched between the other parts of the clock. Although unprecedented, what happened today is hardly surprising. If there is room for surprise it is the limp planning and response to it. It defies logic that the Capital could be left so vulnerable at a time when all eyes of the nation, and much of the world, were on it. I'm sure due to the historical nature of the defilement of the seat of our government, and the successful disruption of the transfer of power (at best) or an actual coup attempt (at worst), some of the truth may come out in time. But I'm not holding my breath for the full story. What matters now is that, when it comes to Trump, the worst is yet to come.

I recently rebuilt my hot end on the Ender3 after the meltdown which left it globbed up with plastic. The globbing up was not the problem why I had to rebuild it though, but probably the start of why I had to clean it. The heater failed (suspected a weakend wire, and when I went to swap it, I found that the heatbreak was stuck. I could have burned it out, but I had spares so I just rebuilt everything so now it is nice and new, ready to get blobbed up again. However I found that I needed some thermal compound between the heatbreak and the heatsink. I did some research and found that most of the products used for computer CPU thermal grease are not able to sustain temps that a 3D printer hot end will commonly go to. One product that can, and then some is Boron Nitride. I found different companies selling it for different prices, and it several I found indicate that they are made by ZYP Coatings which is based in Oak Ridge, TN (which is also home to Oak Ridge National Laboratory). No idea if there is a reason for that, but chances are there are a lot of smart people in that town, so I would not be surprised if there is some connection. In any case, the Boron Nitride thermal grease looks promising and the cheapest place I could find it was at filamentone.com (no affiliation) and their shipping via USPS was cheap too. The stuff comes in a small metal tube (like a small toothpaste tube), and not the syringe looking dispenser they show on the site. I just installed the heatbreak with the boron nitride paste, and will see how it goes (and will update here if there are issues with heat creep).

The stuff seems relatively safe, but there are some considerations since it is a eye and lung irritant (MSDS here). As a side note, it is nice that they have an MSDS for the stuff, considering most thermal compounds from China that I found on Amazon or Ebay don't even mention one (we could probably learn something about deregulation from China ;-). To be on the safe side, I took the printer outside for the first heatup cycle after installation, and ran a PID tune outside as well, since it was mentioned that "Initial exposure to high temperatures evolves, in small amounts, fumes that may be irritating or corrosive to the upper respiratory system." Though I suspect that "high temperatures" for this stuff is really a lot more than anything my printer is capable of - like 600°C probably. At 240°C which I started it up at, I'd guess it may have boiled off some water since it is 65-70% water. The dust is however an irritant so when swapping the heatbreak or removing it from the heatsink, I would probably wear a face mask or respirator to avoid any dust. Update 9/23/2021: I was gonna use the Boron Nitride again to rebuild a hot end, and found it was all dried out. It's not super surprising but still disappointing that it did not last in storage. For the record, it was capped tightly in a bag. I don't think for a single use it is worth buying this stuff, and will stick to using the small one time use packets for my printers. |

Stoopid MeWelcome to my Stoopid corner of teh Internet. It's mostly gonna be 3D printing stuff, but I also post some recipes, projects, and the occasional rant here as well. More Stoopid stuff is updated regularly. Archives

July 2024

Categories |

RSS Feed

RSS Feed