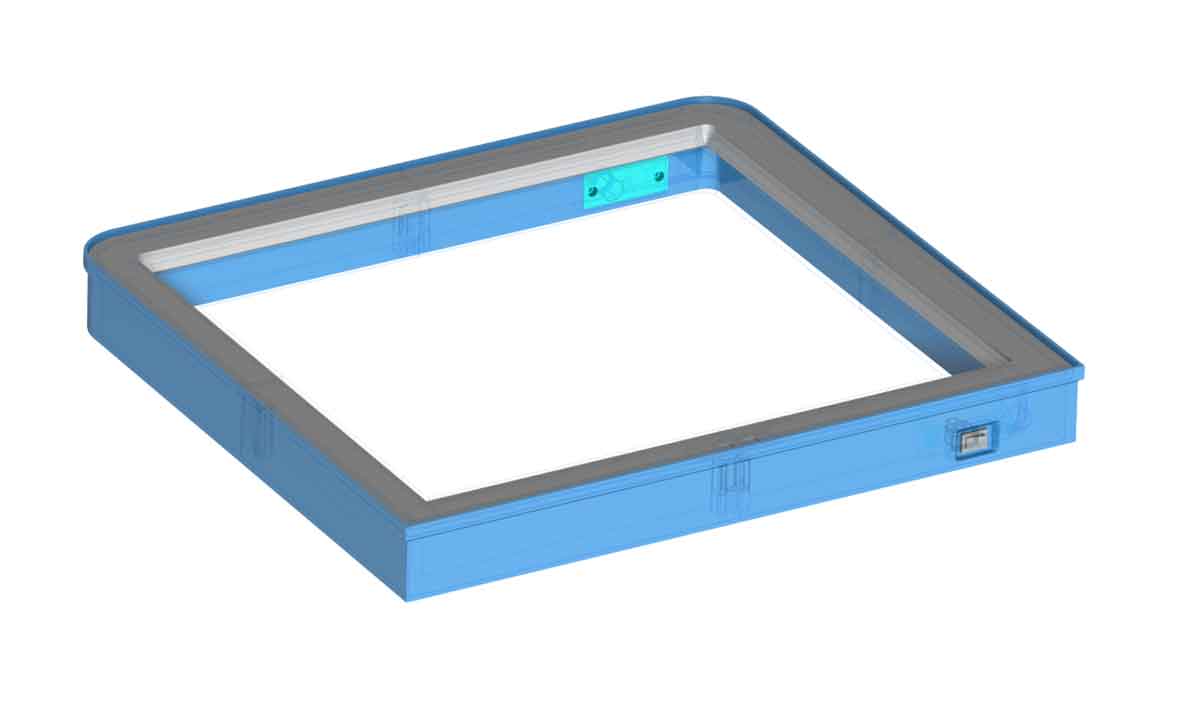

Update 10/28/2023: I think the design for the DK Riser Remix is completed, and am now printing the prototype. Even though this remix will be a very bare bones riser (without any vents), compared to the original, I decided to spice it up a bit with a few extra features, including the following:

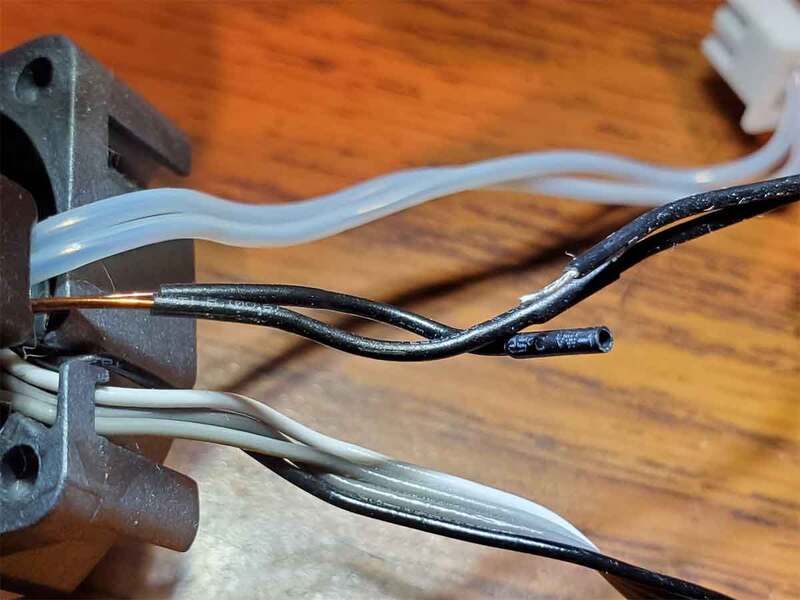

- A switch on the front, with a wire channel and covers, so there is no exposed wiring.

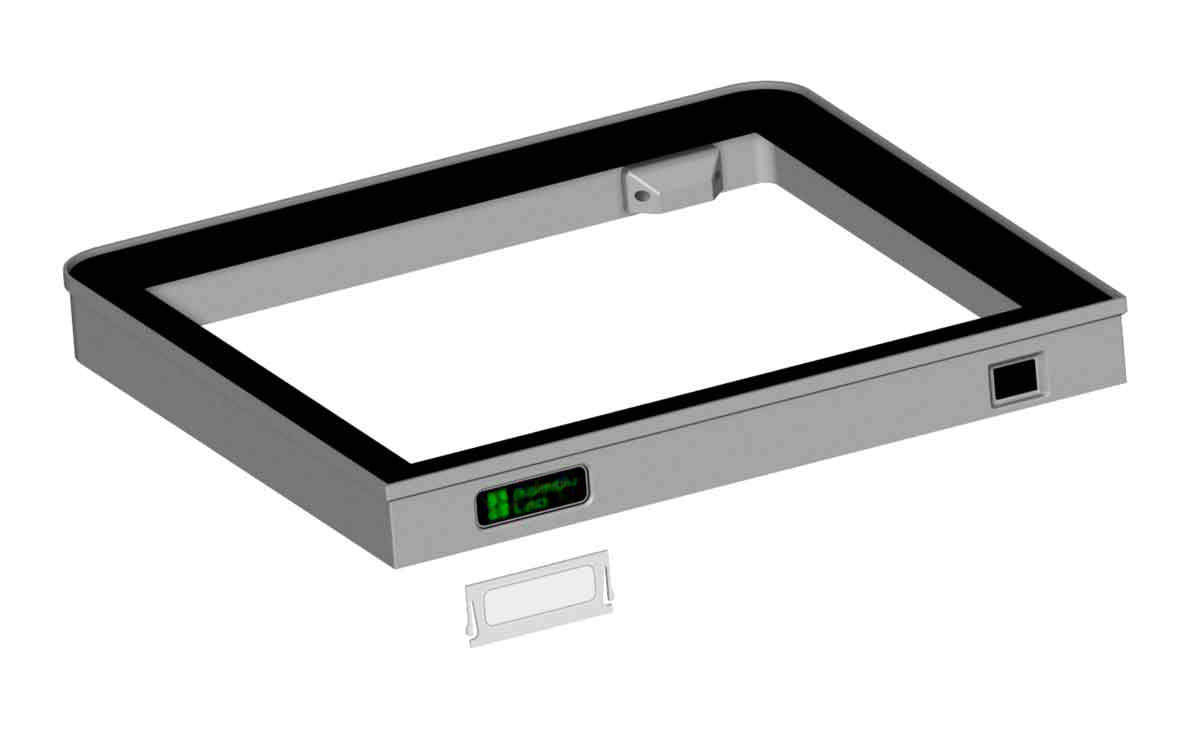

- Customizable label plate.

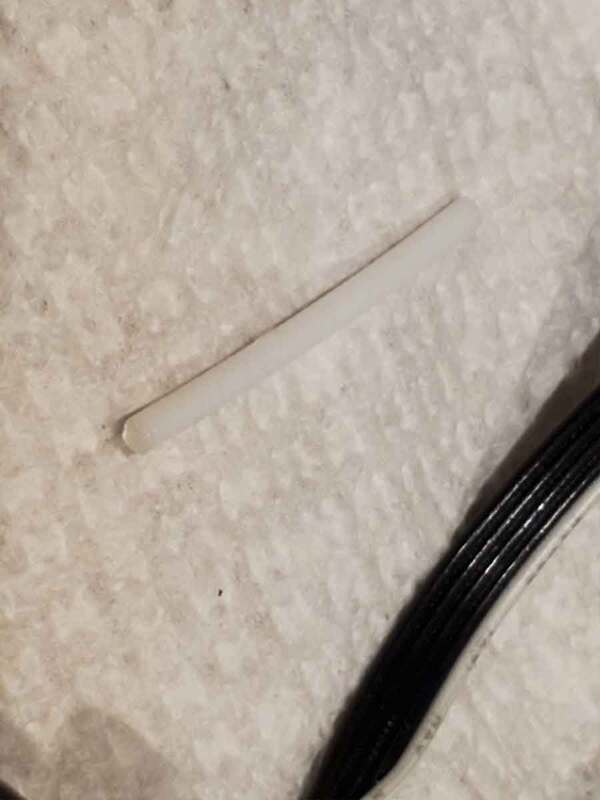

- Holder for the best tool for the Bambu printers with an AMS.

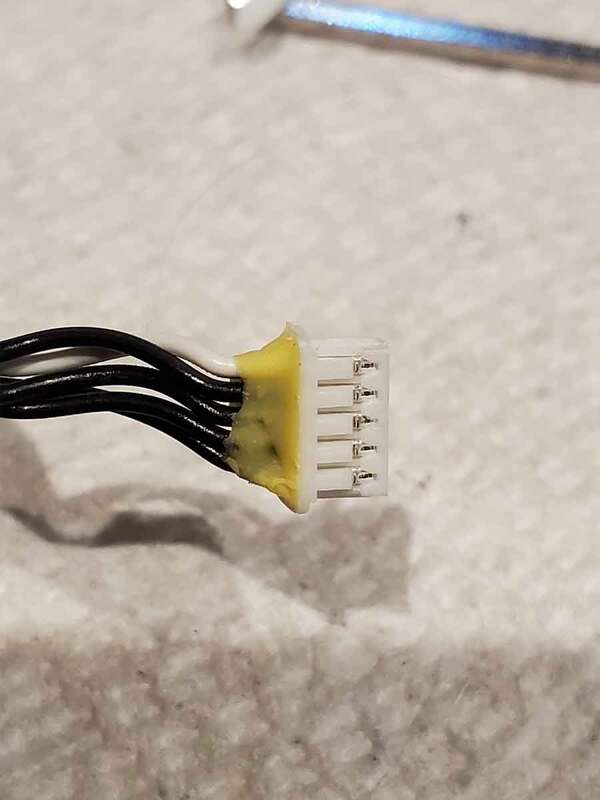

- A slide in frame to allow using a Brother P-Touch label to notate the voltage for the LED's (so the wrong power supply is not accidentally connected to them). The frame just covers the edges of the label and makes it look a bit nicer.

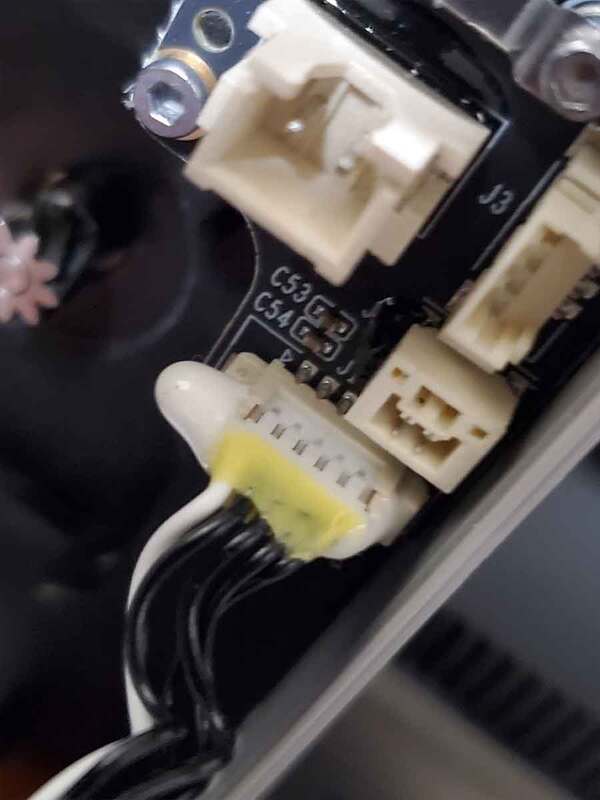

- There is also a DC input jack on the back, so there will be no wires hanging off the riser.

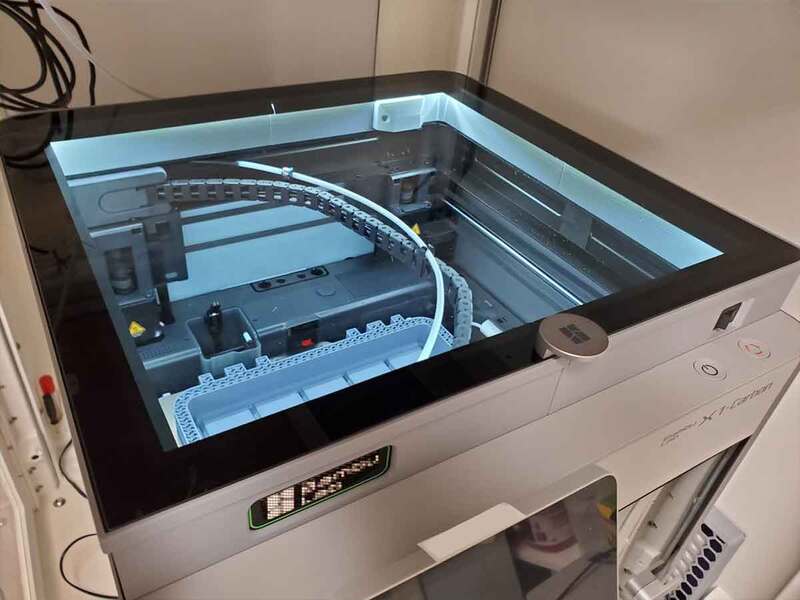

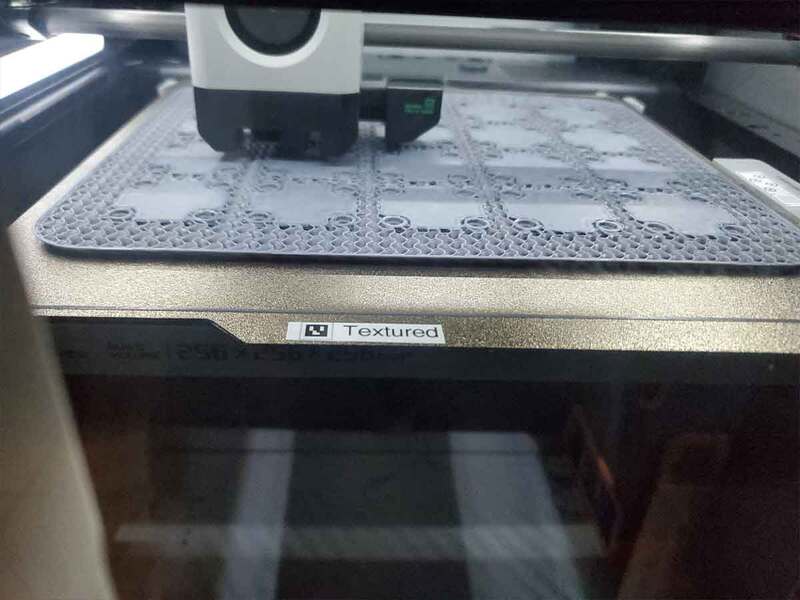

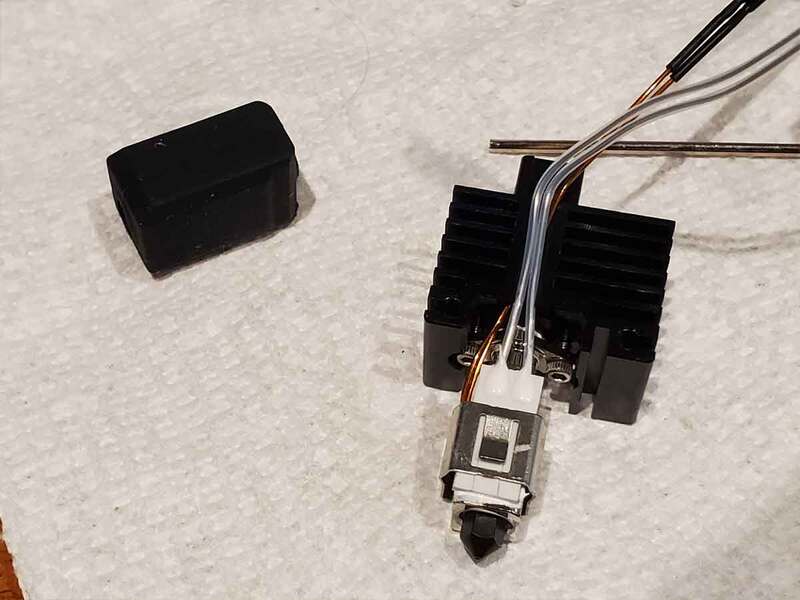

This prototype allowed me to update the design with some improvements related to installing the wiring. The holes were a bit too small so while I struggle to install them, the design which will be uploaded will have much more clearance. Other than that, its pretty much the same. I'm really surprised how well TPU prints on the X1C, though getting it off (the cold sheet) is difficult. I used the liquid bed "glue" as a release agent before each TPU print, and then dabbed on a bit of IPA to help remove the TPU parts, which helped.

RSS Feed

RSS Feed