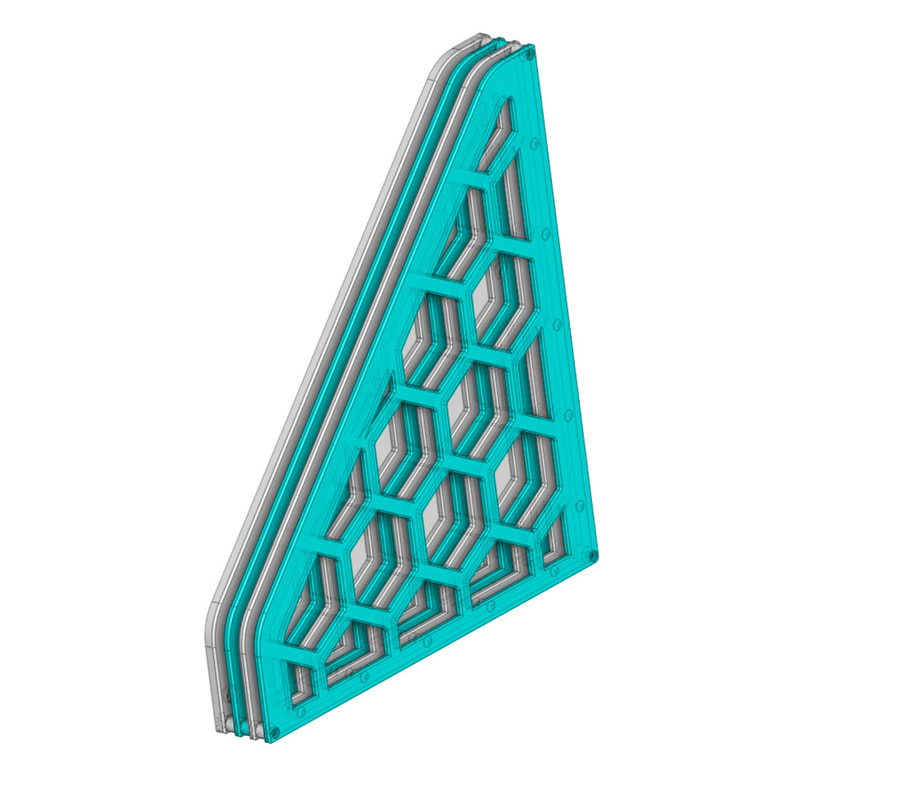

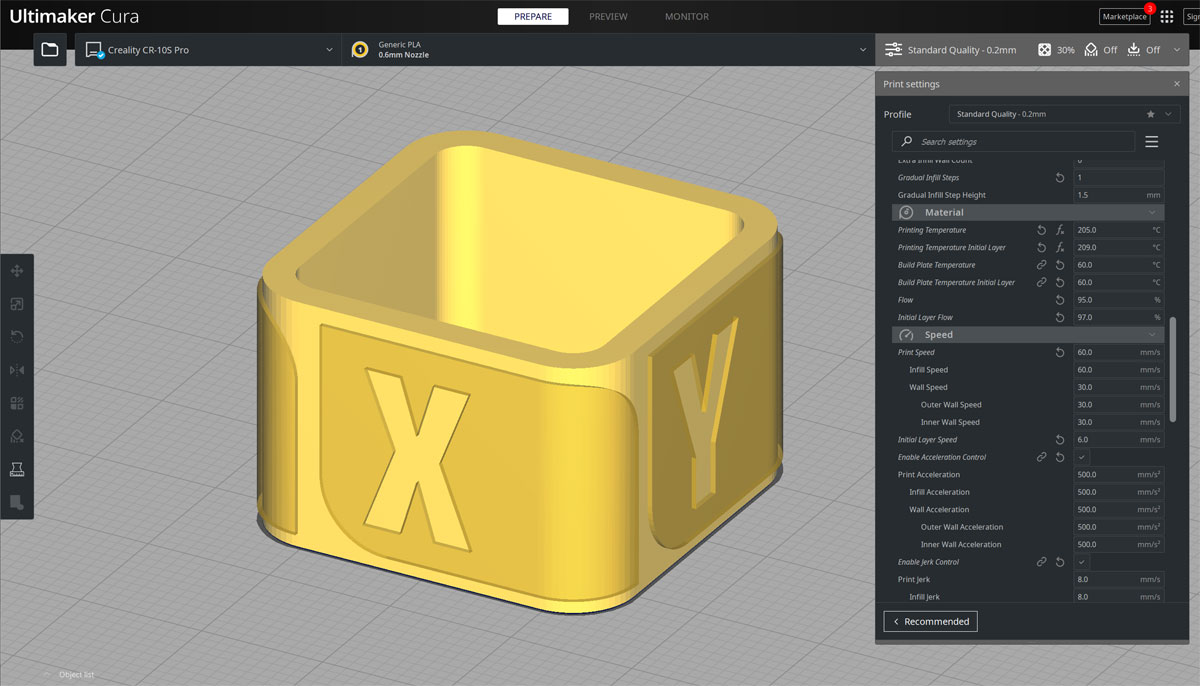

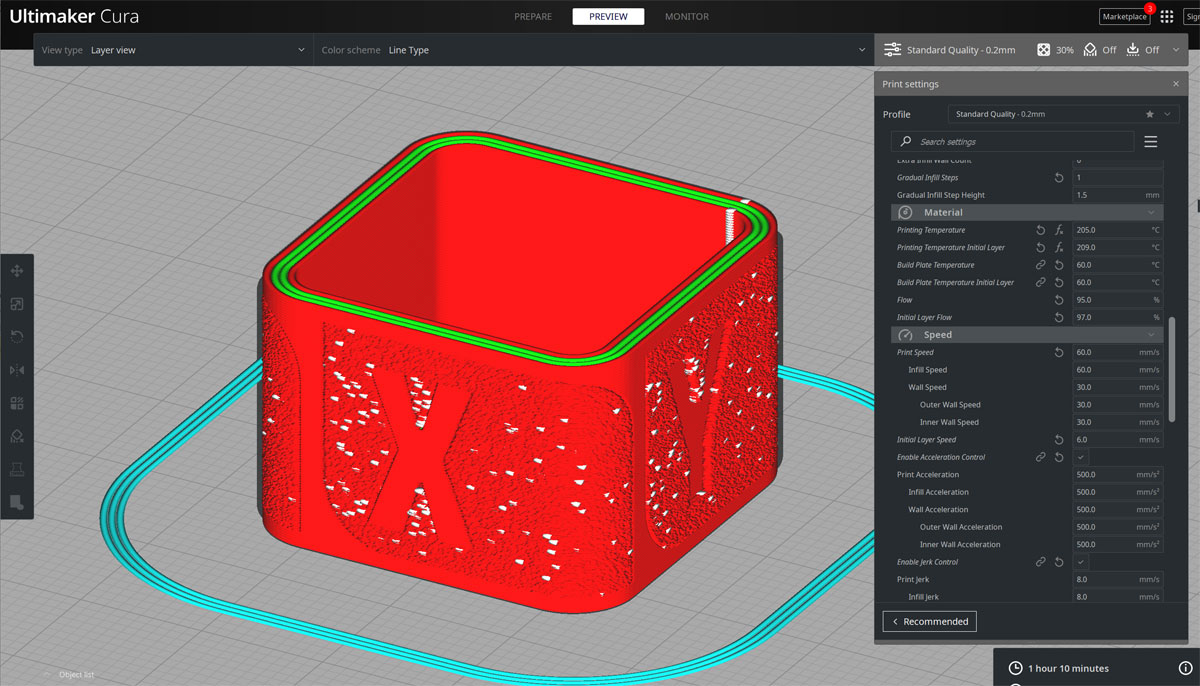

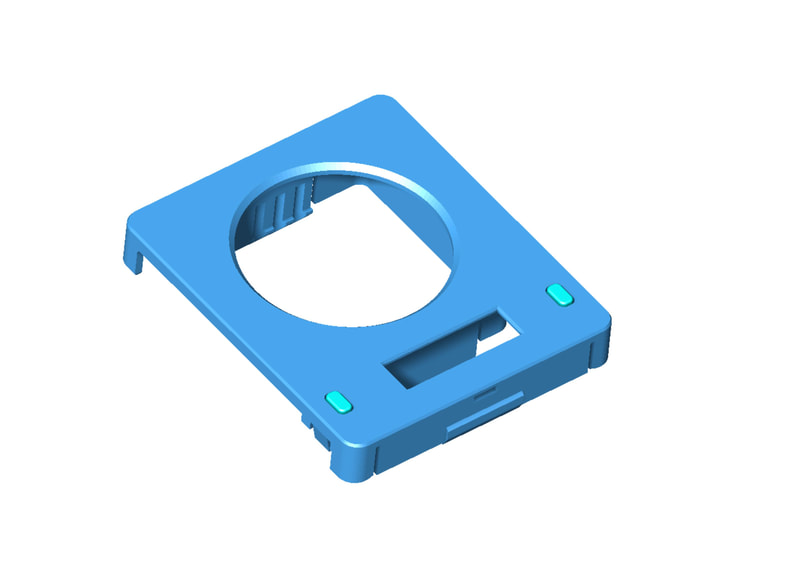

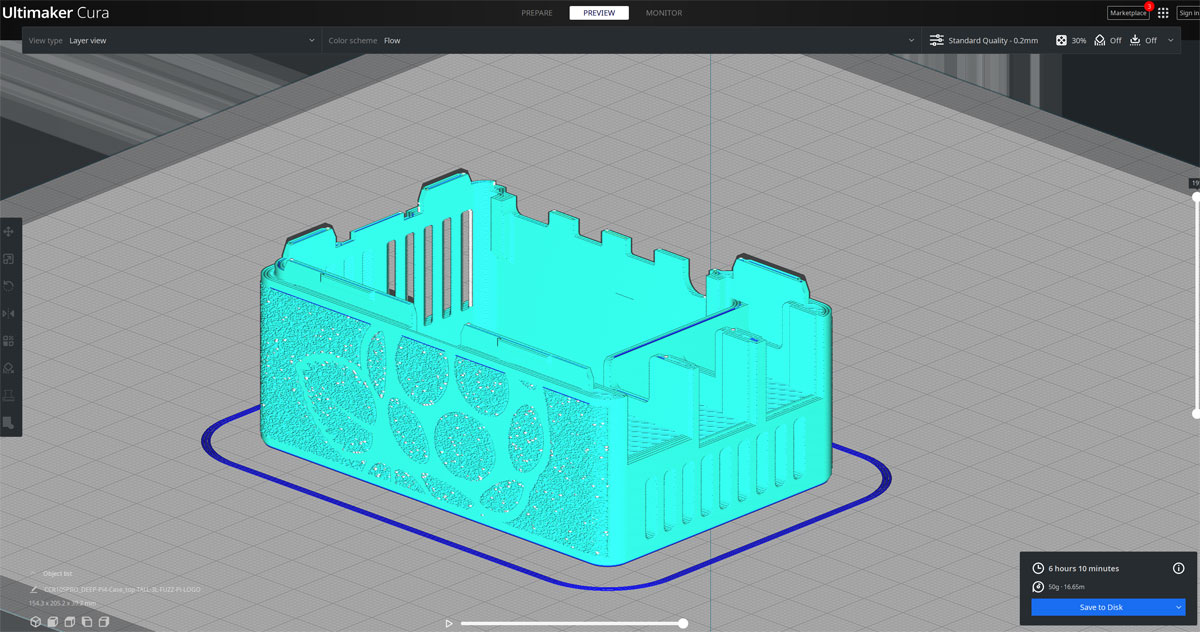

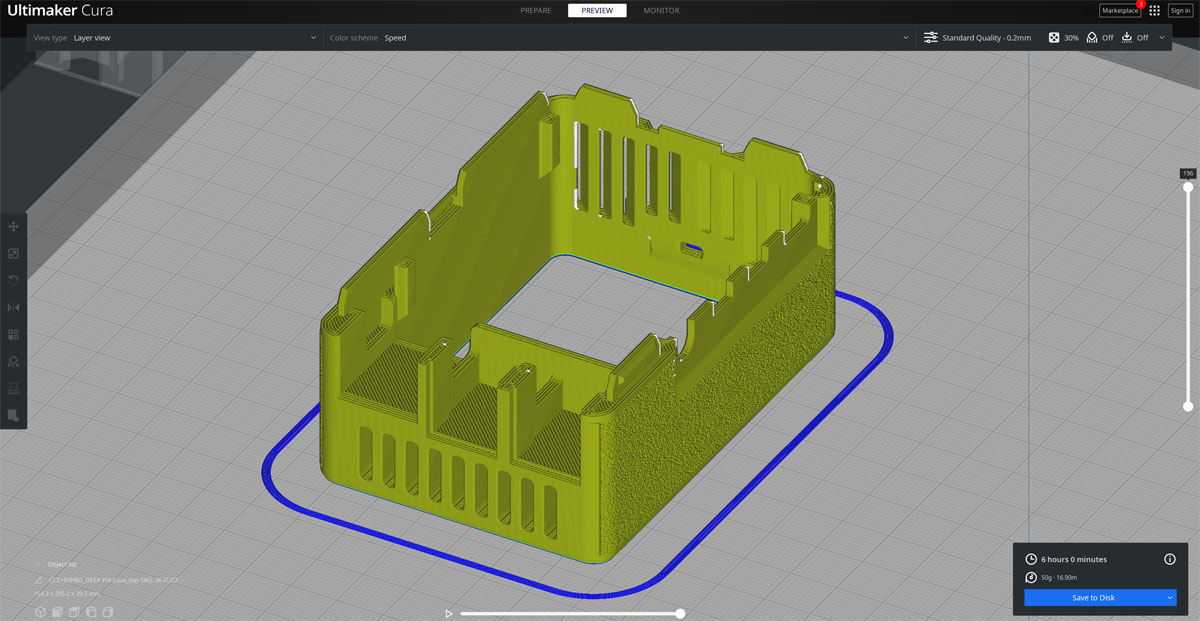

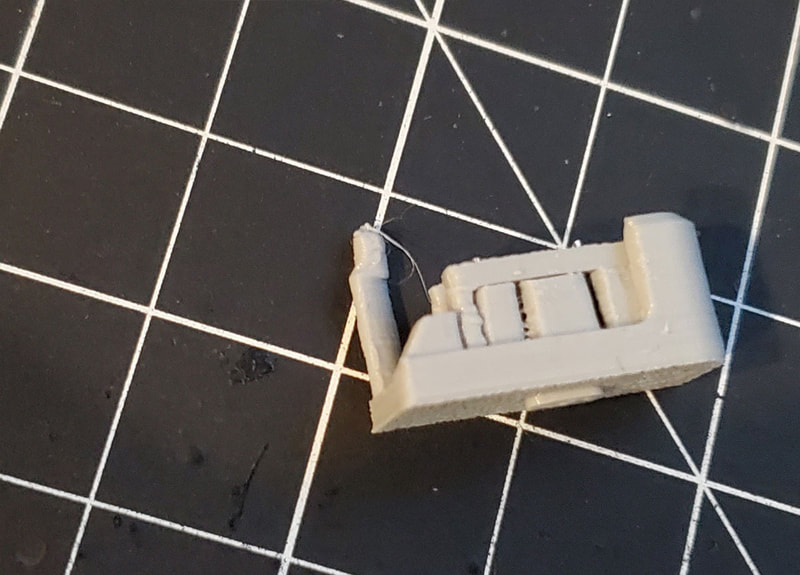

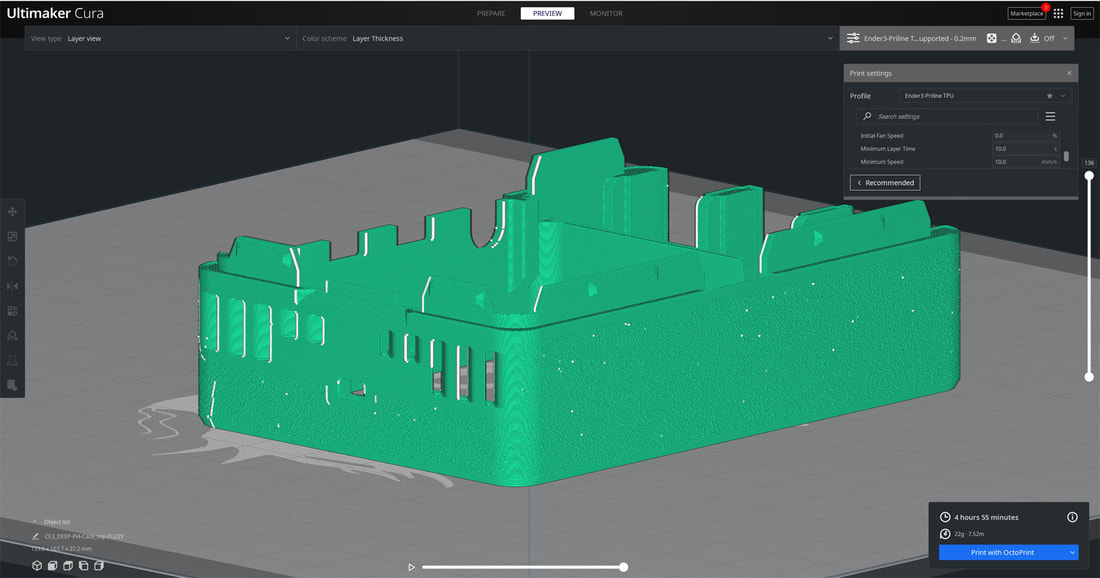

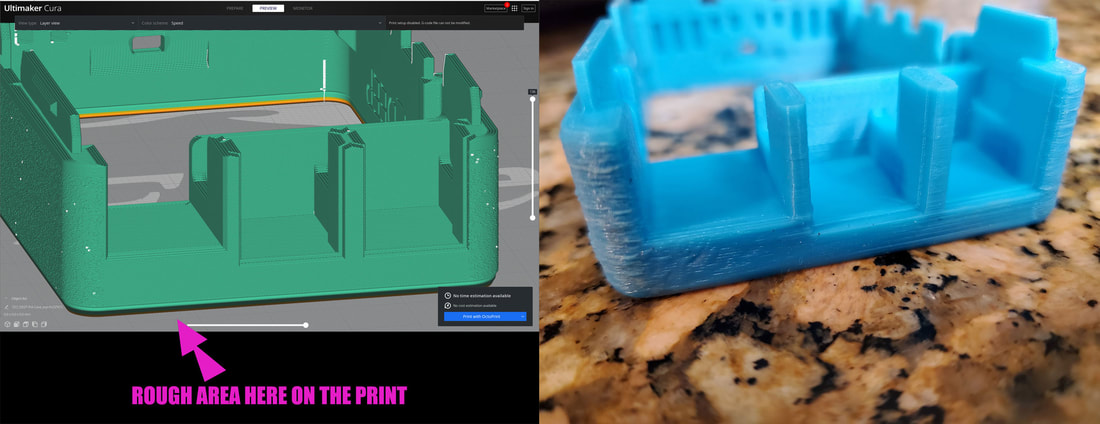

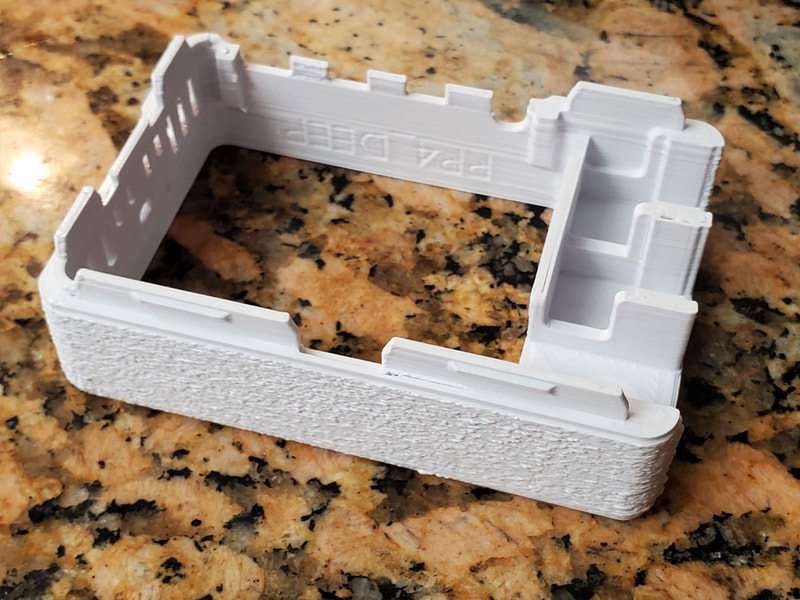

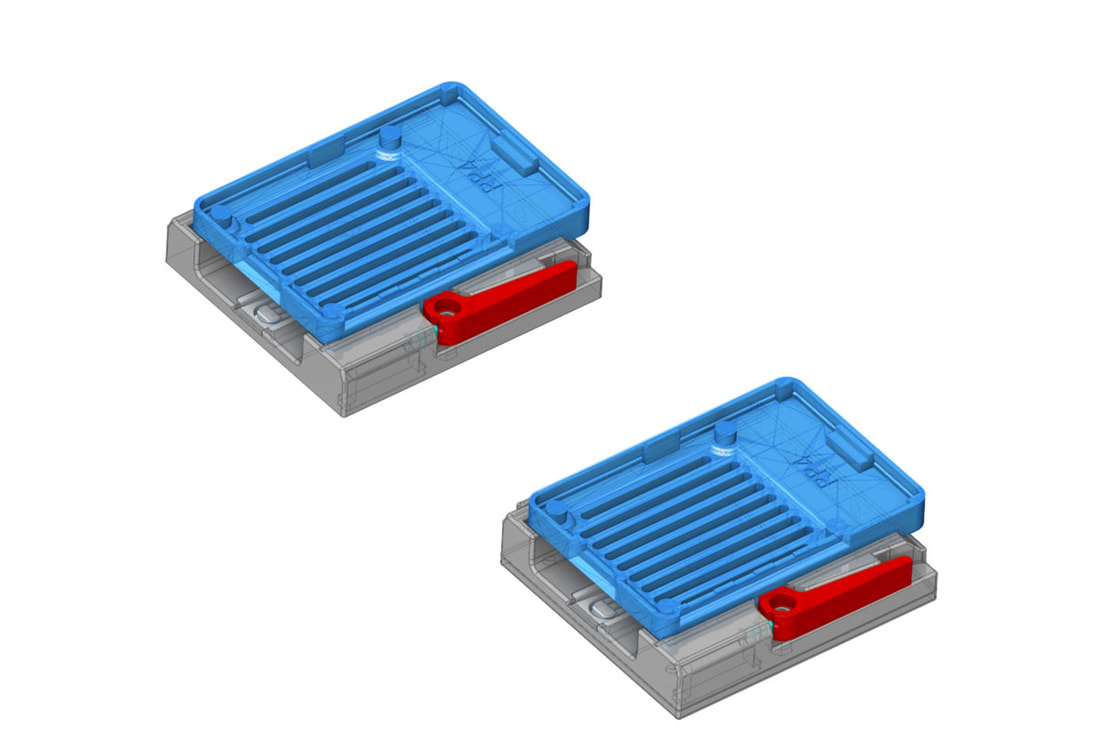

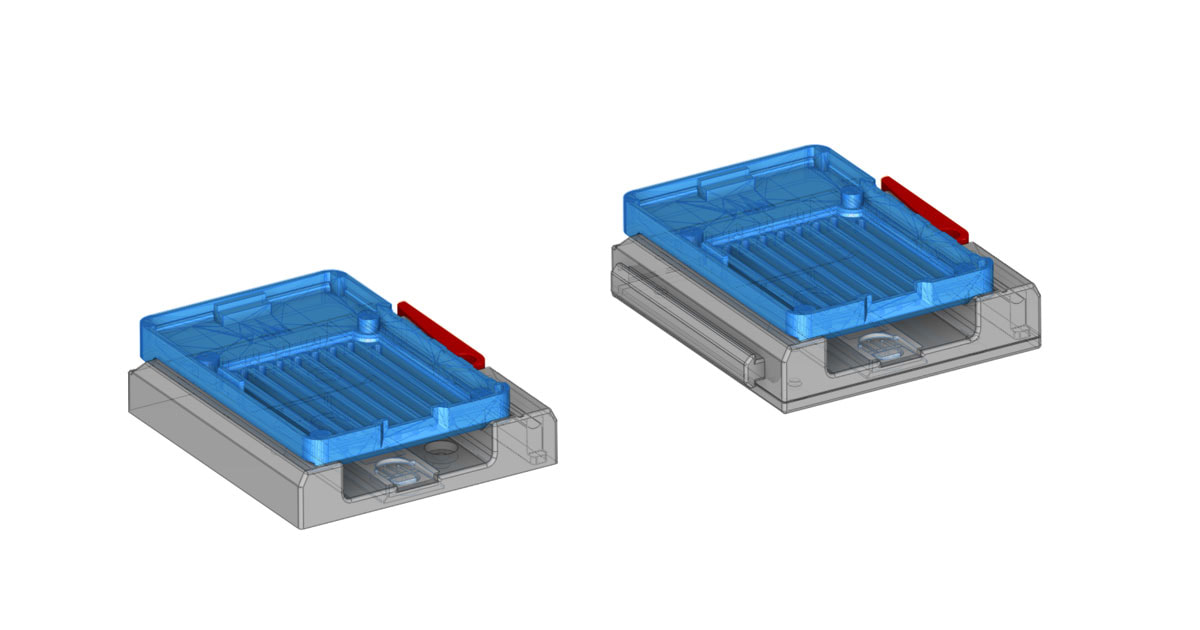

But this experience did give me some ideas on a more modular approach to this problem, which would take a more reasonable amount of time to print (each part). Hopefully I can get rid of all the supports too and give it a nice surface finish. So it's back to the drawing board, since I'm not into multi-day (or even full day) prints for various reasons.

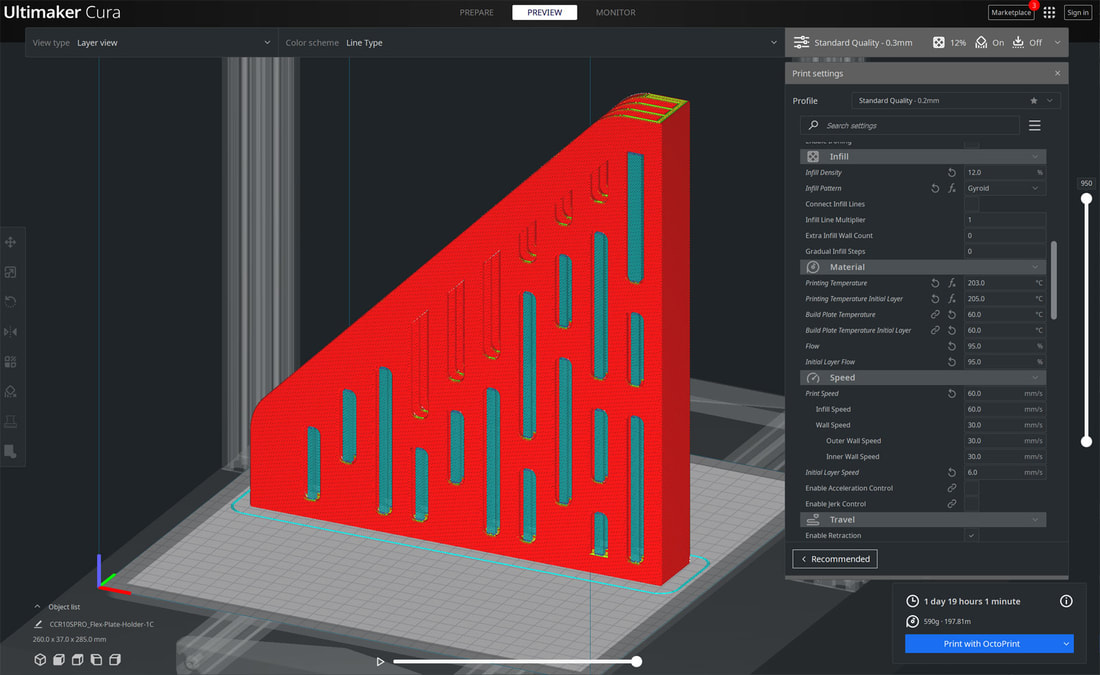

I'm still not sure though if I will tackle this print since it will take several days and I already have things going on, but will add this to the list. I need to get a safe storage solution for my build plates though...

RSS Feed

RSS Feed