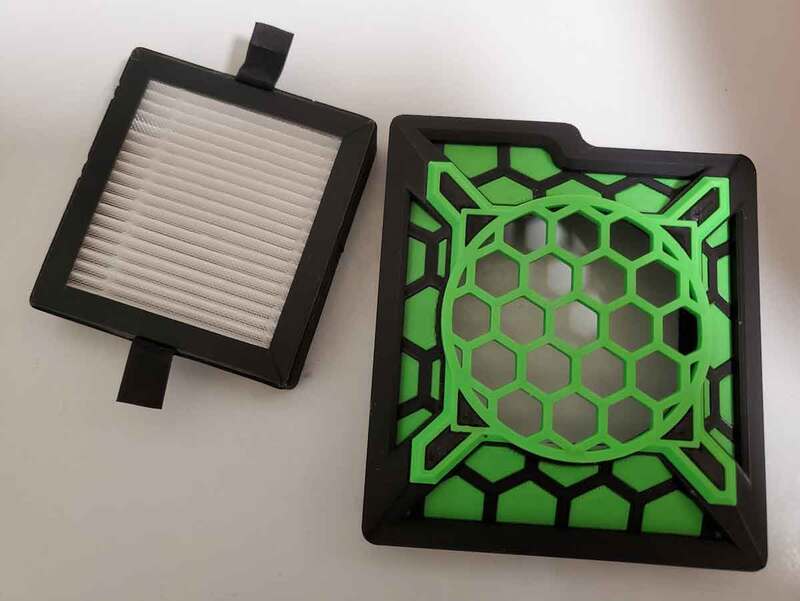

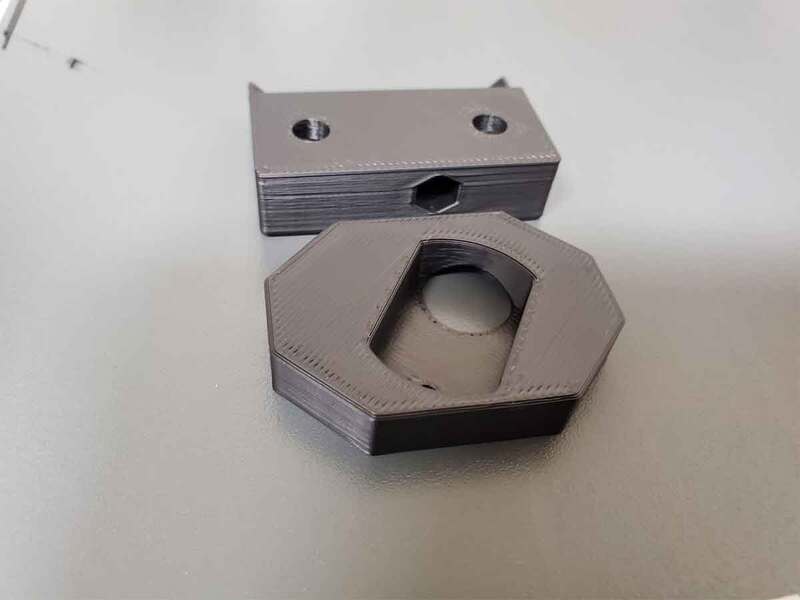

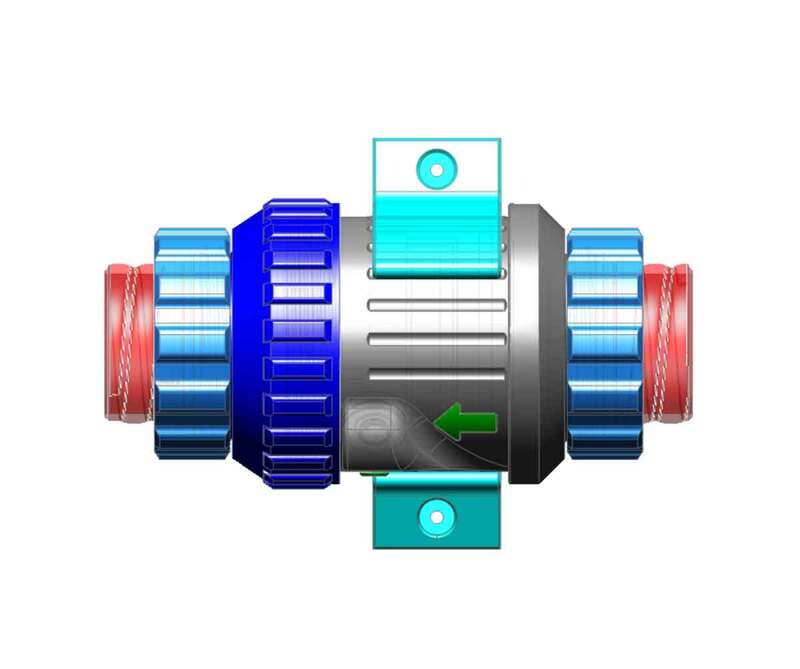

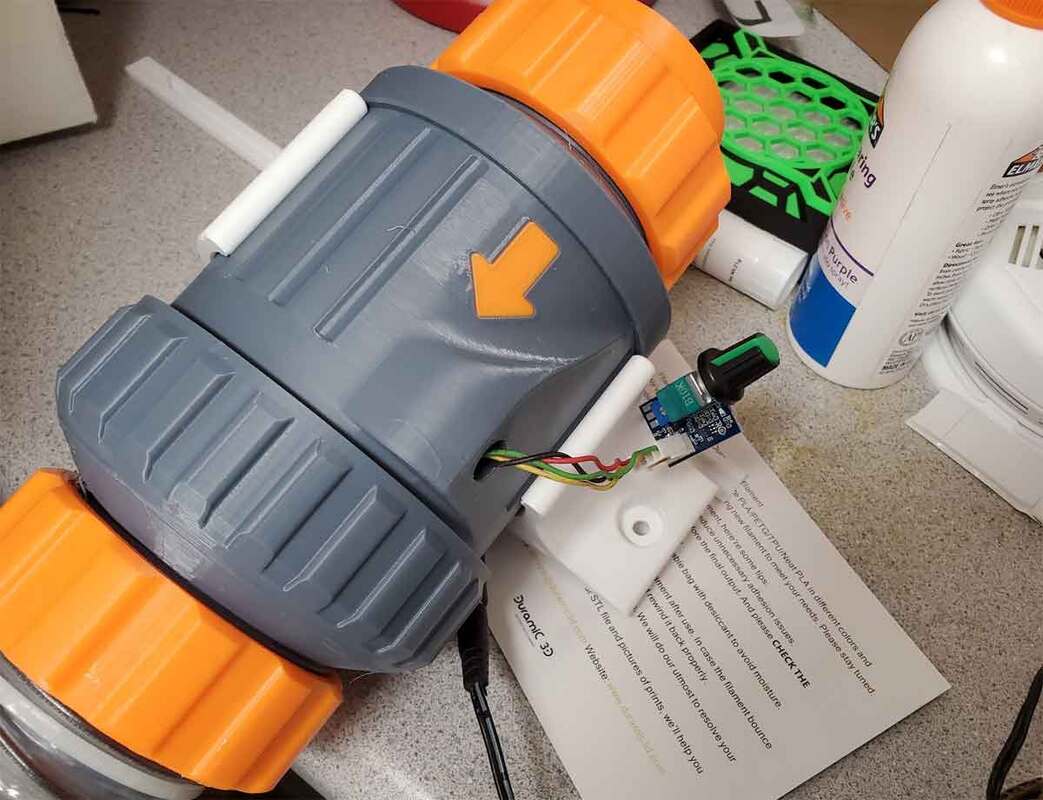

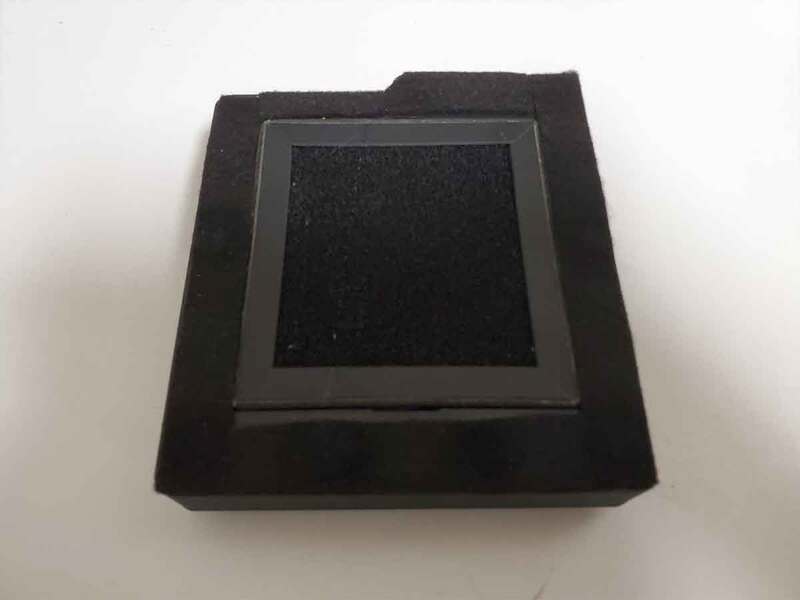

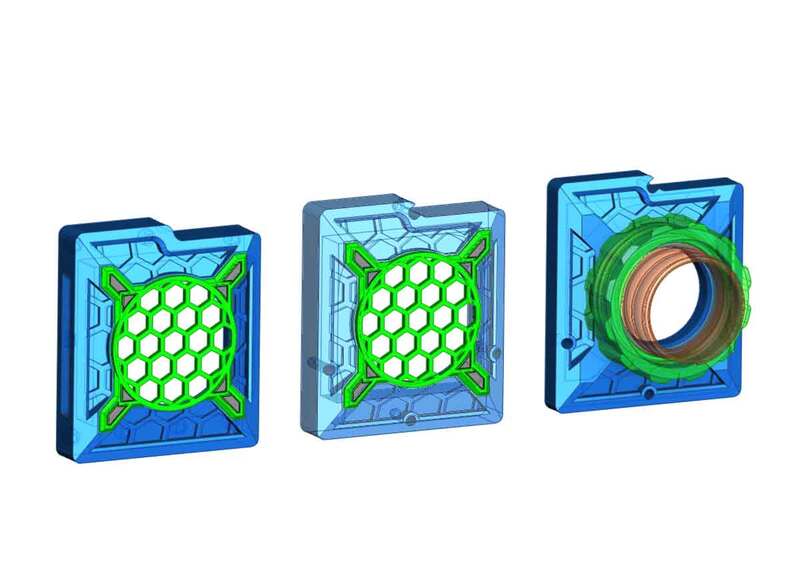

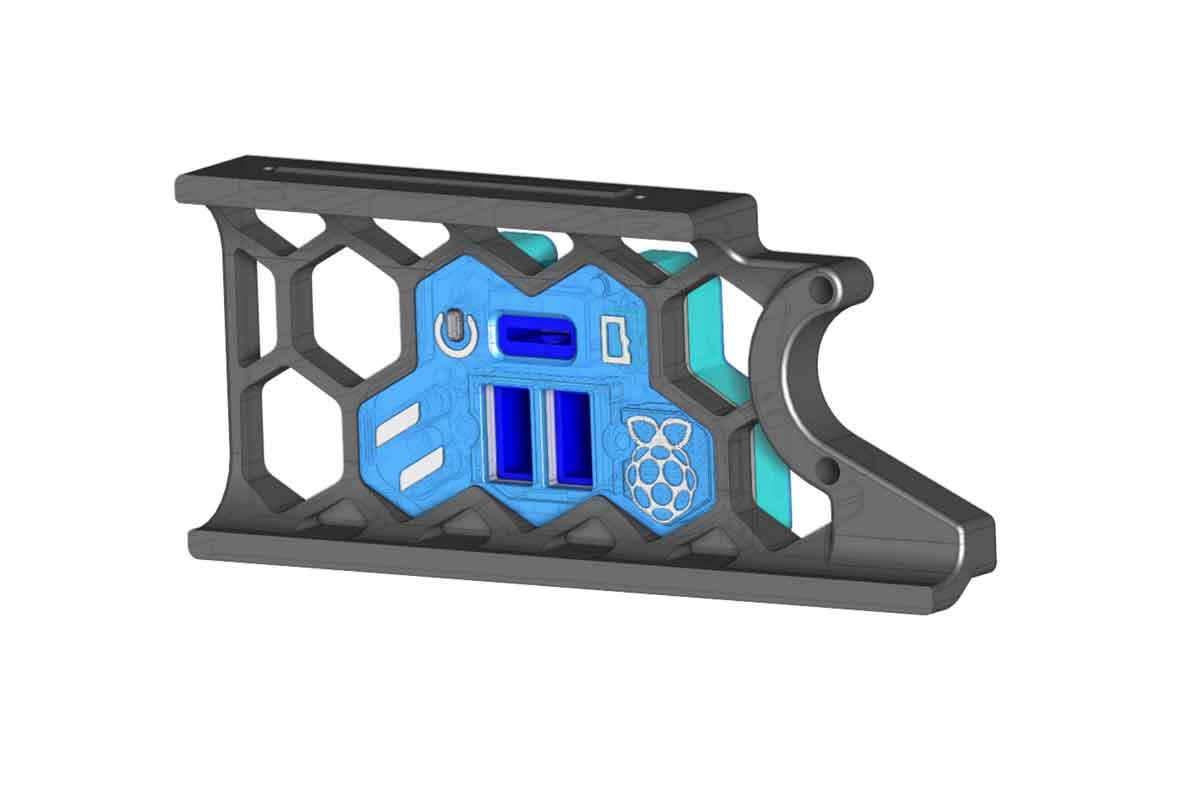

If the ABS smell is due to the leaky enclosure, why then does the fan stink? I don't have evidence right now, but I can feel with the filter in place, that the chamber fan is too weak, and the flow is uneven through the vent on the back (seem to be more flow on the left side than the right side). I need to see if I can find a filter that may work "better" with the stock chamber fan (will need to be thinner and probably less effective). I think a robot vacuum filter may be an option, but for now this design is going back to the drawing board. Still though, I'm planning on keeping the filter on the printer at least until I have something better, or I can get the vent ducting system built and installed. I could probably just put the X1C in the ducted enclosure I built for the CR10S Pro, but I could just as easily run ABS on that machine, so it's not worth the trouble.

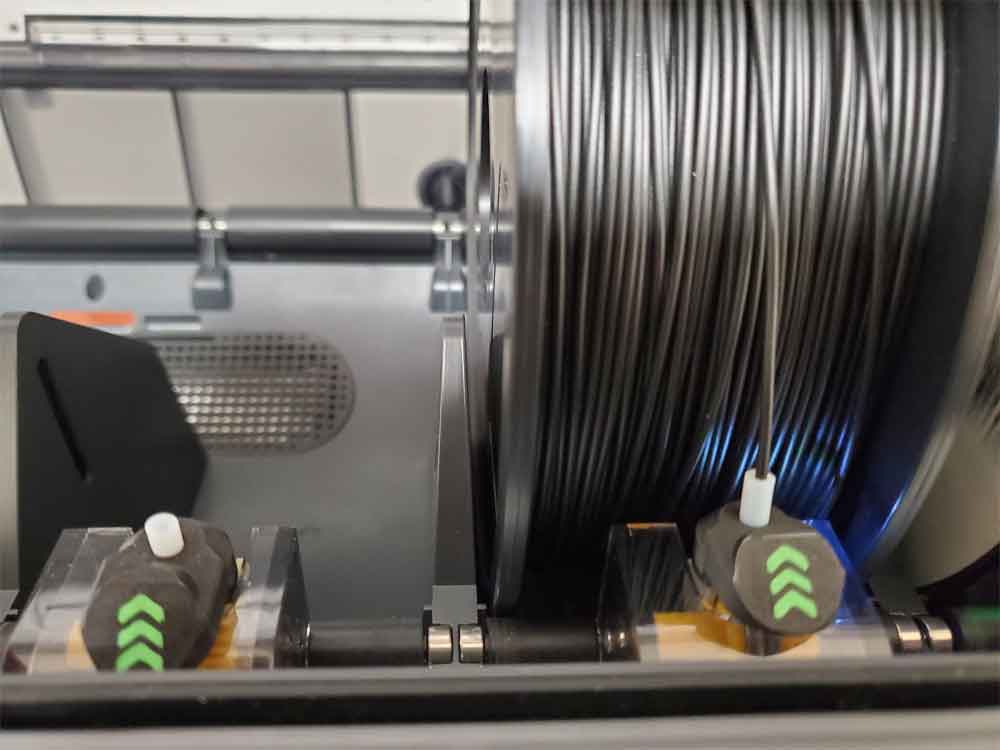

The X1C does print ABS decently though (without calibrating), and the enclosure definitely helps with the stink (though not enough). The slightly uneven layer lines in the pic below does not show up when looking at the parts, which have an apparently good finish (just not as good looking under magnification). That's not uncommon for 3D printed parts however, perfectly stacked lines is a sort of holy grail, and hard to expect without doing any calibration, aside from the out of the box stuff. I'm fine with this for prototyping stuff.

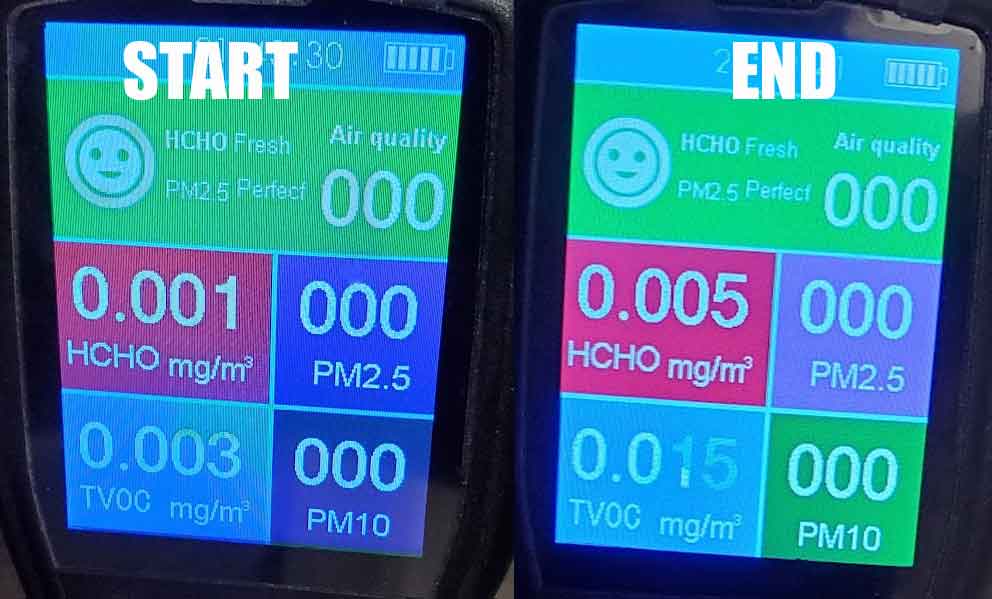

Edit: Maybe it could work for PLA, but no way will it be enough for ABS. I ran some PLA with it and did feel a very slight airflow though it when I had the chamber fan on 100%, so some air (but very little) is moving through it. I think it could be improved.

Edit 2: Nope, after running PLA for a few hours with the chamber fan at 80% the whole time, it still has a funky sweet smell of printing the stuff. Gonna wait for the parts to make a duct system, and may stick the printer in my other enclosure in the meantime.

RSS Feed

RSS Feed