www.thingiverse.com/thing:4164450

|

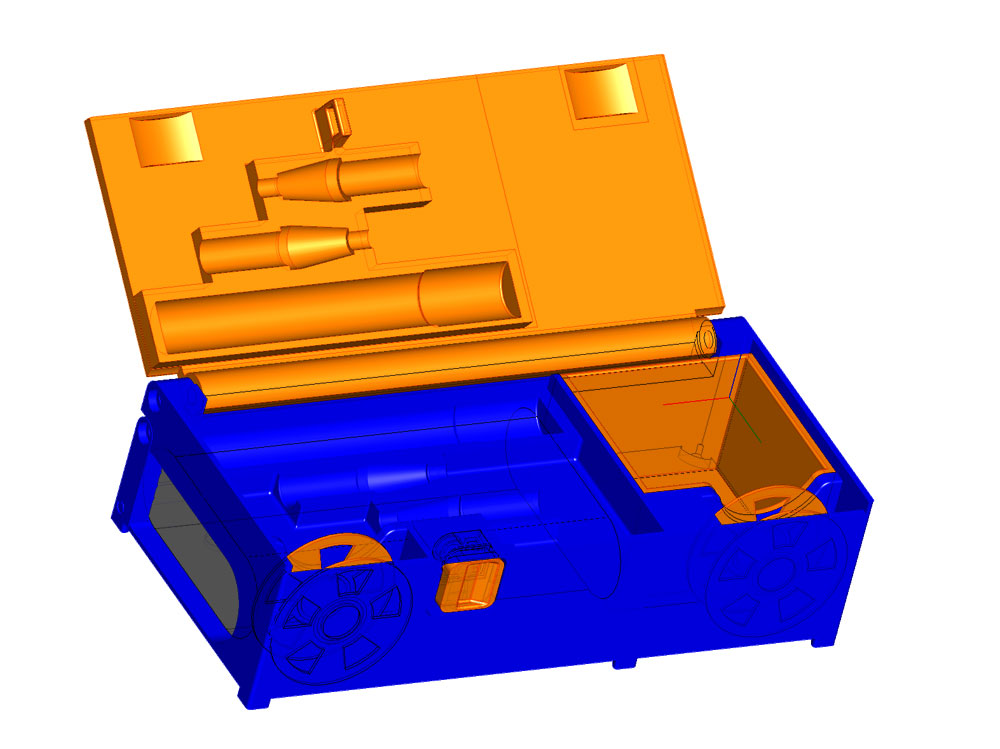

This is just a quick remix of the TS-80 case I made a while back. This one is larger though, so a USB cable can be stored in it. It is now posted on Thingiverse (but not yet tested):

www.thingiverse.com/thing:4164450

0 Comments

So I swapped the worn stock arm on my extruder with another of the same design (which fixed the looseness of the non-driven gear), but that did not fix the underextrusion. I also replaced the bowden tube and coupler which helped a bit. Although I swapped the nozzle twice previously, the last couple were cheap MK8 brass nozzles which were from the same batch. So now I have swapped the nozzle with this one from Amazon, and from the looks of it the problem is almost resolved. The PrimaCreator nozzle is not the cheapest at about $6, but also not the most expensive. It's also not plated, just good old brass, but it looks really well made. I did not see any burrs, and it appears almost polished on the inside. I did not get pics unfortunately before I installed it, but the hole in the nozzle looked as good as any of the more expensive ones - though I only have a magnifier and not a real microscope to check it.

The test cube I printed with it is a definite improvement over the last one, and is acceptable now. Still, the first print with it was not perfect (had some boogers which I typically do not see with the same settings) - but I am still testing it. I have some longer prints lined up which should be a better test for the nozzle.

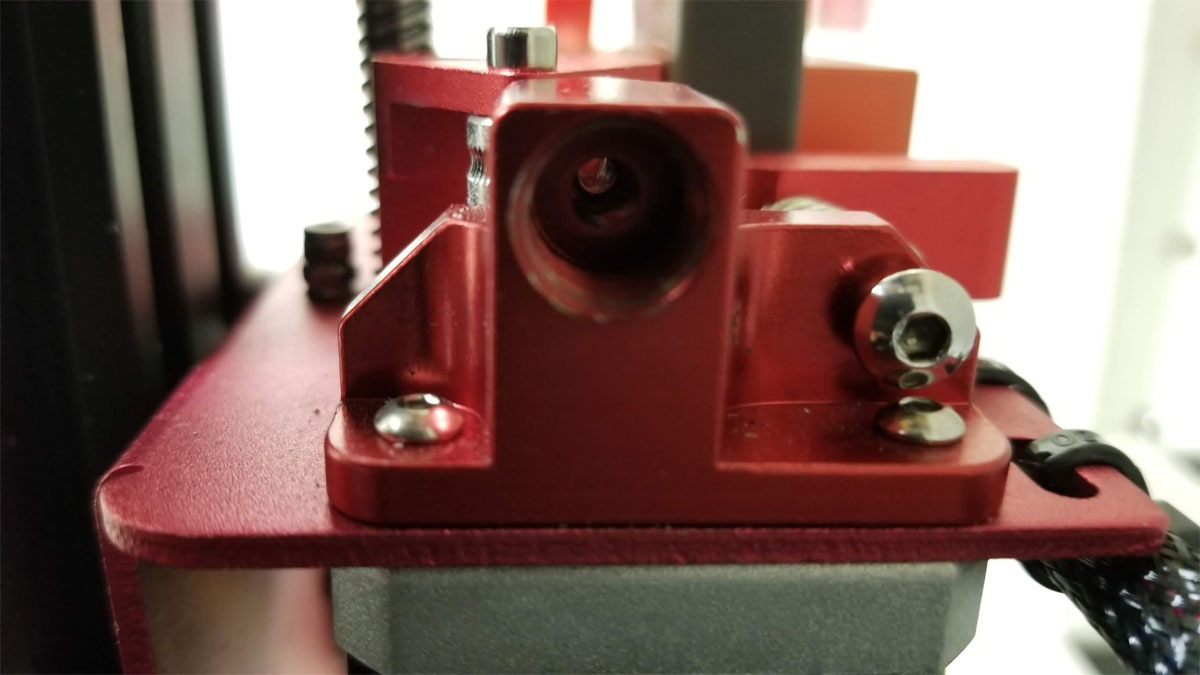

After months of great service, the CR10S Pro now needs some help. It was poorly extruding, so I tried swapping everything out from the nozzle to the bowden (and couplers), checking extruder steps, tearing down and rebuilding the hot end and checking the filament diameter, and then found this:

The arm is clearly worn from the gear rubbing against it. I'm not 100% sure that this alone is the problem but it certainly does not look great, and I need to fix it. Update - it looks like it is not 100% of the problem, I was able to reduce the underextrusion quite a bit by removing and re-installing the bowden tube again (suspect that the tube was not fully installed in the extruder. The problem with the extruder arm however will need to be fixed or replaced.

But there is a fix, provided by TinyMachines (Updated Link 10/20/2020 - https://tinymachines3d.com/products/creality-10s-pro-modified-extruder-lever-1?_pos=8&_sid=06017859e&_ss=r ). They will mill out the lever and provide some bronze washers for $12.50 (plus shipping). It is cheaper to get a new dual gear extruder from Amazon, but it looks like many of those will probably have the same trouble in time, so this is a better fix if the idea is to keep it stock.

Updated 10/20/2020 - looks like they now just sell the replacement levers and don't require the old one to be sent back. The cost ($15) is actually less when factoring in the shipping cost to send in the old levers.

There are certainly better options for direct drive extruders, but right now I just want it working again and don't have the time to spend installing a Bondtech of Titan (which require firmware and vref changes). Not sure what the turnaround time is on it though. And here's a great video which explains the fix from Liqui-Dirt 3D.

Update #1 (2/4/2020): I swapped the arm of the extruder with another which was not worn (bought a spare which is nearly identical and has the same dimensions on the arm). It did not help, so now I am leaning to the nozzle since I recently swapped to a cheaper set, and although I swapped it, it was with another nozzle from the same batch. The problem did not immediately start with the nozzles though so I am still not sure. So next up I am gonna try a better nozzle and see if the problem continues.

Update #2 (10/20/2020): Updated the link (thanks Sam K) and found that they are now selling the replacement level which includes the fix. Also, I found the original issue was due to the bowden tube not being fully inserted into the extruder. The extruder has a smaller diameter pocket designed for the bowden to extend in several mm further than the end of the coupler (see the pic below). Because this pocket is not beveled and is about the same diameter as the bowden it is difficult to get it to extend all the way into the pocket (gets caught on the tip of the bowden tube). I have trimmed a slight bevel to the outside of the tube which helps somewhat but its still a bit of trial and error. If there is a gap then it can also cause an unusual clog which cannot be removed without removing the coupler from the extruder (makes a pigtail of wound filament in the gap). If the bowden is fully inserted however there should be no problems.

The extruder arm will still get replaced once I get the fixed one from Tinymachines since I can see definite wear on mine (and the gear can now move a bit over a mm up and down in the arm due to the problem), but the worn arm does not seem to be the problem in this case.

|

Stoopid MeWelcome to my Stoopid corner of teh Internet. It's mostly gonna be 3D printing stuff, but I also post some recipes, projects, and the occasional rant here as well. More Stoopid stuff is updated regularly. Archives

July 2024

Categories |

RSS Feed

RSS Feed