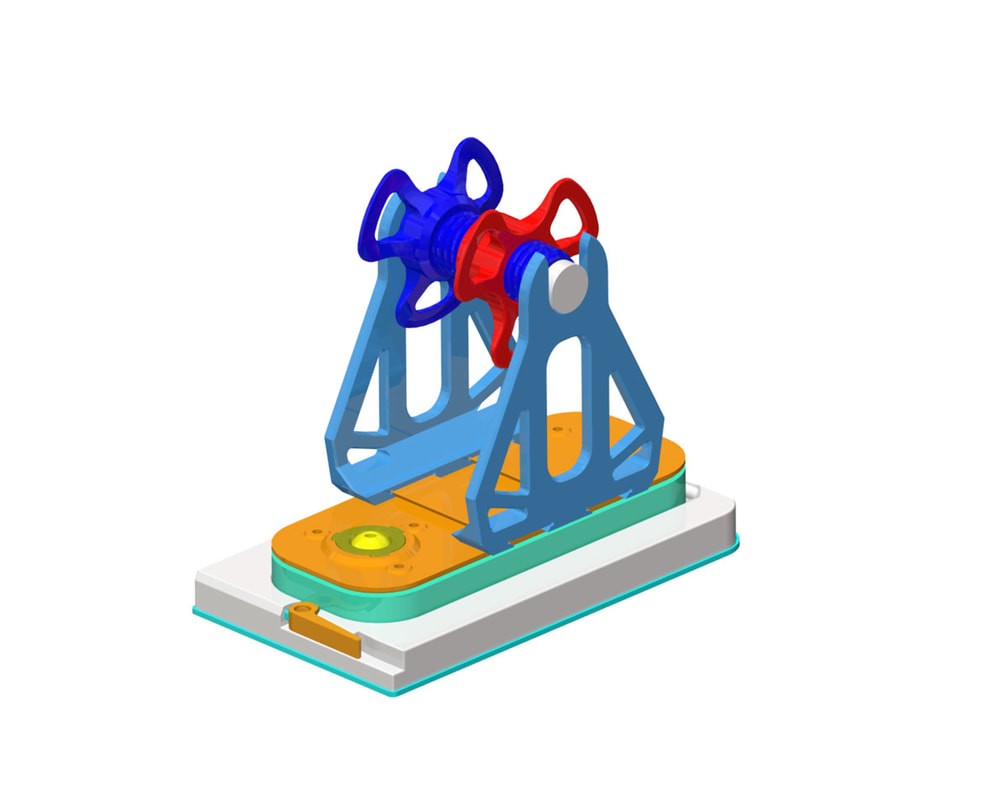

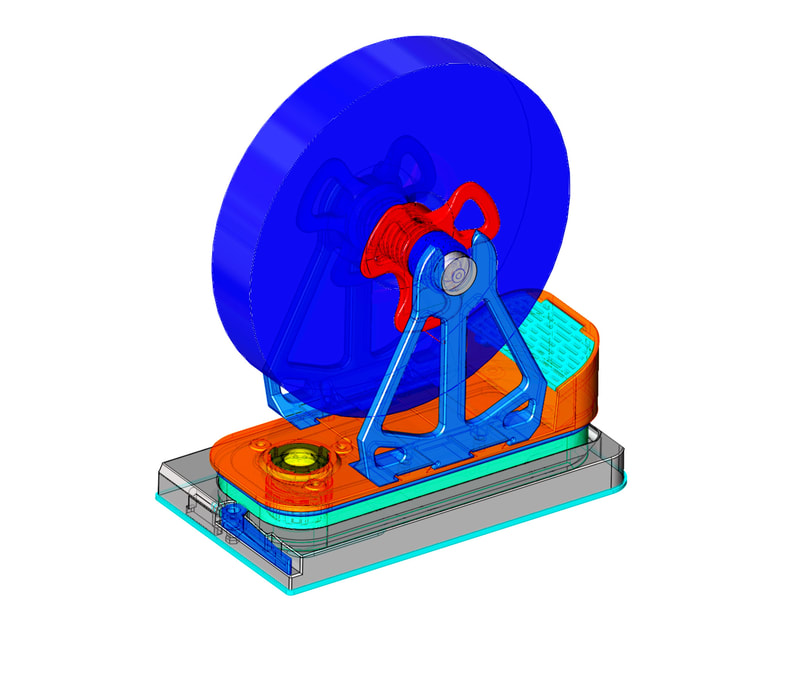

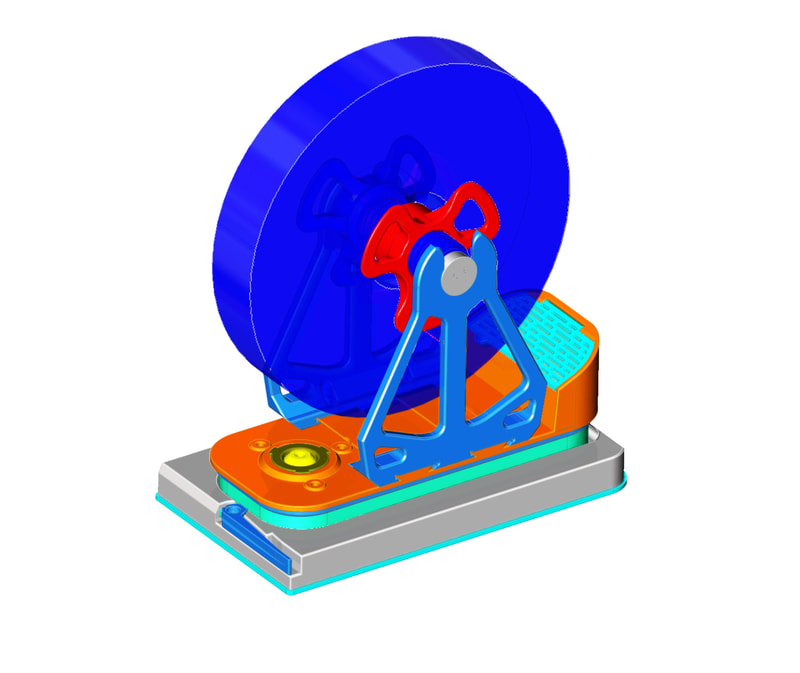

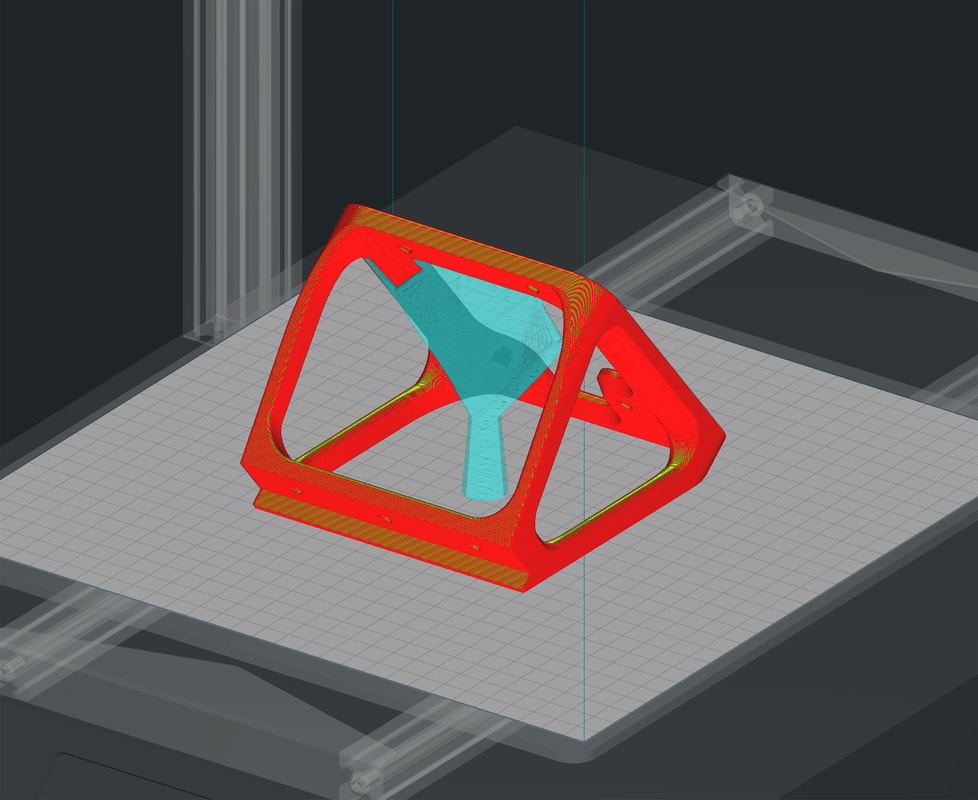

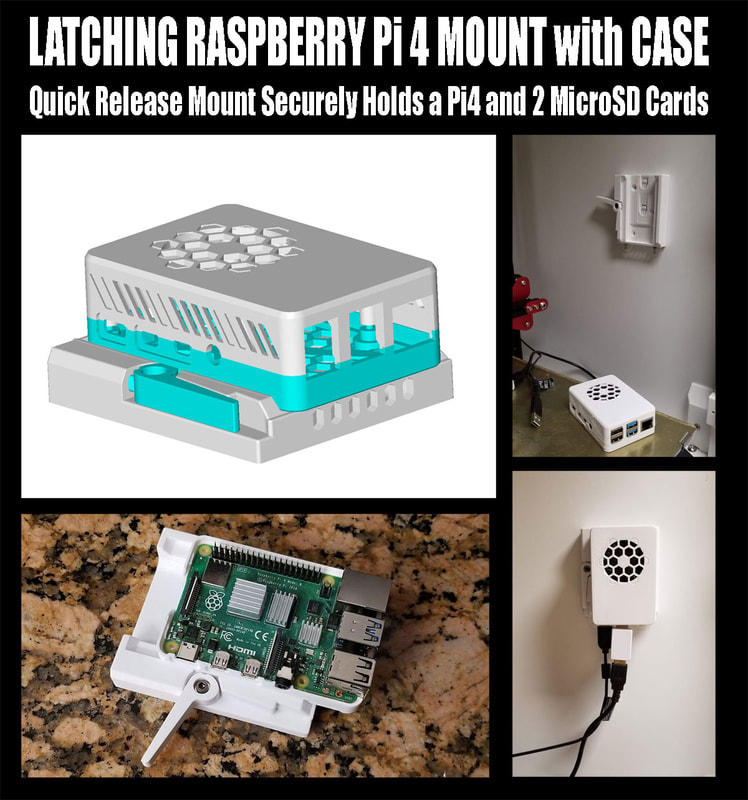

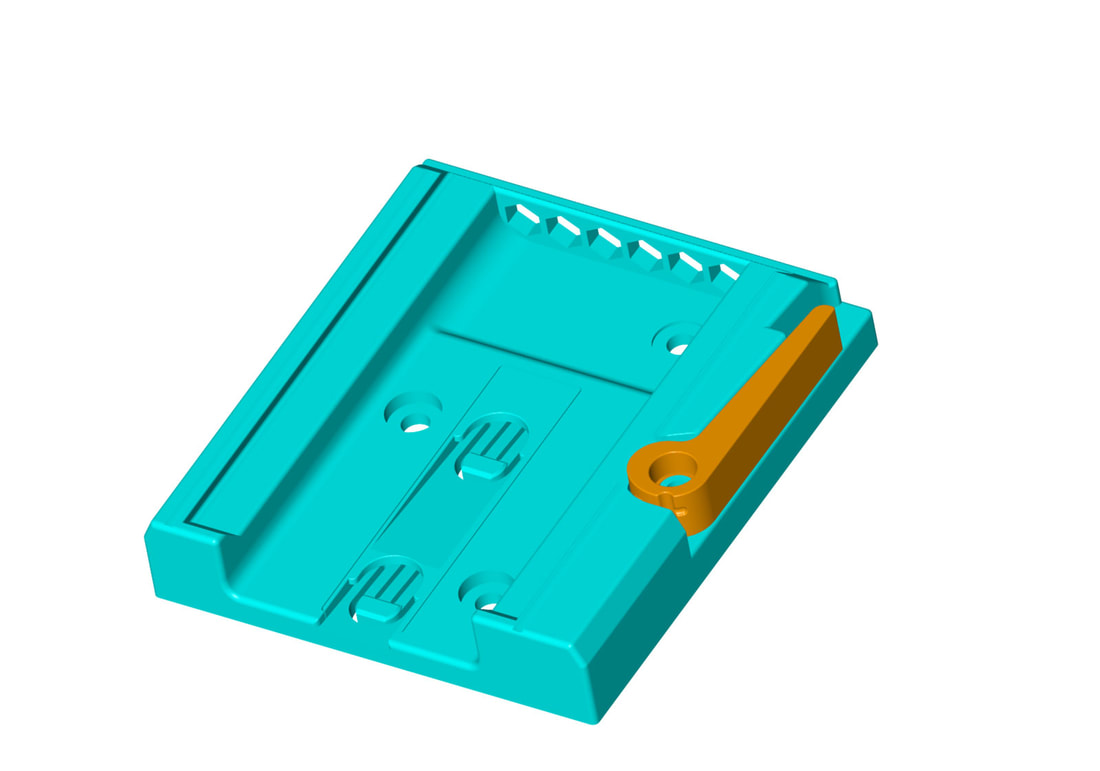

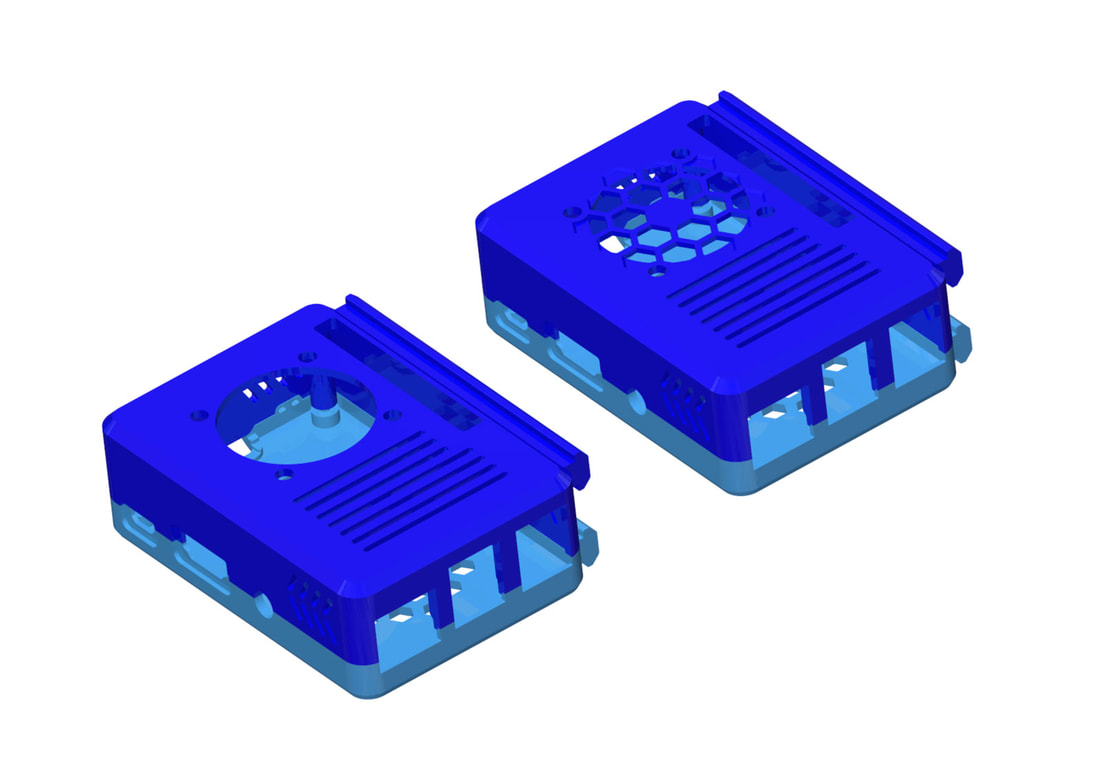

Updste 2 - 8/29/2021: Doh! After uploading the pics I noticed that I chopped part of the threads off the base, which has been fixed, along with a few other optimizations for printing. I have shaved several hours off the total print time by adding some holes here and there, and decreasing the thickness of parts in non-critical areas. The first prototype is not much to look at, but everything works as I'd hoped for the most part and where it has some issues, I'm hopeful the current version will fix some minor annoyances. I still expect this to be done in about 1 to 2 weeks, and then it will be posted to Thingiverse.

Update 3 - 9/1/2021: I had to make some changes but the design is now tested and works. It will be posted to thingiverse in the next week and I will add a link to it below.

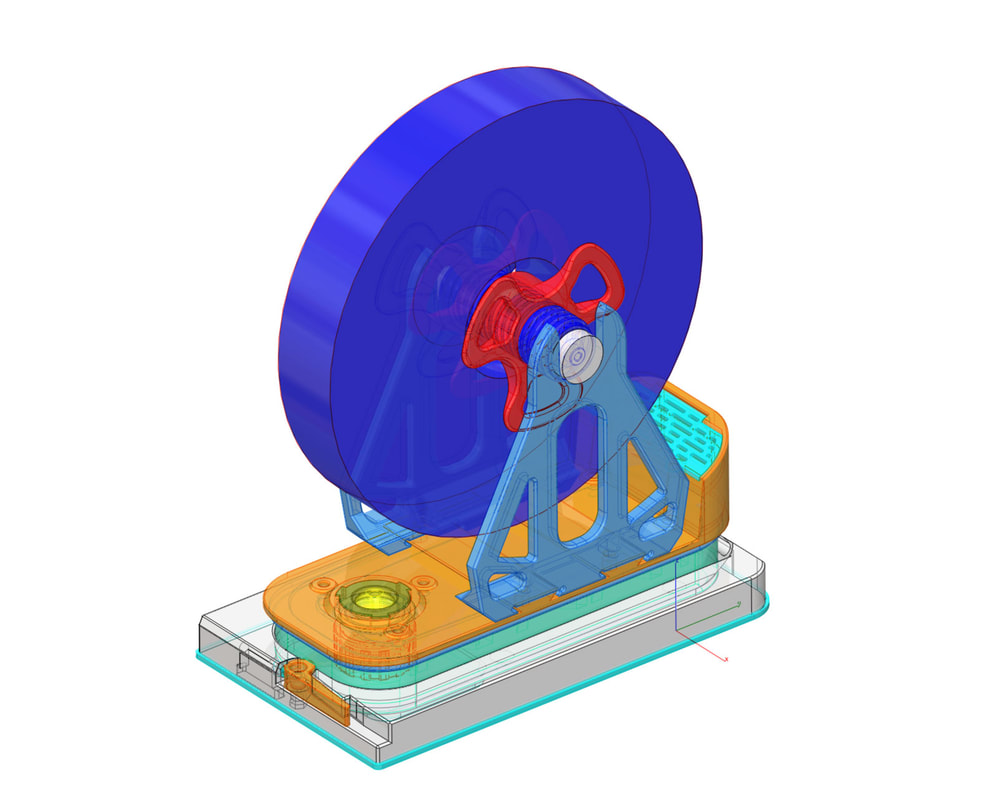

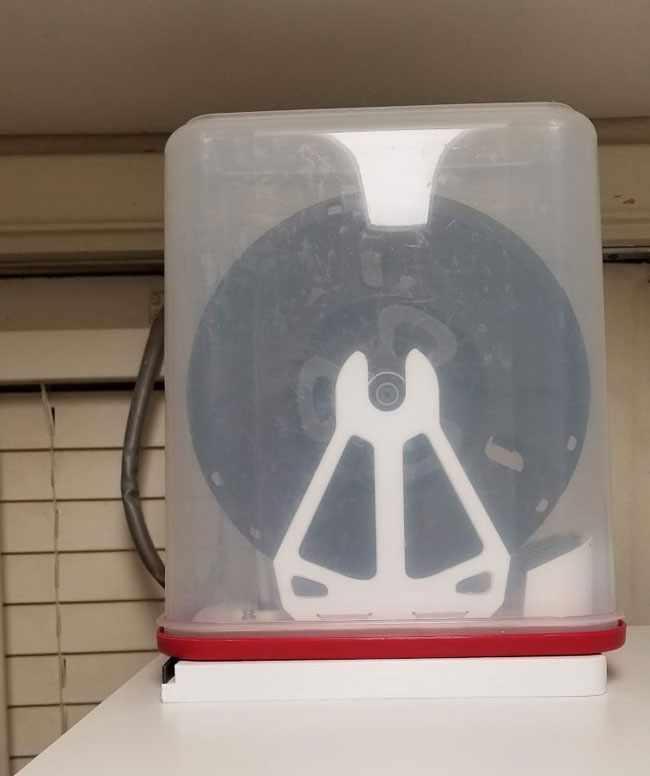

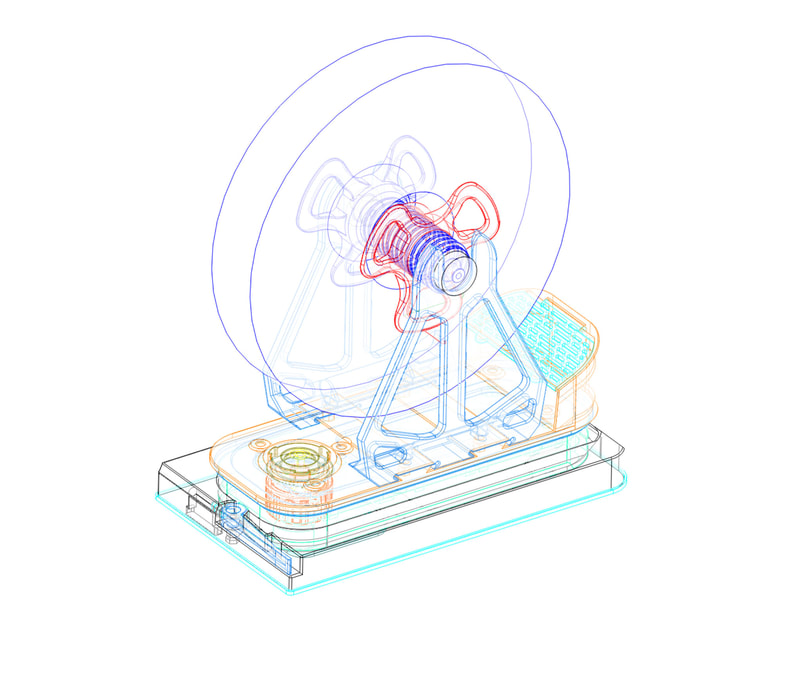

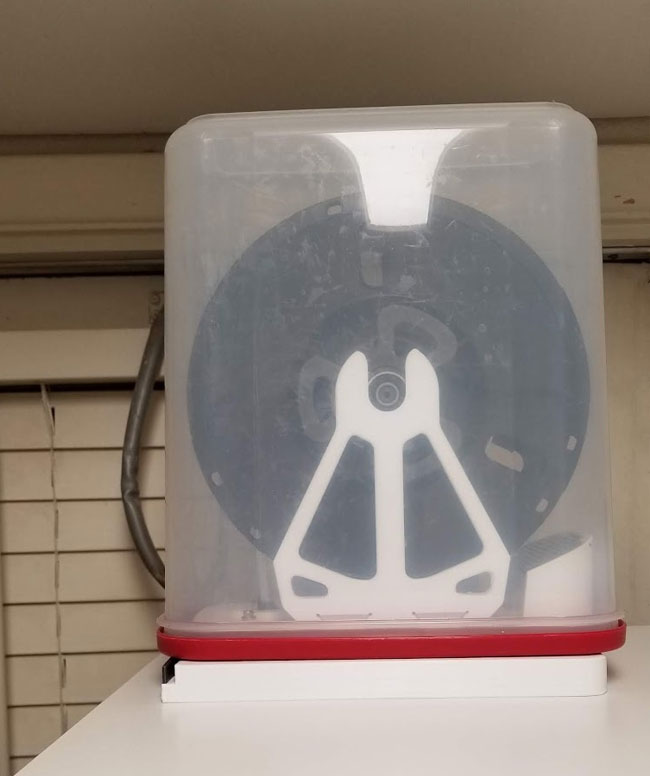

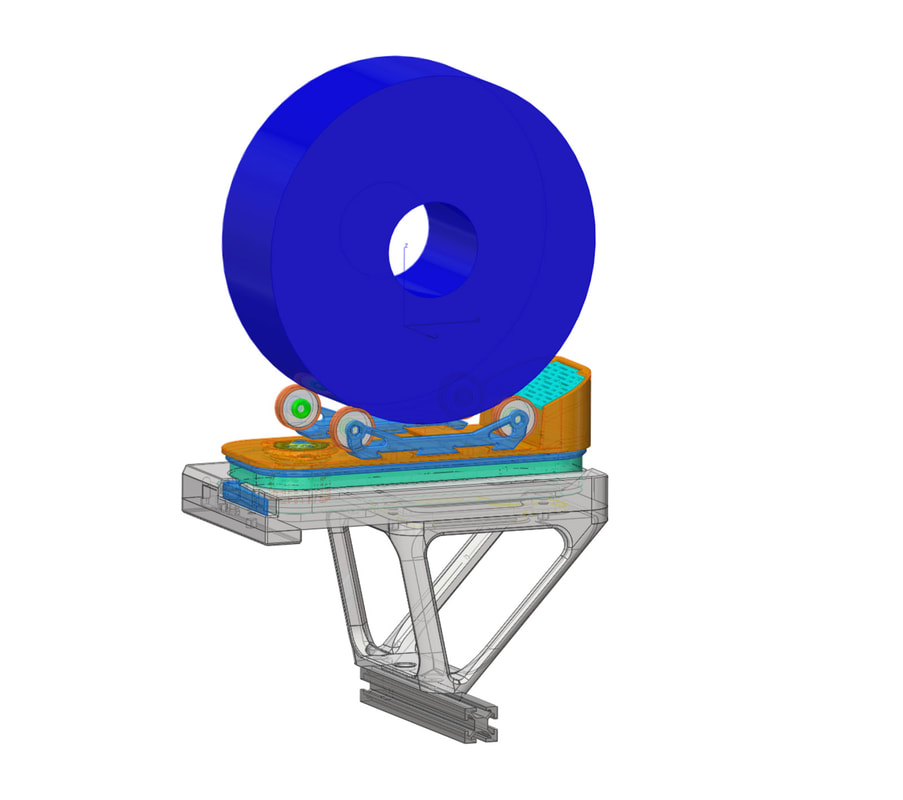

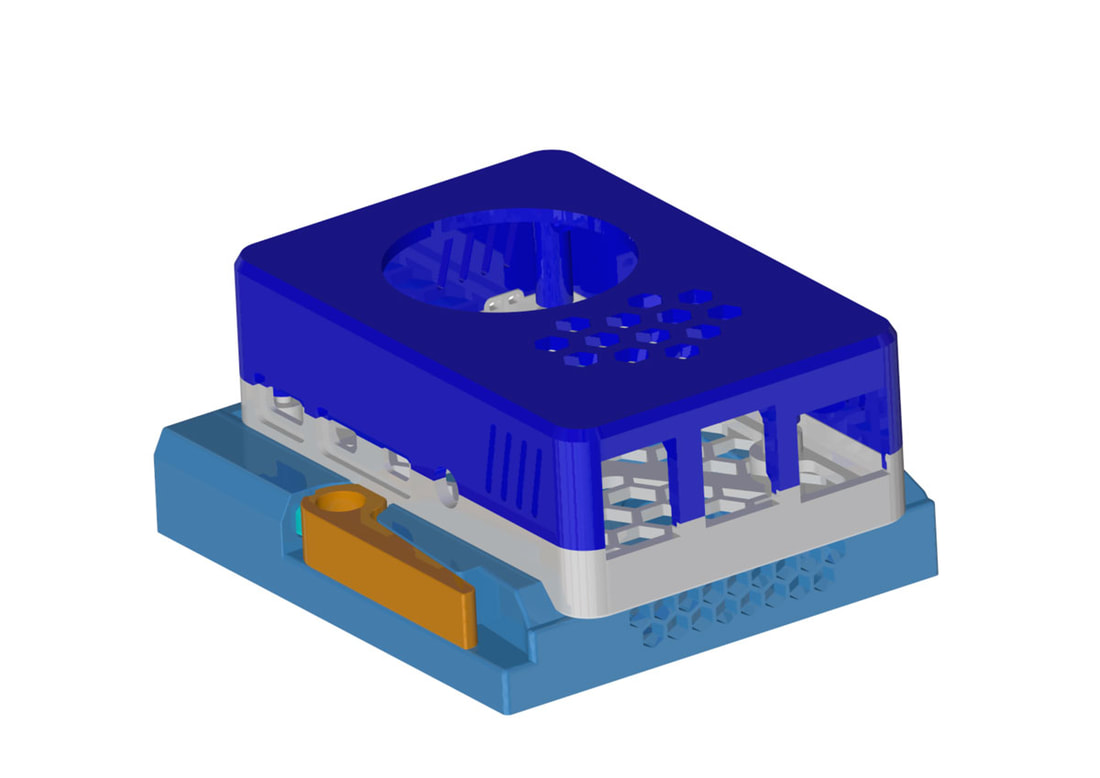

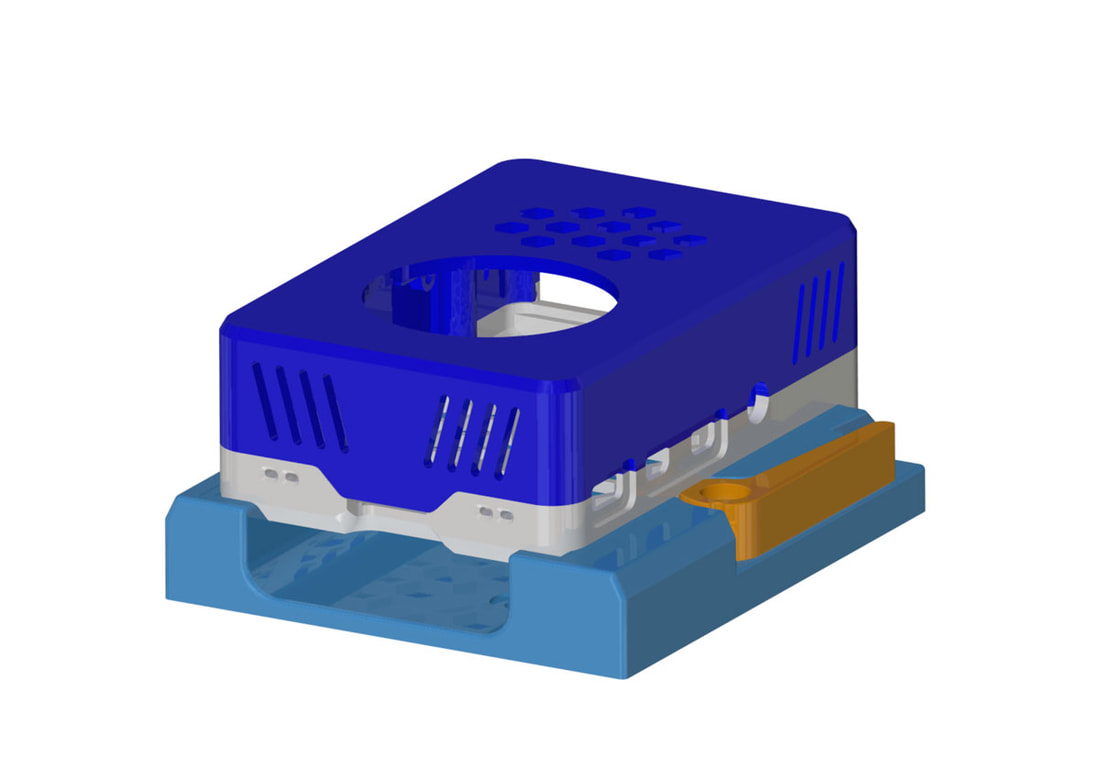

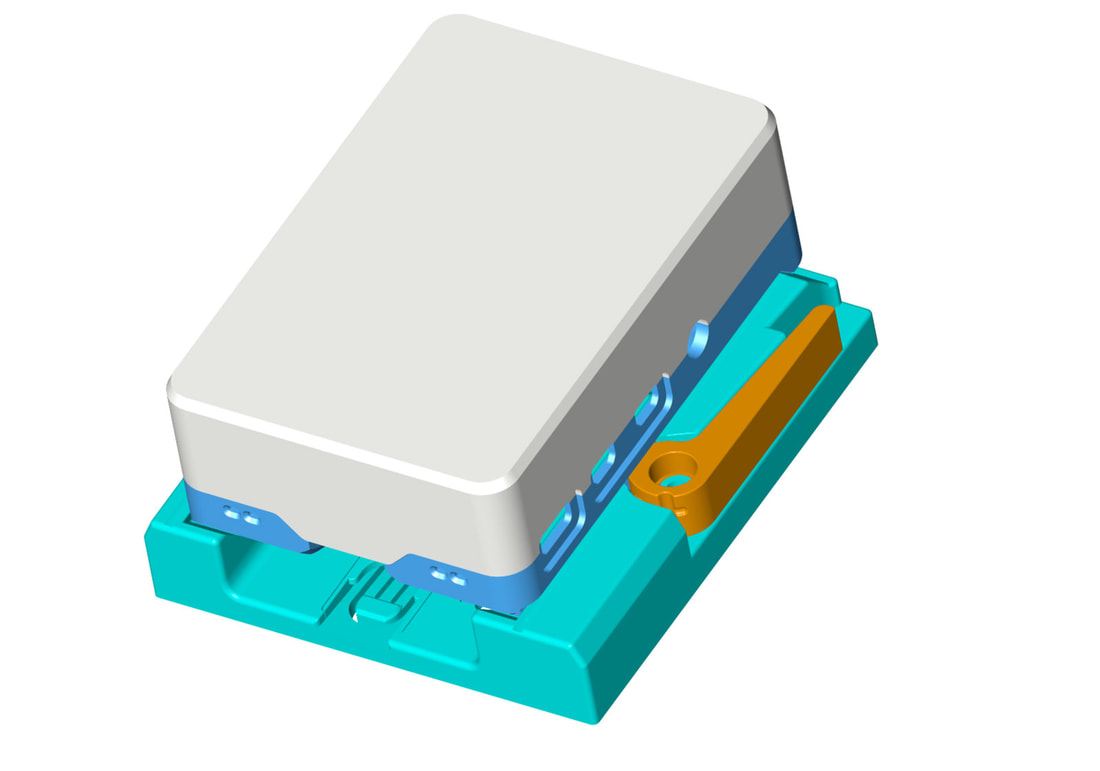

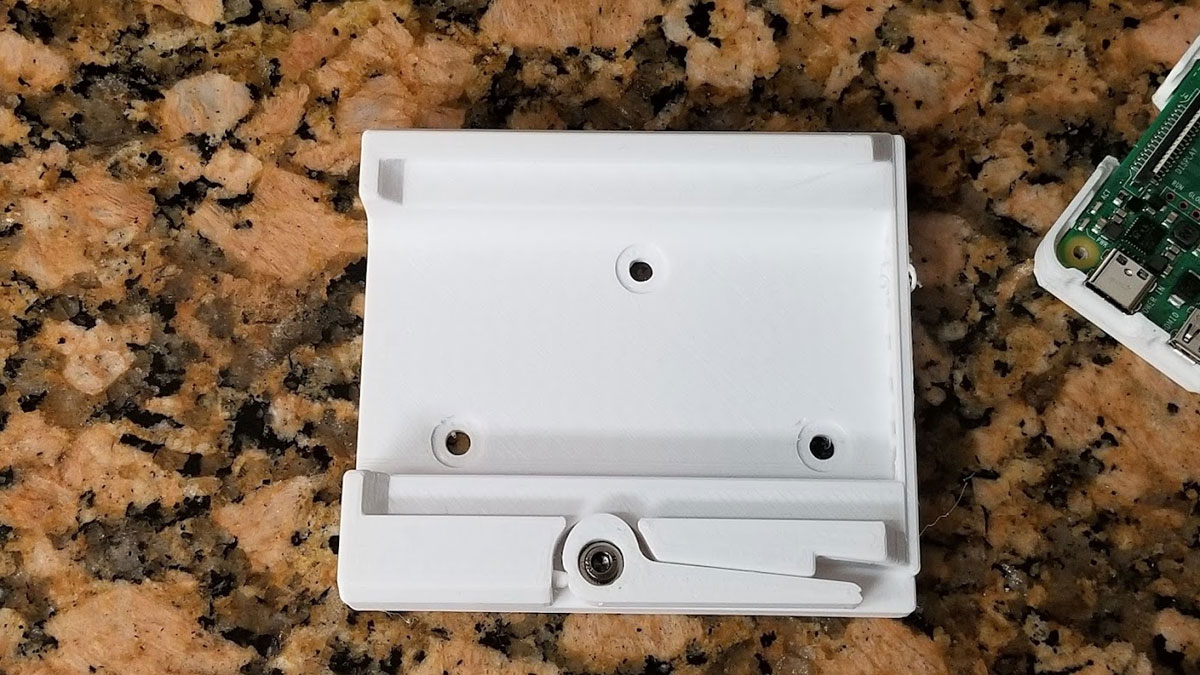

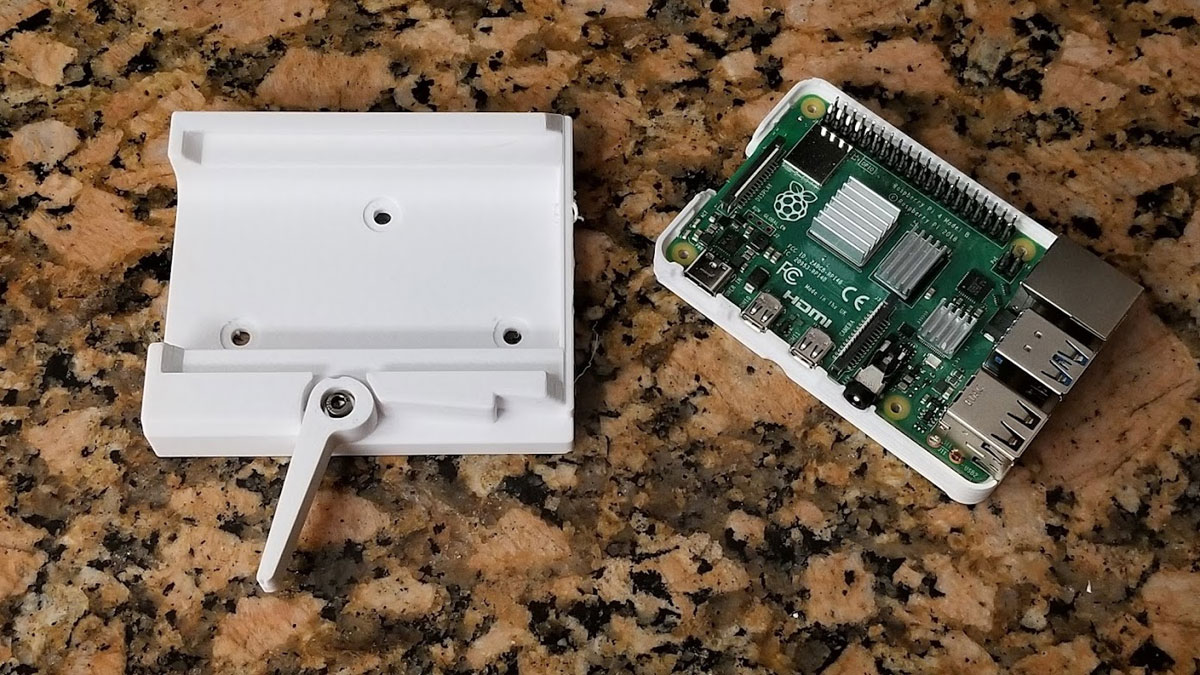

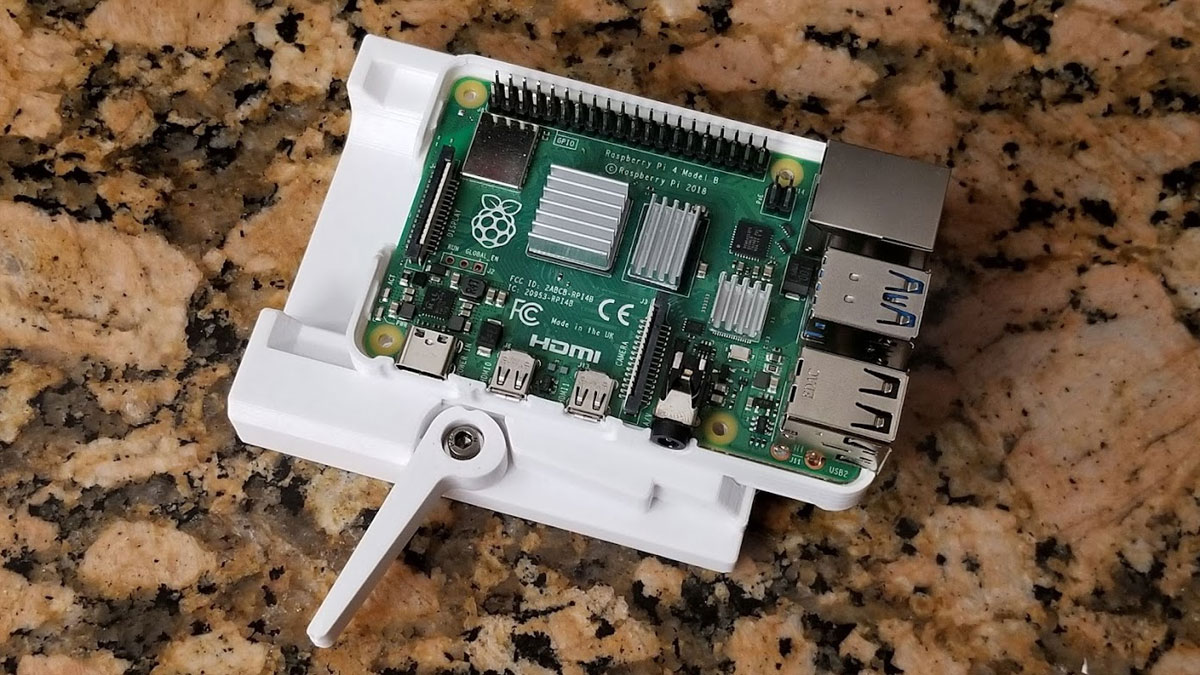

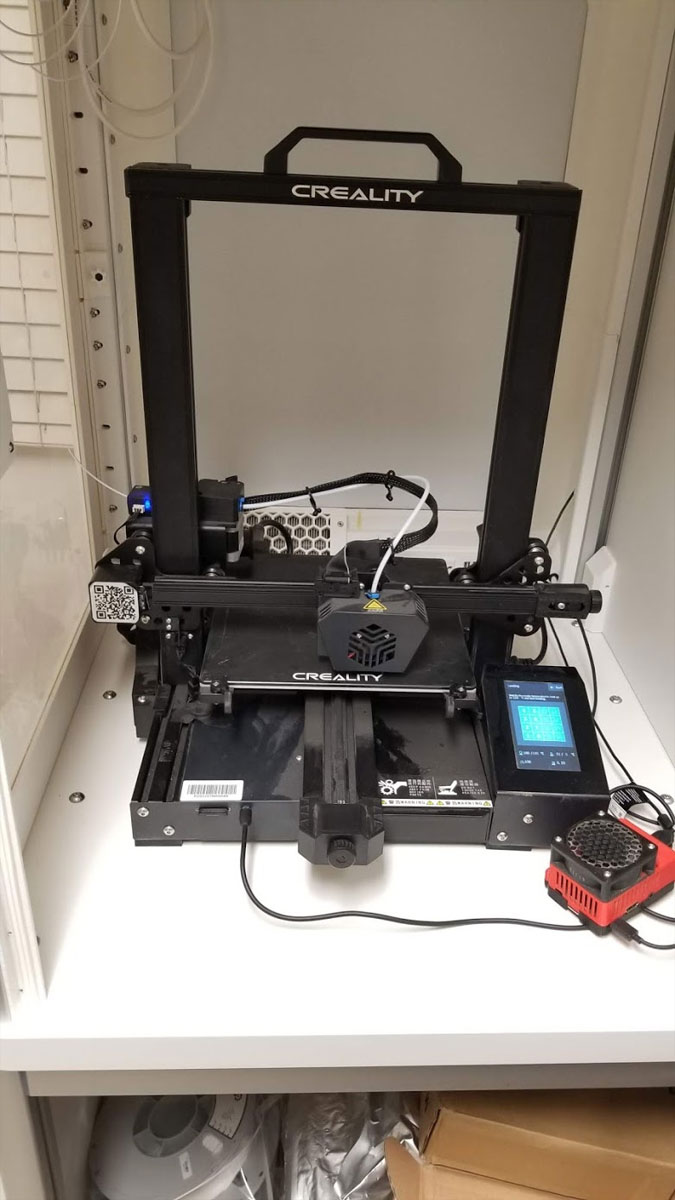

I uploaded some new pics of the completed design. Pardon the poor print quality on some of them, it is partly due to a worn 0.6mm nozzle (now swapped) and mostly due to the problem this holder is meant to solve - which was too much tension in the filament path. Prior to this the filament had to make two 90° turns to get to the extruder, now it only makes one and there is no tension in the filament prior to the extruder. I have yet to print the TPU gasket but plan to do that tomorrow, and will see if I can mount this to the top frame of my ender3 as well.

Update 4 - 9/10/2021: As usual I can't keep messing with the design. But since I printed and used it, I noted two things and thought of one more thing that could be improved:

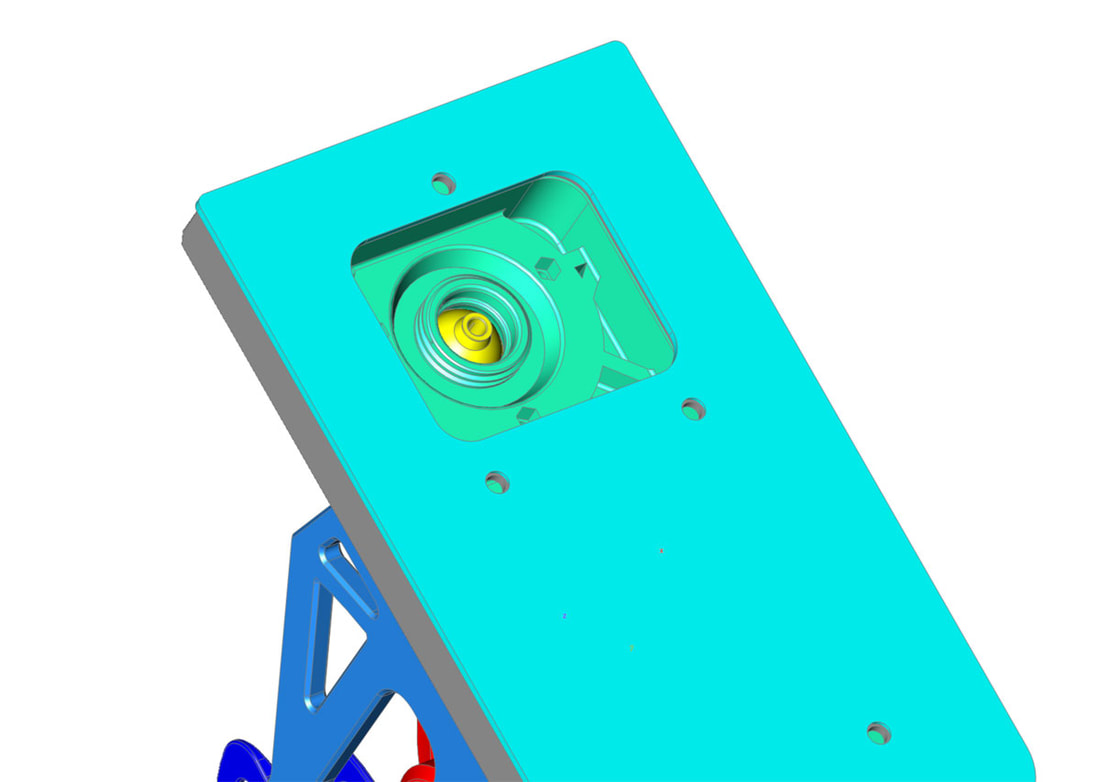

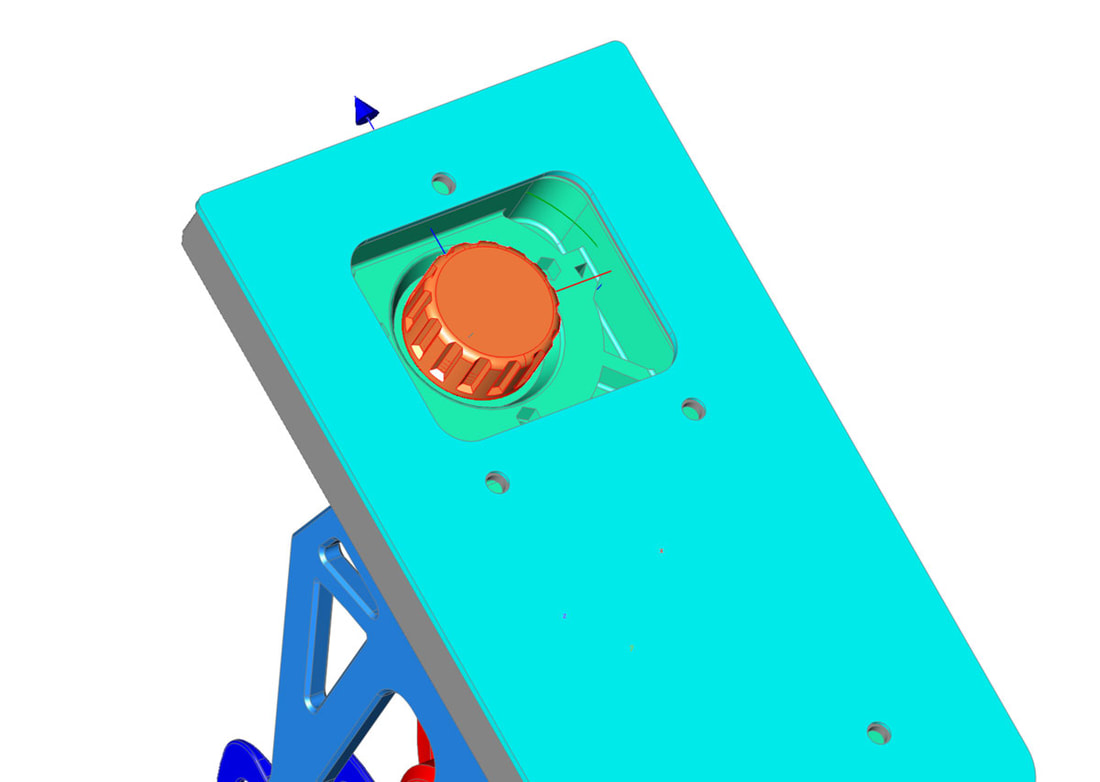

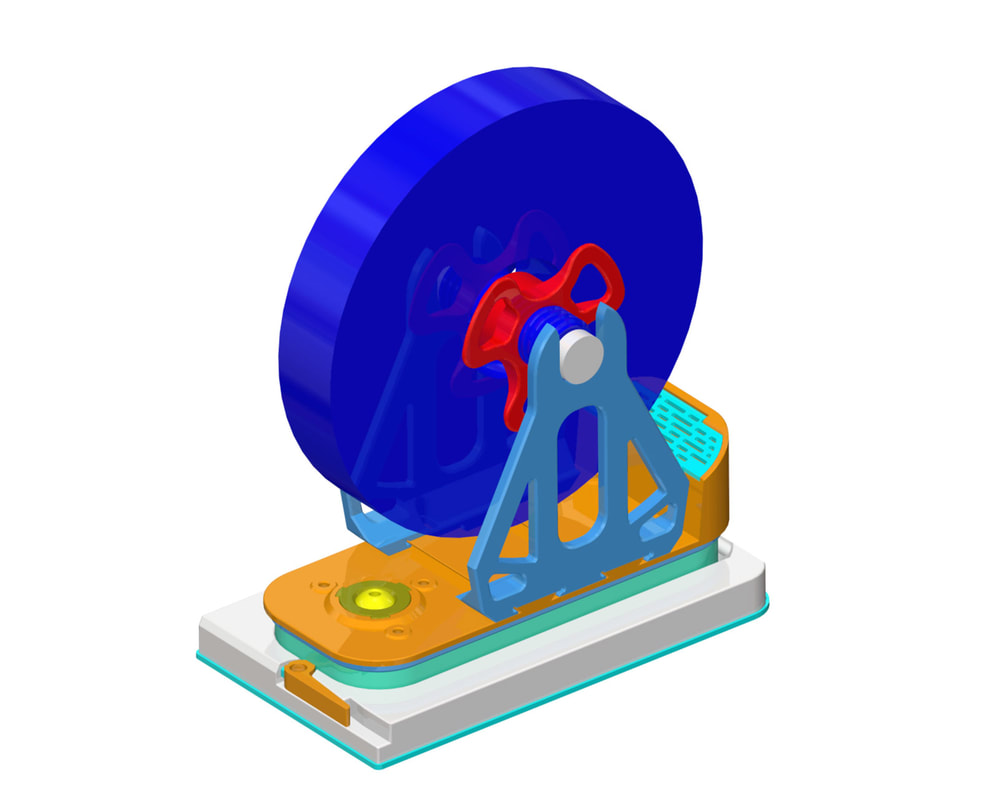

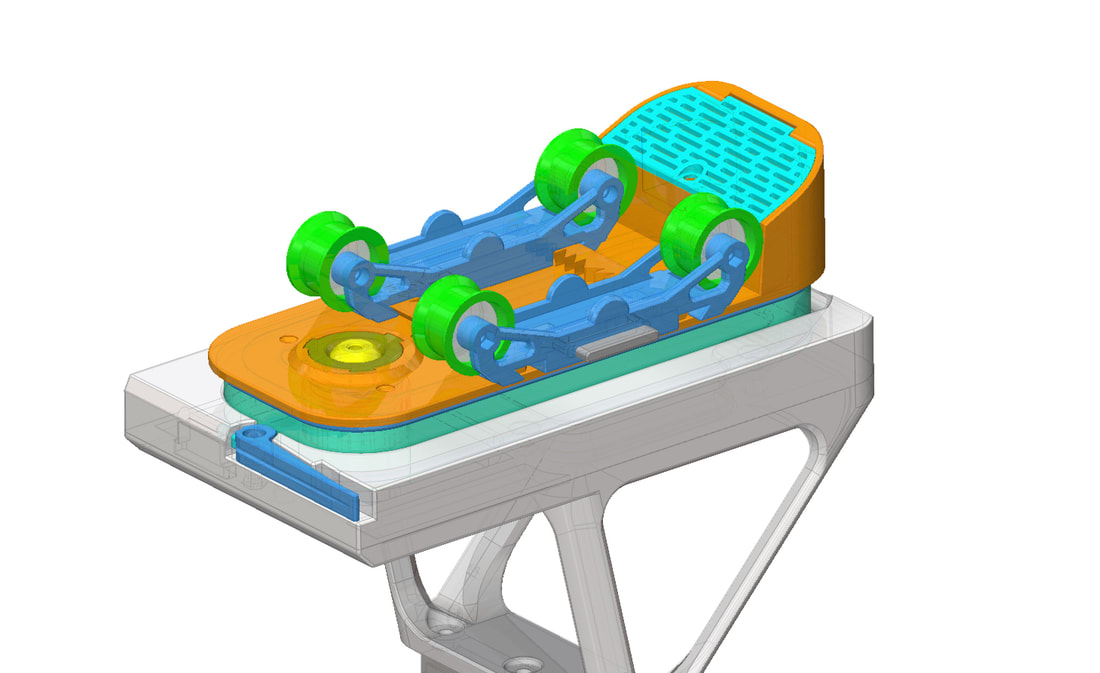

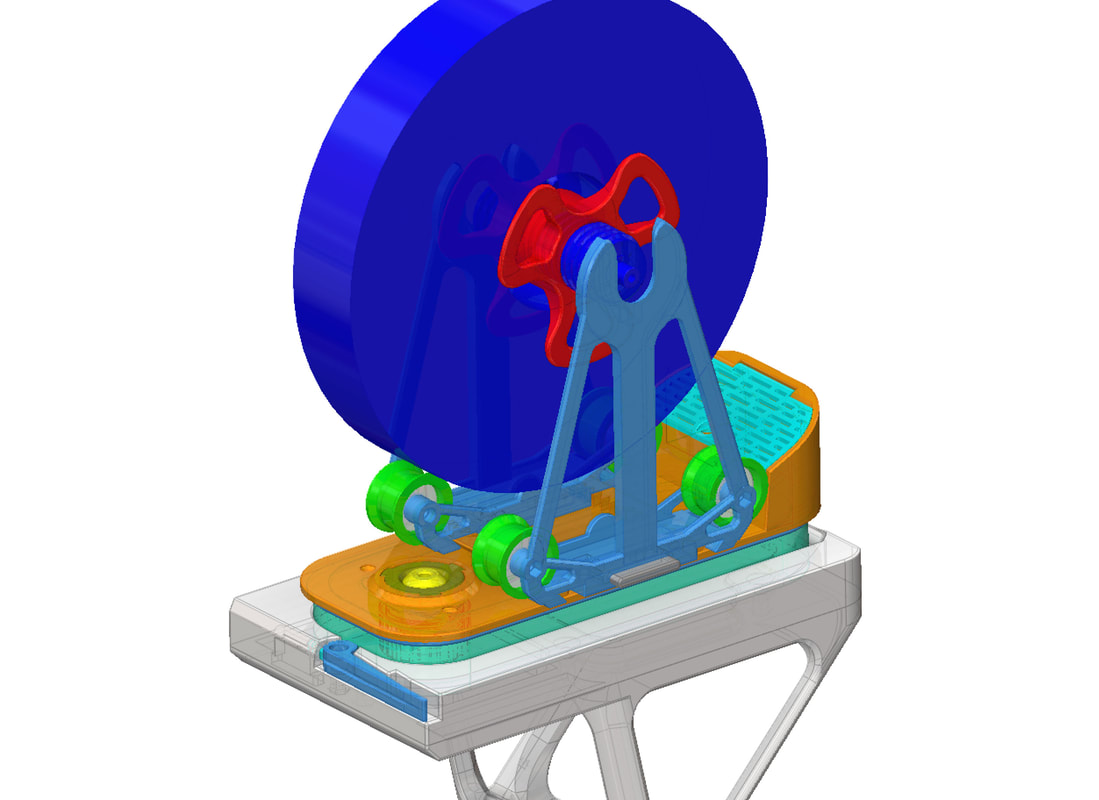

- The center axis spool holder has too little friction for some materials like TPU which wanted to come unspooled when I used it with this. So I re-worked it into a roller like the original model has, but this prints with one side and has some caps which hold the bearings on.

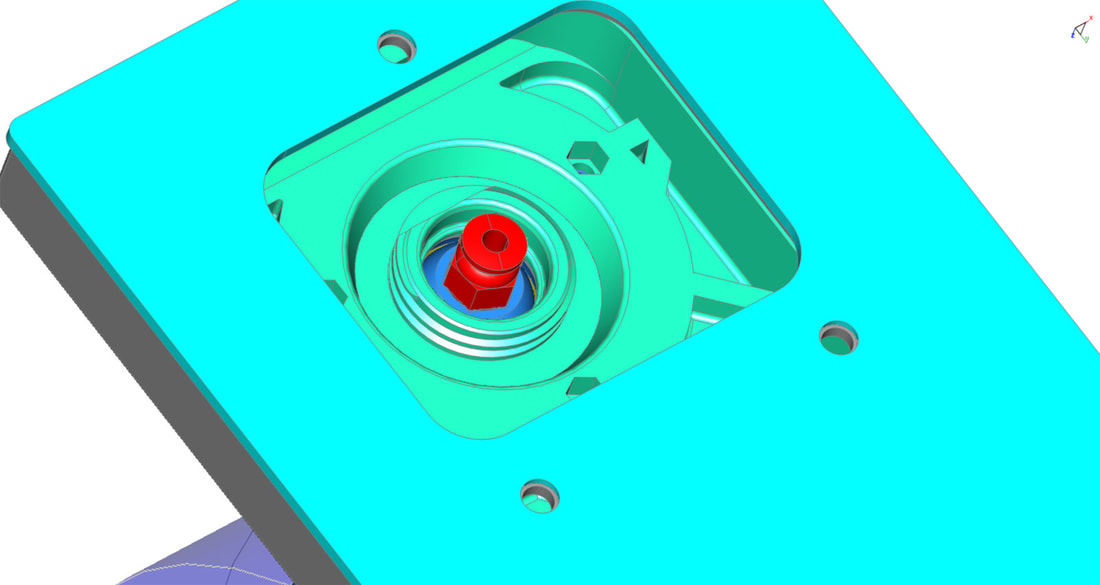

- The desiccant compartment needed a way to be closed more or less securely. I don't use the loose pellets in mine (I use the pouches), but for anyone who does, it would be frustrating to have them spill. I fixed that by adding a way to hold the lid down with a screw.

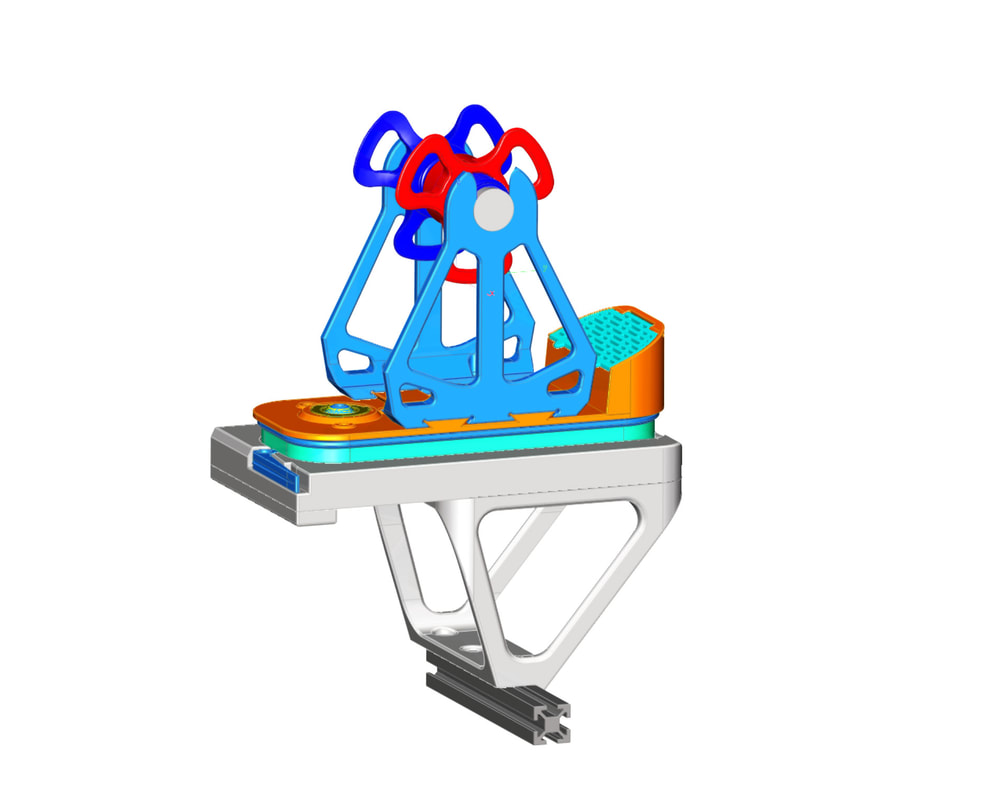

- Probably not a big deal but the center of mass of the spool is now over the 2020 rail on the "top mount" version which is designed to be mounted above printers that have 2020 rails. This version will also have a wire conduit to route a wire to the area below the spool holder since that seems like a nice place for a light, however I have no plans to develop that idea further since I cannot use this version on my printers.

Update 7 - 9/19/2021: Thingiverse seems to be having some problem since when I posted the design for the label roll holder (posted above), that thing did not make it into my designs on Thingiverse. So I can only find that thing when I go to it directly, but I don't find it using search or in my designs. So the design exists on Thingiverse but nobody can find it unless they go to the design directly, and that sucks. That's pretty much the way it is with Thingiverse, but I'm gonna wait till they get that problem fixed before I post this spool holder system, since I would guess the only way to "fix" it would be to delete the thing and re-post it.

The design is now uploaded to Printables here:

https://www.printables.com/model/79719

RSS Feed

RSS Feed