I did not even mention the latest problem today, which burned up an hour and got me thinking about all of the above prior issues - and the possibility that the machine may be either self aware or possessed. I did not have a vat of molten metal, and could not find an old priest and a young priest on short notice, so I had to start taking things apart to investigate myself. Let me back up, I just installed some PEI build surface today due to many issues with PLA curling on the glass (tried hairspray, purple glue stick and cursing, nothing worked). Since the build surface was a it wee bit thicker I had to re-level it. Here is where it started acting very odd. After installing the level sensor, the first part of the process is to home, but it went to the home position and just grinded away up there as though it was trying to sense the bed. Multiple re-sets later and no improvements, but other weirdness led me to think either one of my limit switches or the z-probe was faulty of not connected.

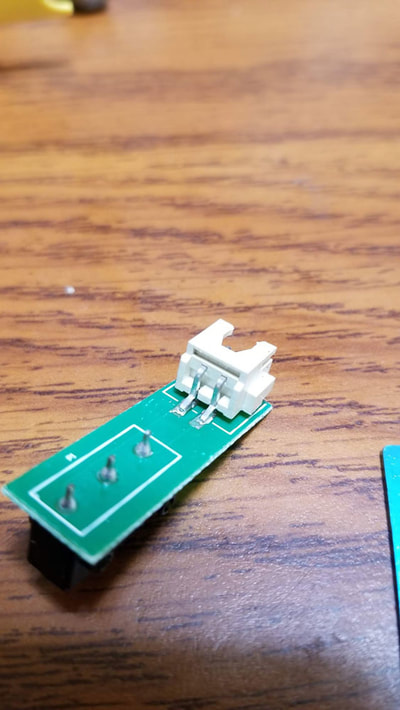

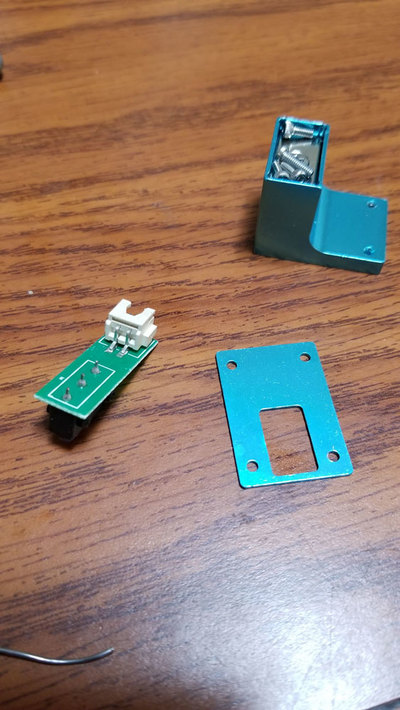

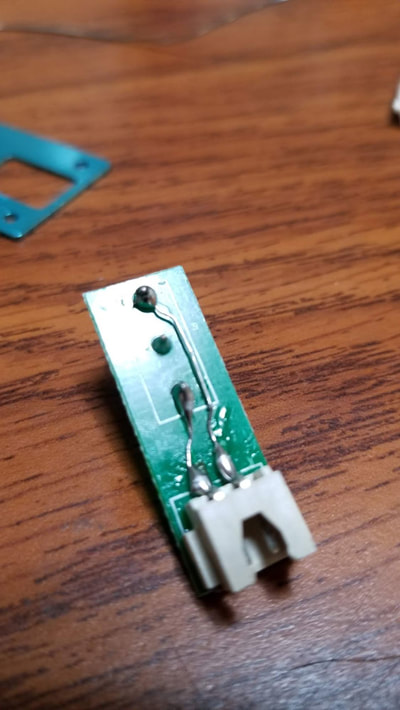

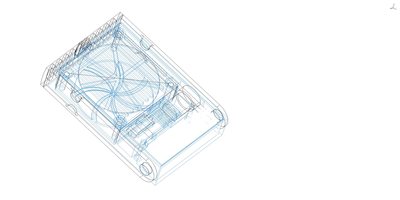

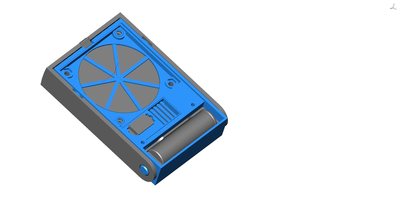

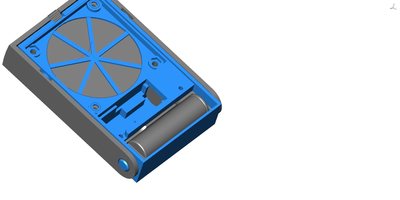

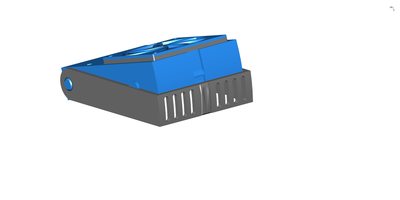

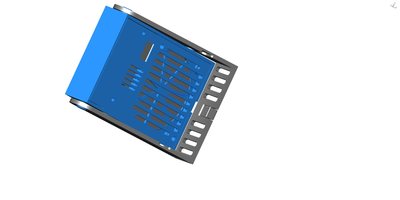

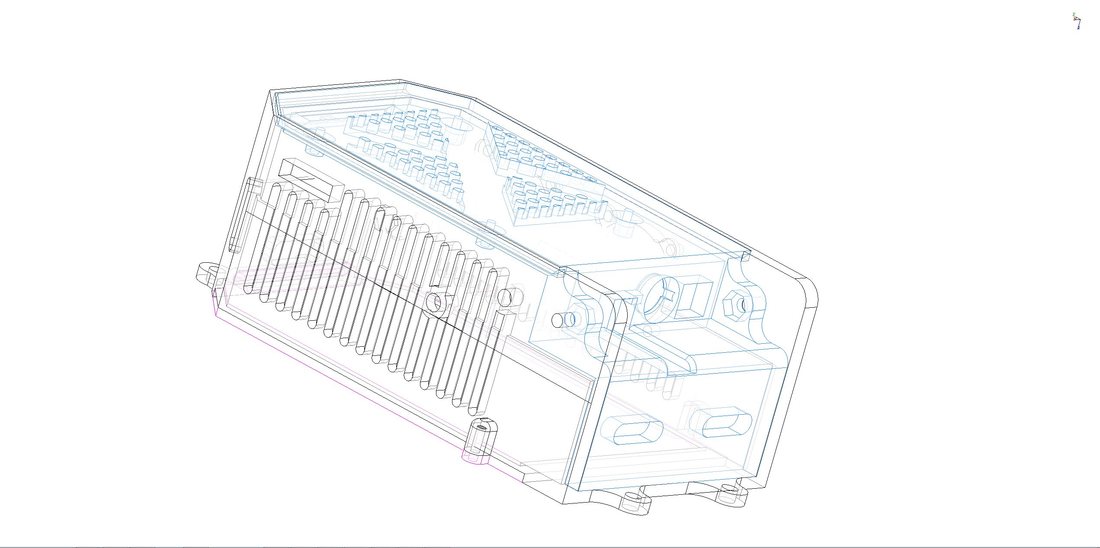

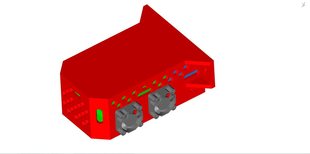

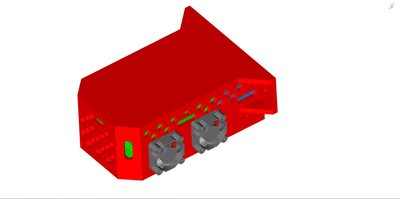

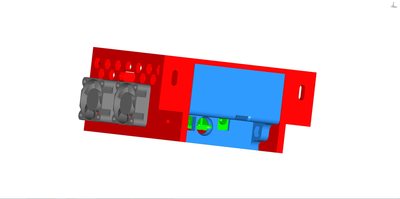

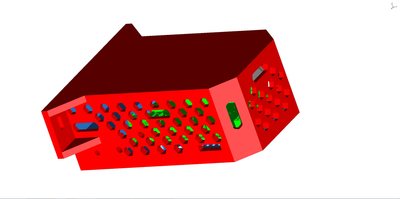

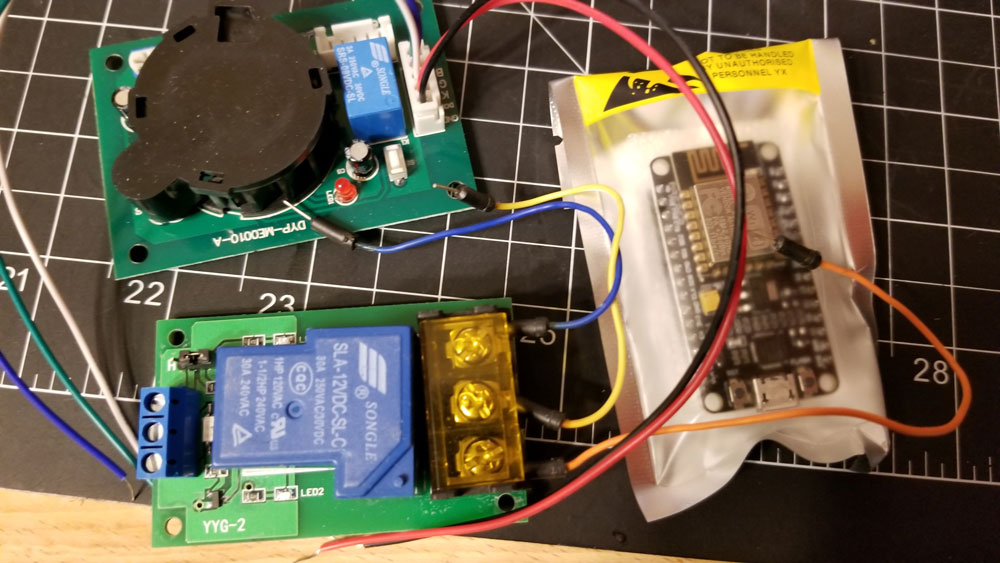

I broke out the meter and tested each switch, X, Y and Z limits are good, but the Z-probe was not. For the record the limits are all NO (normally open) which is good since if they fail the board will lose the signal on them and hopefully keep the head from doing damage. I took the z-probe apart and found that the connector had cracked at solder joint that holds it to the board. The connector is surface mounted (not though hole) and there is a small gap as well below the connector - so all the torque on the connector is relayed to the surface mount pads on the board - which is poor design IMHO. I added some gorilla glue below the connector to fill the small gap and provide some mechanical bond between the connector and board, then (since the there was no longer continuity between the connectors' pads and the switch terminals I had to solder some wires (actually used some wires cut off resistors), and then covered the exposed wires with some more glue to insulate them. After that I re-tested the switch and it worked, however I forgot to plug it back in which led to a minute of head scratching before the light bulb went off (dimly) and I was able to get the auto-leveling working again. For reference here are some pics of the inside of the z-probe.

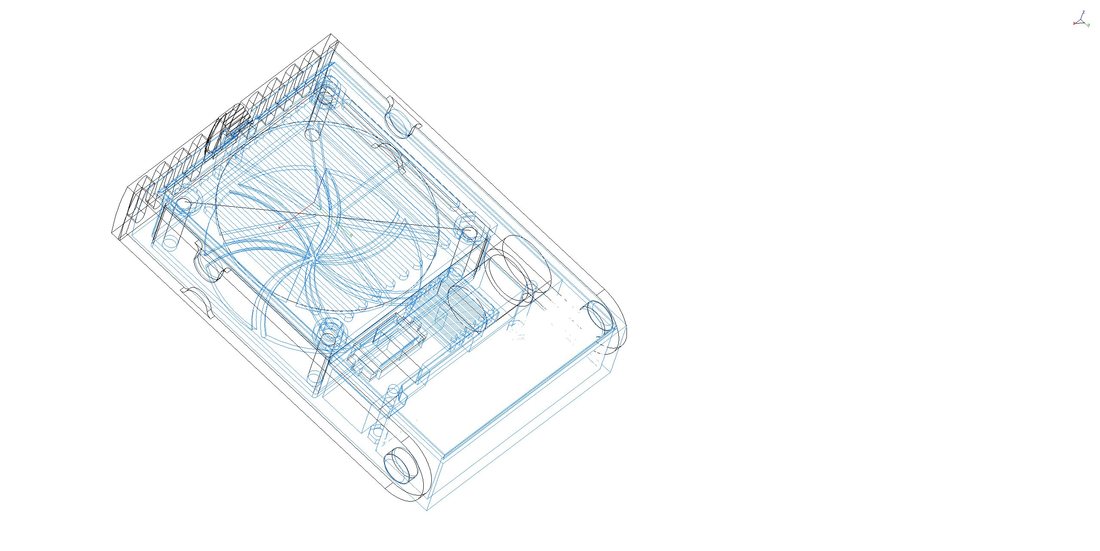

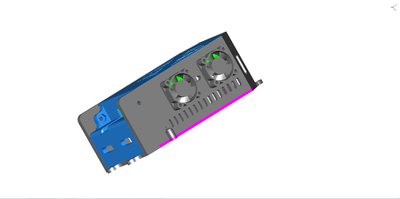

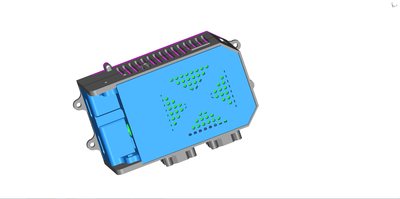

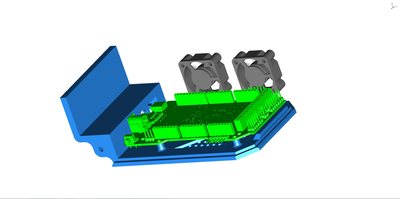

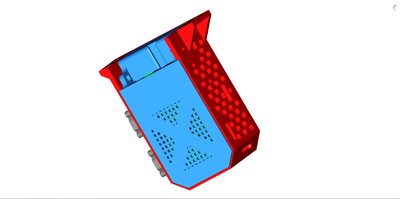

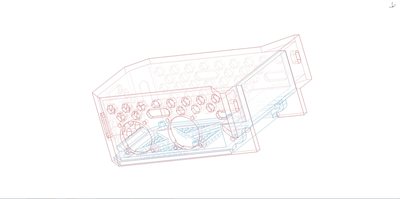

Update 10/19/2018 - The Anycubic Kossel is now printing like a champ. A couple things that may have attributed to the layer shifts were the board (which is now swapped with a Re-ARM + RAMPS 1.6 running Marlin 2.0), and some new clamps I installed on the heated bed. The new clamps are an improvement on the prior design, and tightly hold the bed from the sides and the top which should remove any possible shifting due to the bed clamps.

RSS Feed

RSS Feed