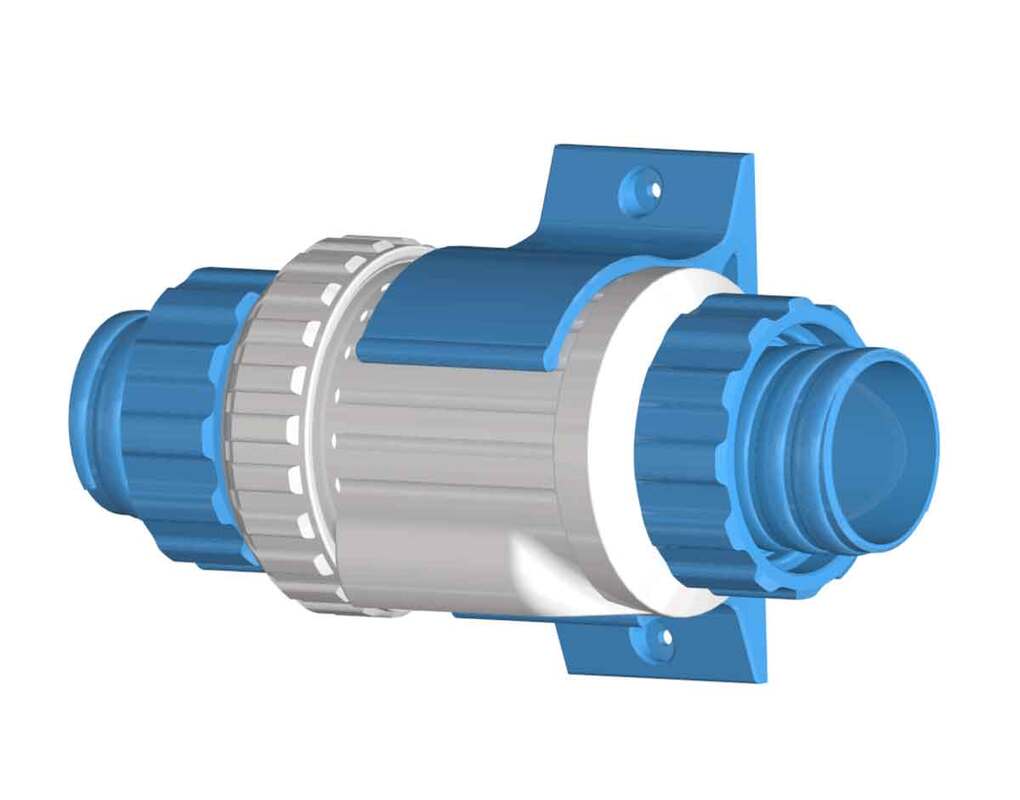

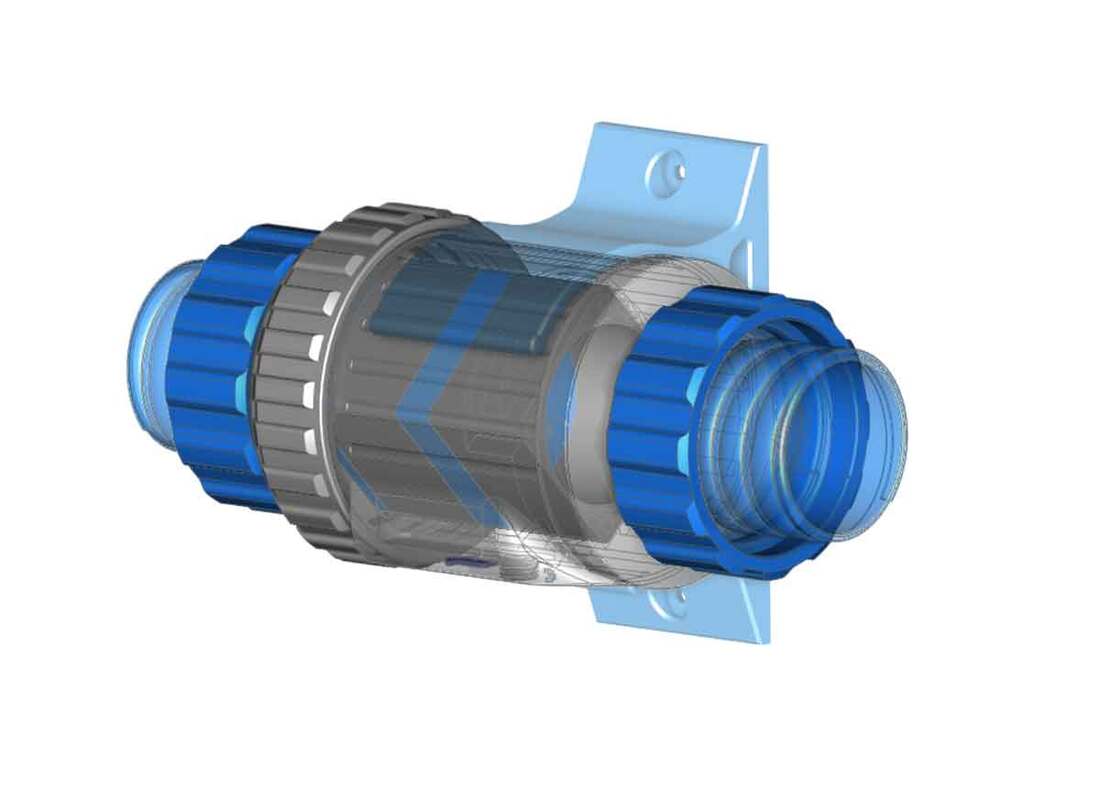

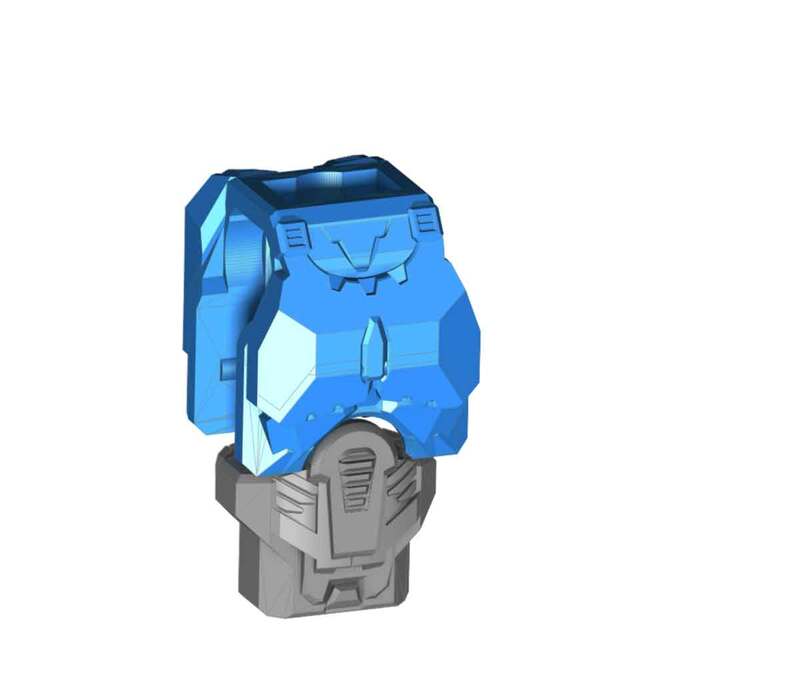

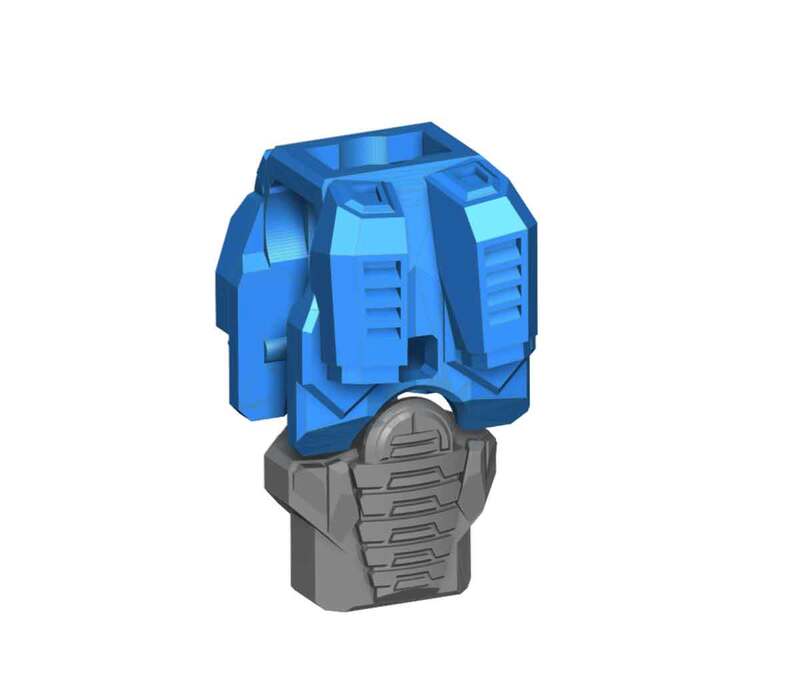

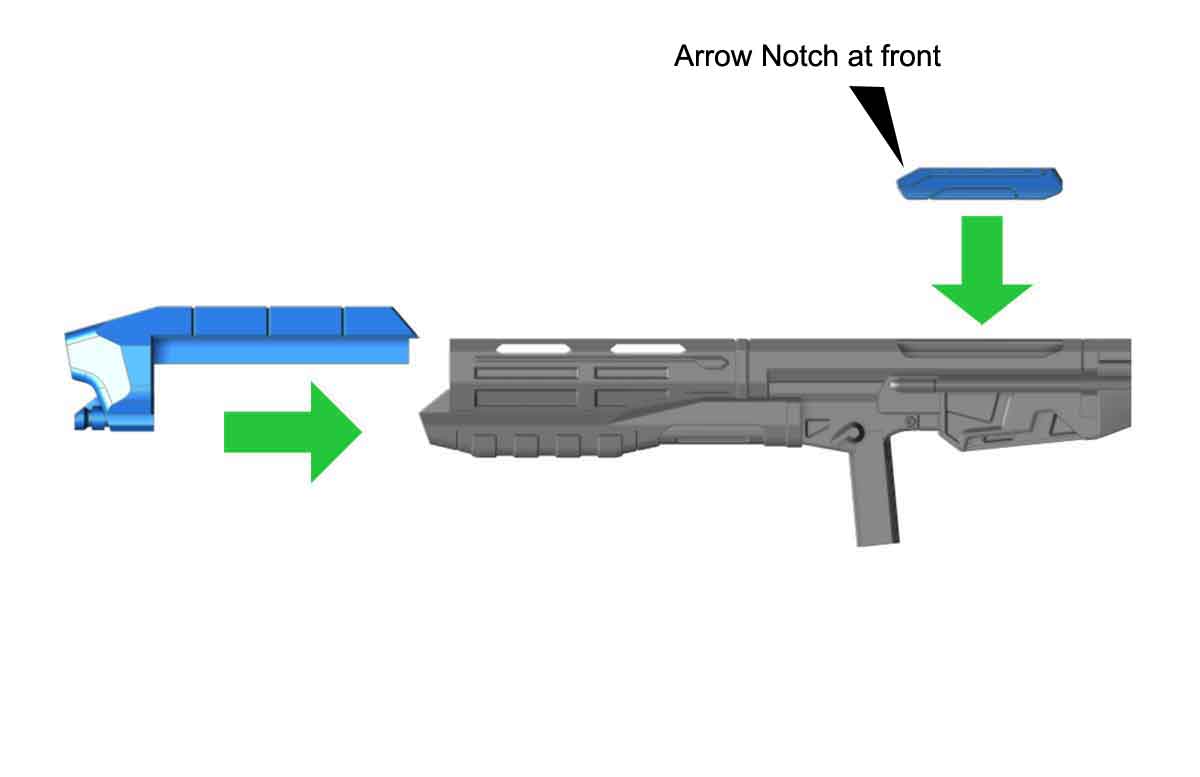

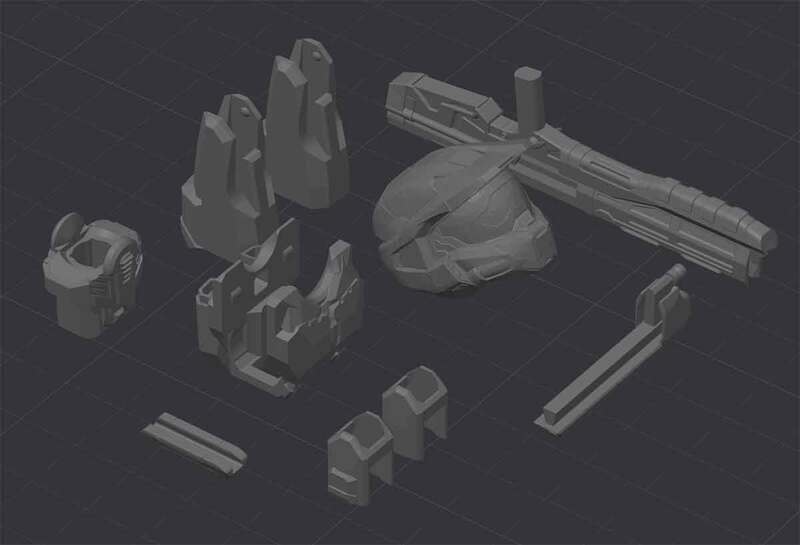

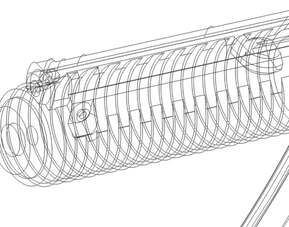

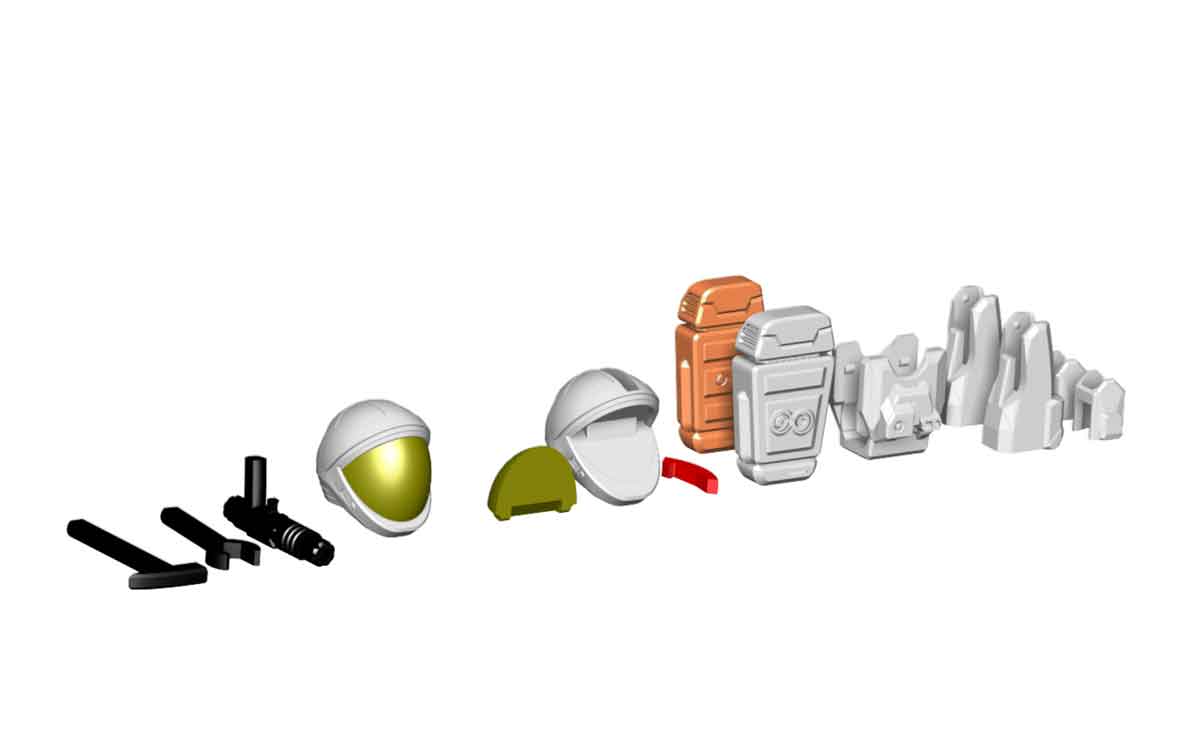

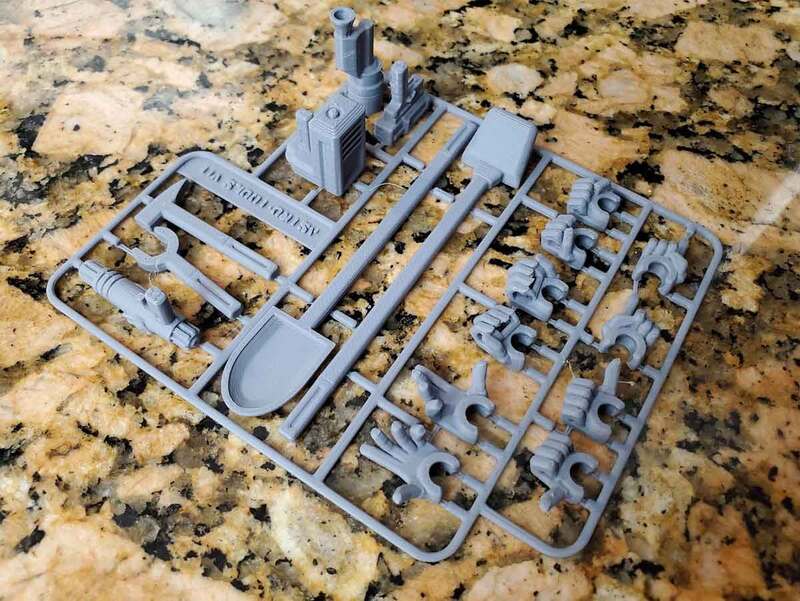

To mitigate the problems, I run my X1C in an enclosure (which is intended for a different printer), and duct that enclosure outside though a HEPA filter. I also run my bento box clone in the X1C's stock enclosure, which acts as a first stage. This setup has been working well, with no smells getting into the house. My longer term solution however, is to remove the X1C from the enclosure, and use a booster fan to suck the air from the back of the X1C, then duct it outside. The booster fan project has been on the back burner though for a few months, and although it worked, I felt like it may be possible to improve it a bit. The recent threads on Reddit, where some folks are struggling to to find ways to balance their health concerns with running a 3D printer indoors, got me thinking that I should get back to the project and test it on my printer. So today I spent a few hours redesigning the original single fan design, into a dual stacked fan design, which hopefully will boost the static pressure. Static pressure is what's needed when air needs to be pushed through a hose or a filter, and although one fan was able to do it, I think 2 fans may work better. The pics above show the new design, which uses two 6038 fans (4 wire PWM version) which will be run in parallel in a stacked setup. I'm burning up the last of a roll of PETG to make the body of it now, and should have something to test with soon.

For this idea to work though, I will need to mostly seal the enclosure, which will just require taping over the holes on the base of the printer, and sealing the door (which I have already done). There will be some places for air to get in, but I want to minimize them, so the ducted fan can have the best chance of creating a small negative pressure inside the stock enclosure. If this works and I can run the X1C outside the enclosure without smells getting loose, then I plan to post the design, but that is gonna take time as always.

RSS Feed

RSS Feed