https://makerworld.com/en/models/62636

https://www.printables.com/model/626897-bambu-labs-x1c-spare-parts-case-box-for-stuff

There is also a build guide here.

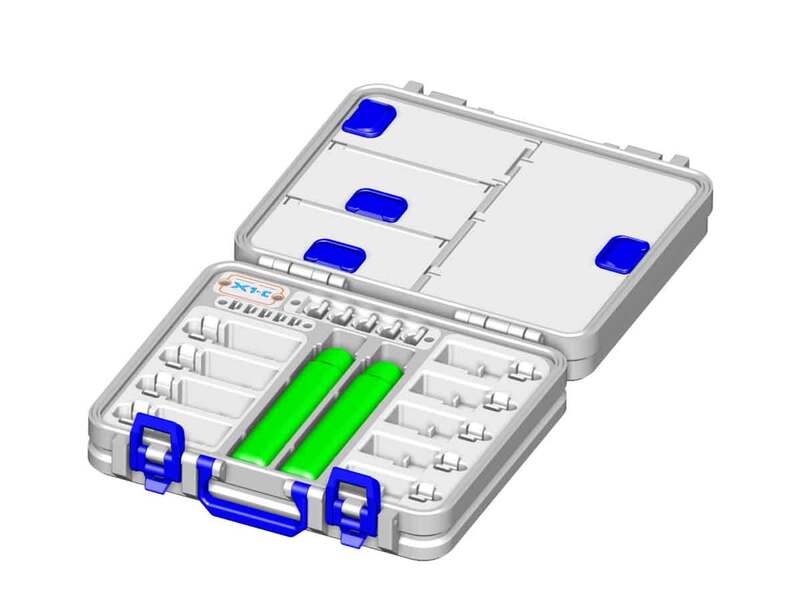

There is also a Gridfinity version of the case in the works, which will hold 15 units (9 Gridfinity "units" high or 9x7mm).

Both the cases will be completed after the filter design is posted, since the cases will take some time to print and test. But at least I don't need to wait on parts from China to get them done.

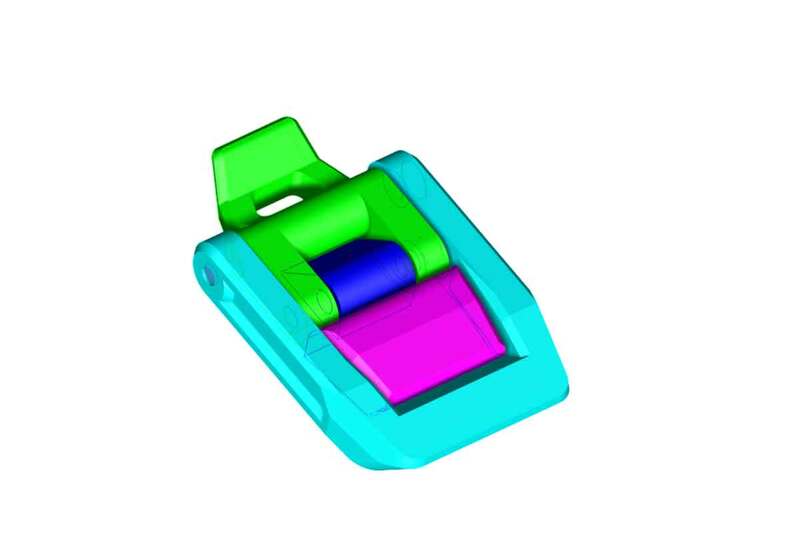

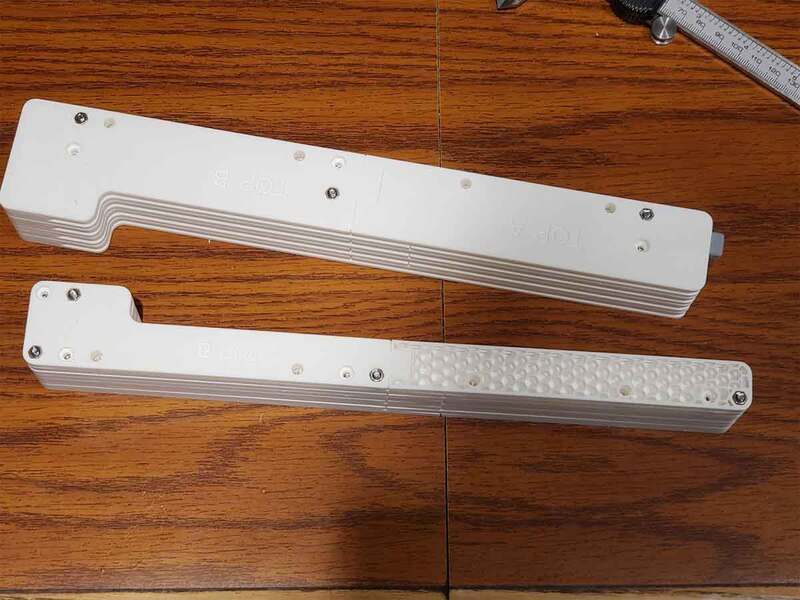

I spent way too long with these simple designs, and probably printed a dozen iterations of the wiper and cutter holder prototypes, before I had a design that I could be happy with. Now I just need to integrate them into the case design, and print those parts to test.

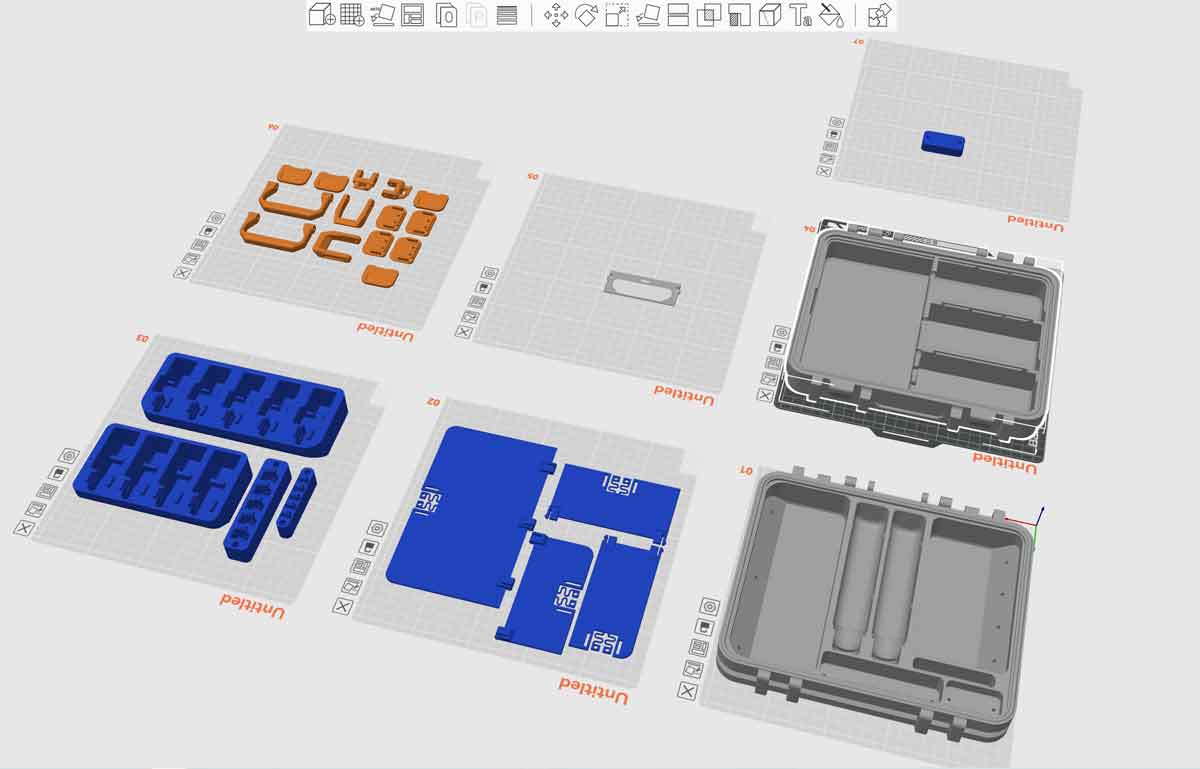

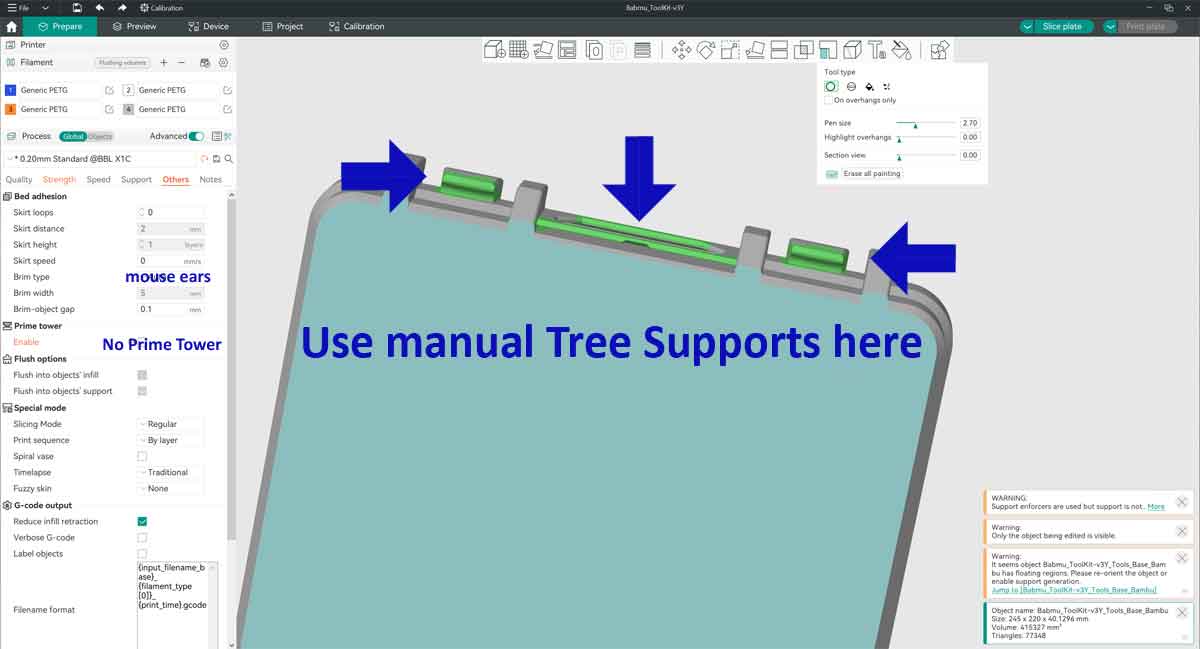

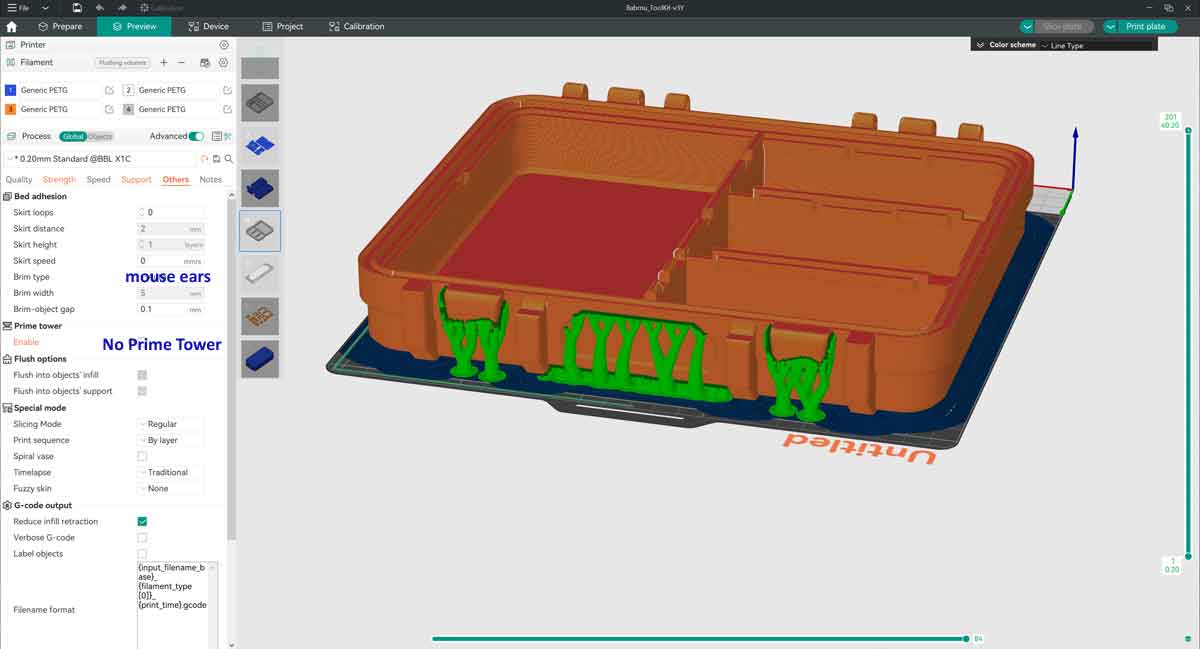

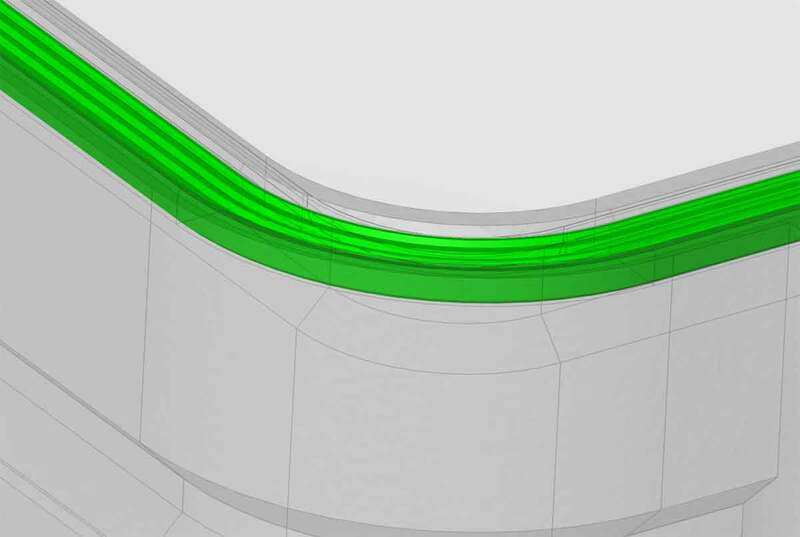

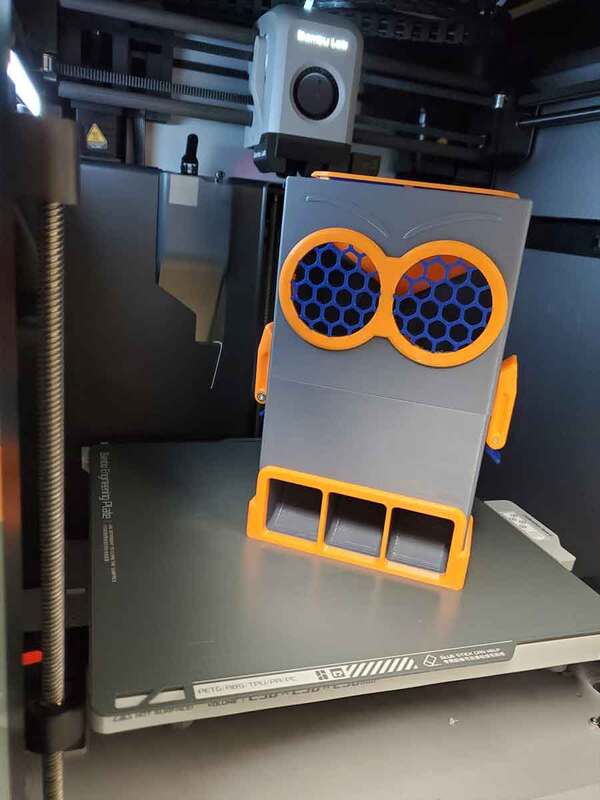

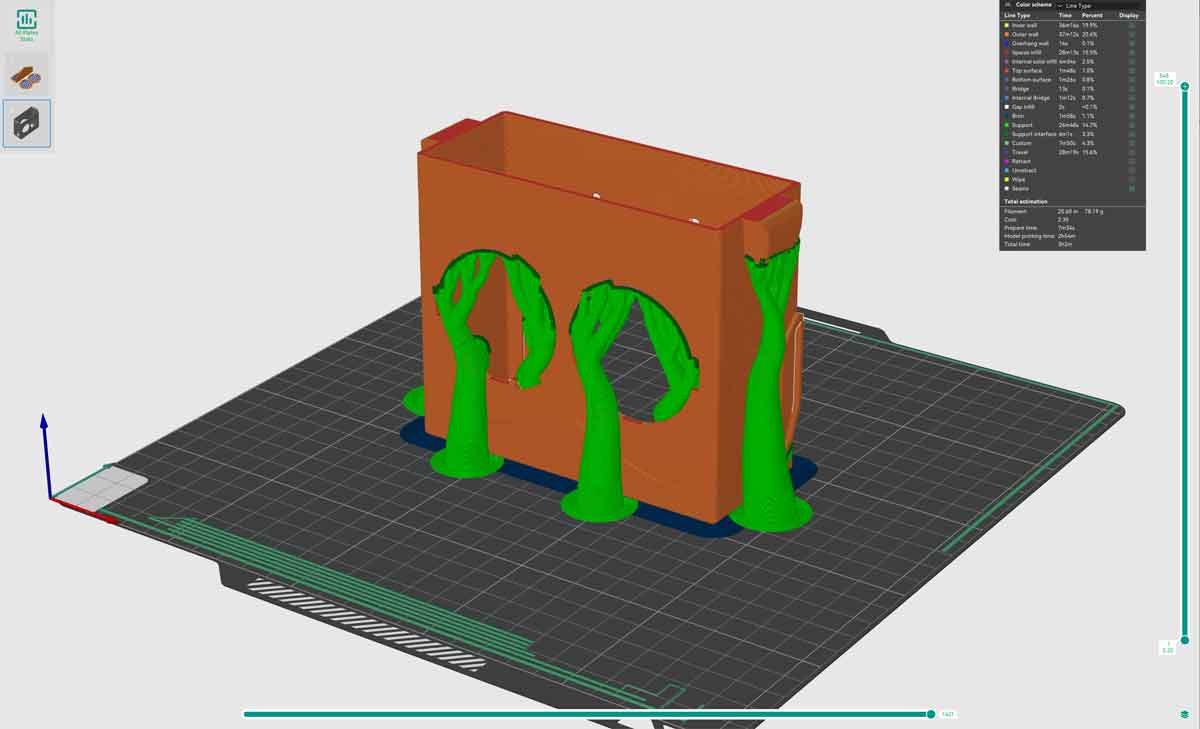

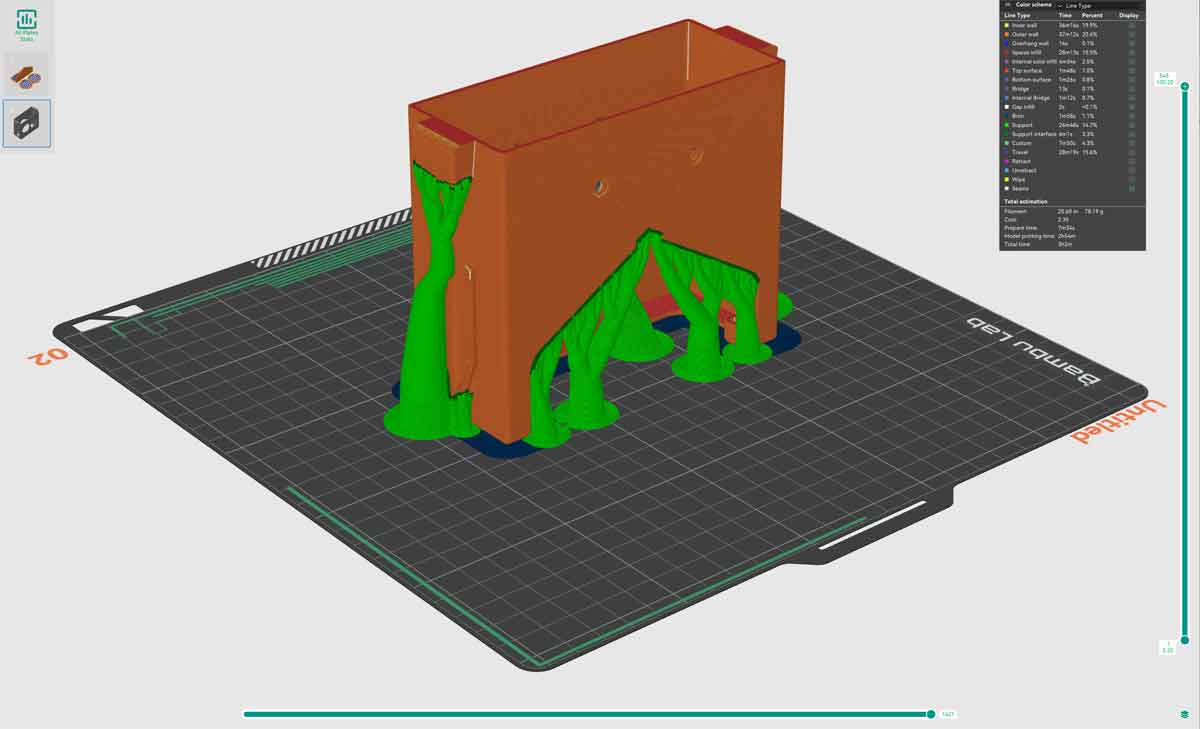

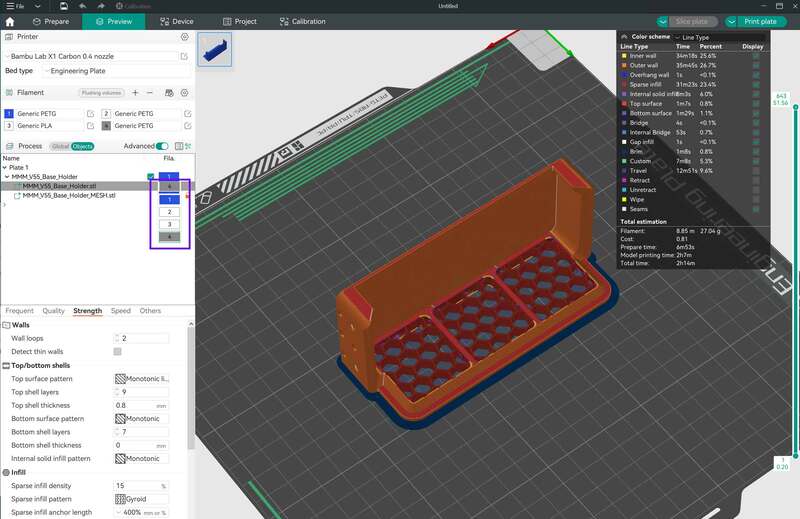

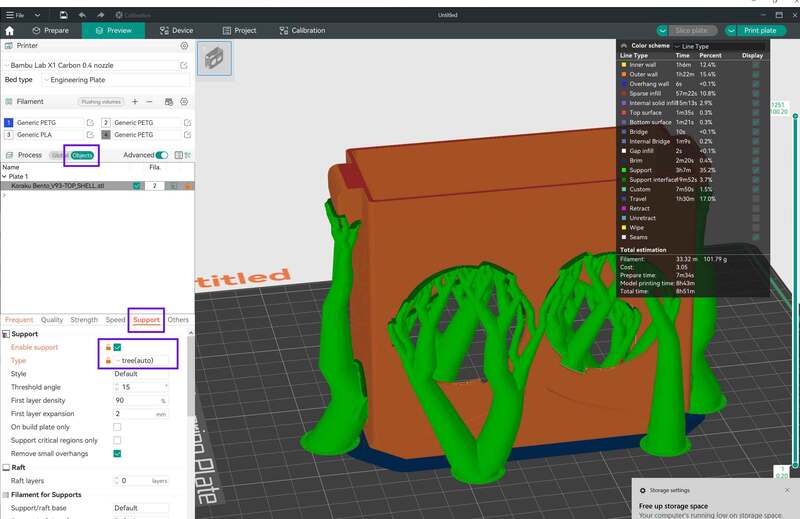

I'm currently running the top of the toolbox first (the part which will have the logo and compartments). I had to print the top using no prime tower, mouse ears only and manual supports along the front where there are some unsupported overhangs, Ideally the model would have no supports. However due to the way the draw latches work, some supports are required. There are also some supports in the area of the case label frame, which I think are unavoidable. I expect that I can print this in 5 almost full plates and 2 multicolor plates (split the multicolor prints to minimize the waste).

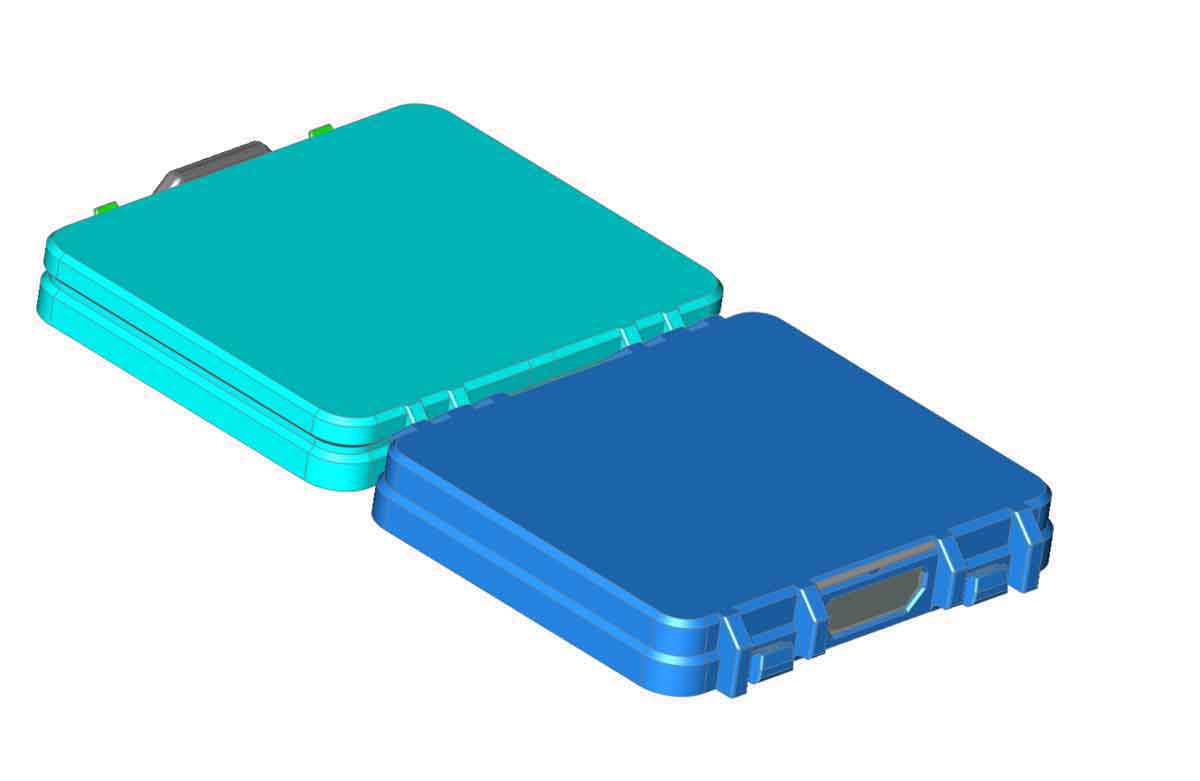

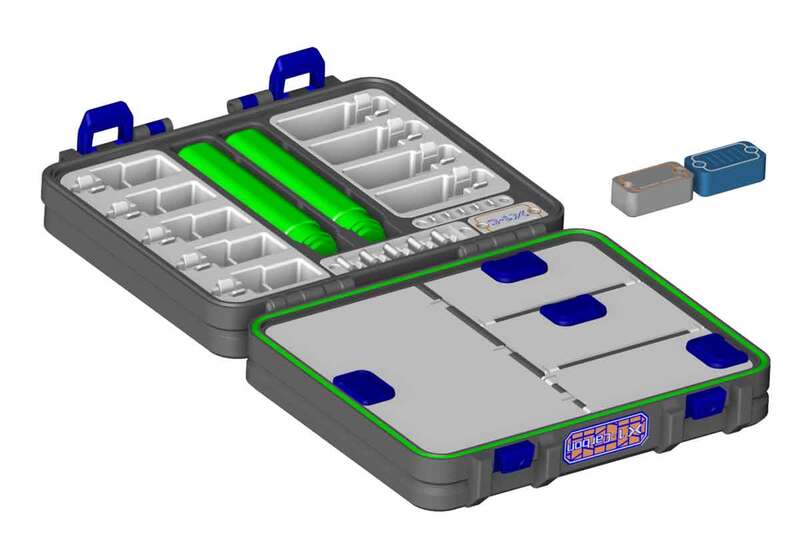

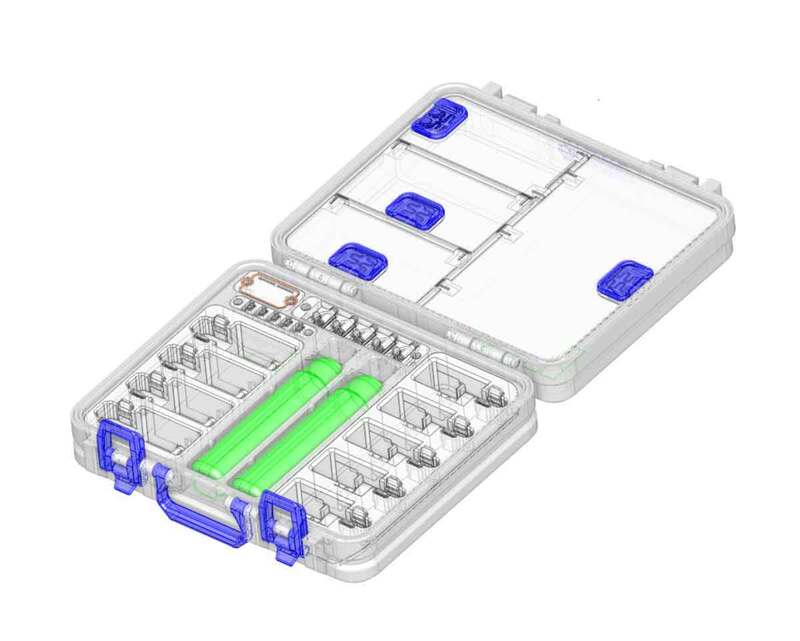

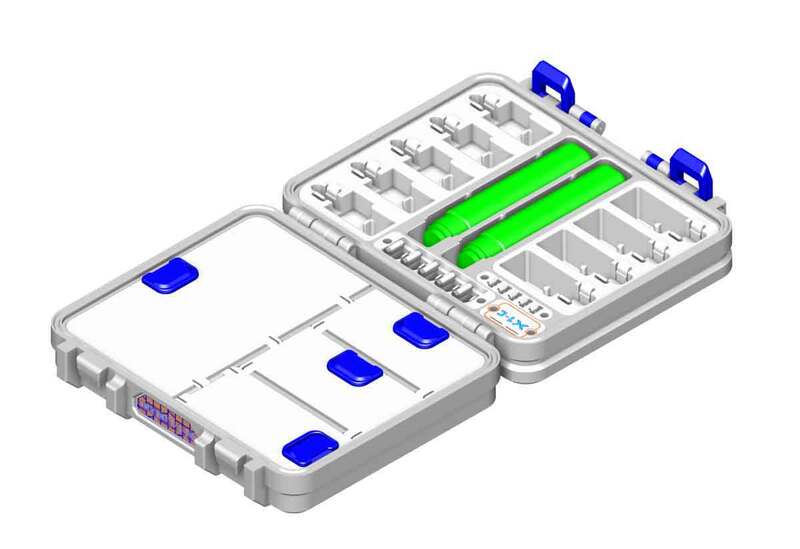

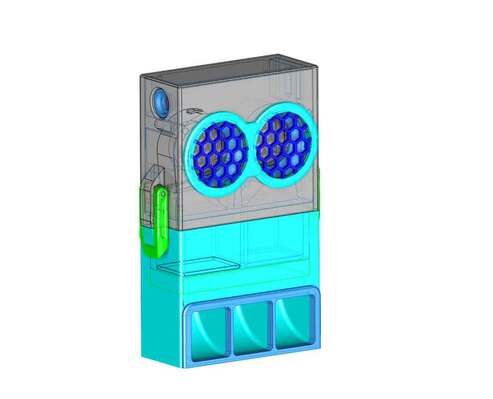

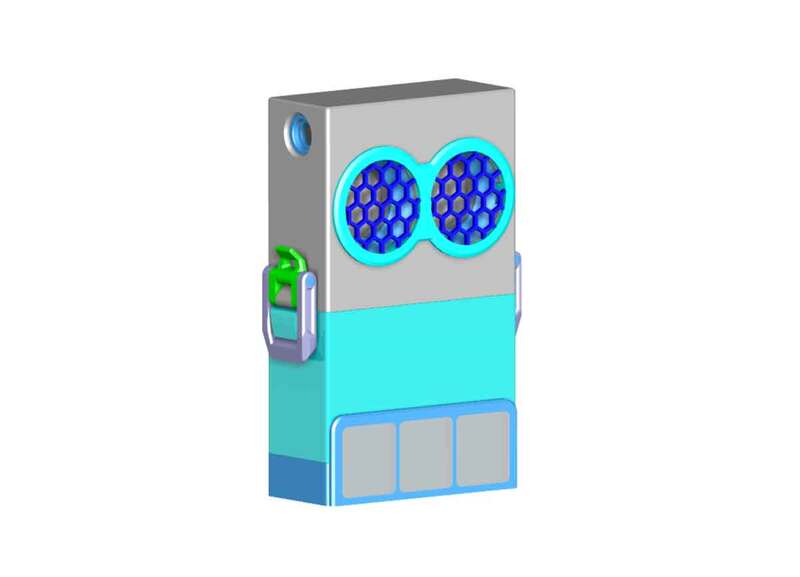

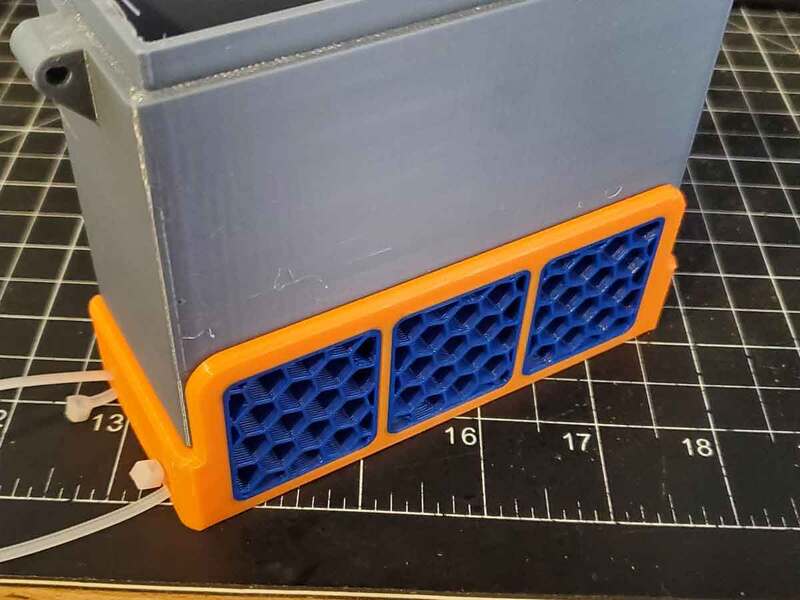

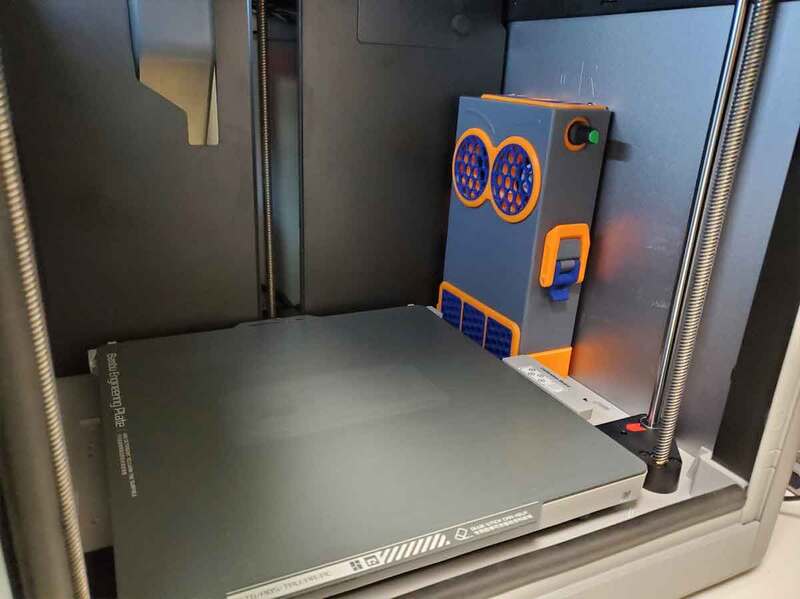

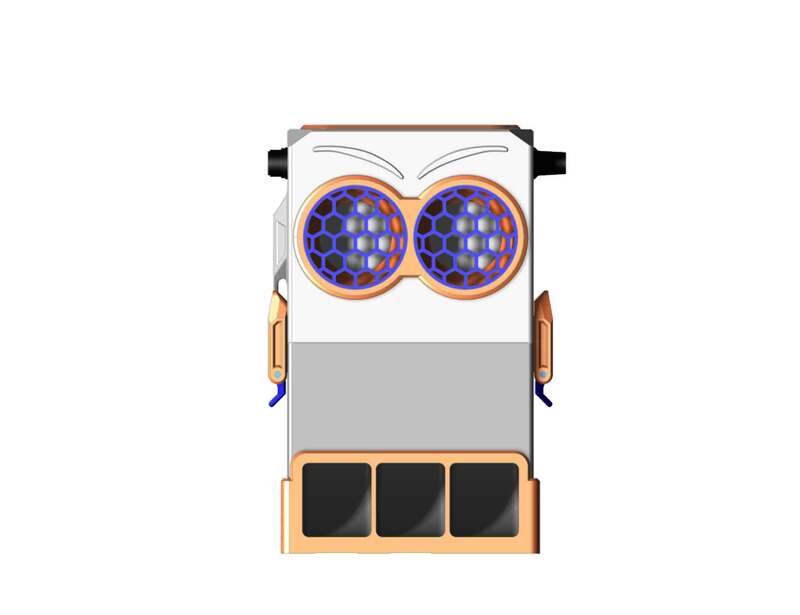

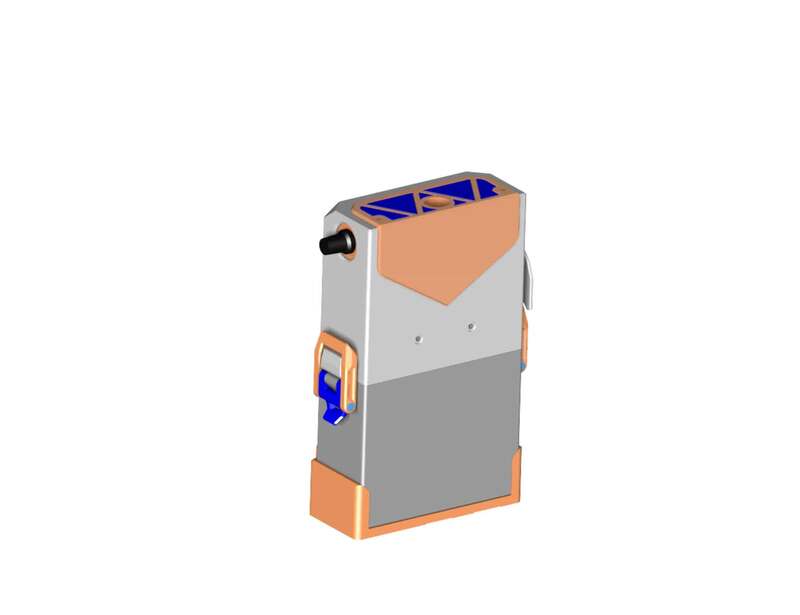

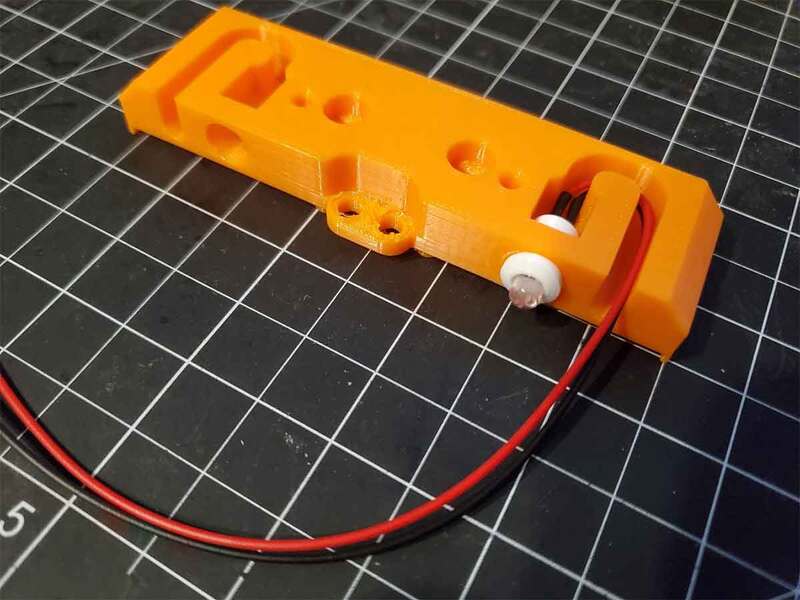

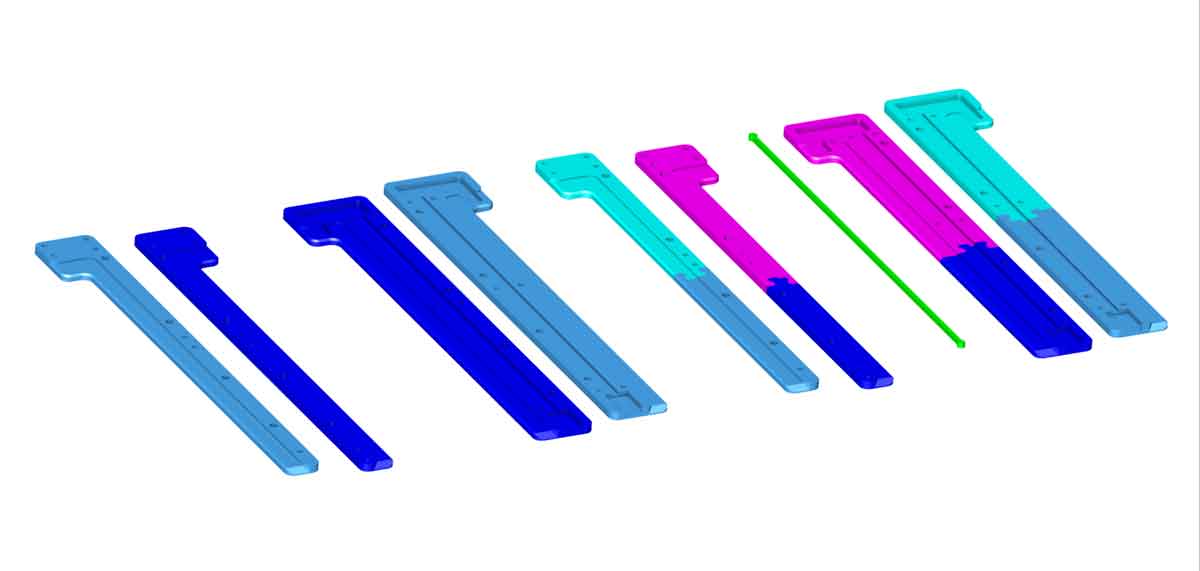

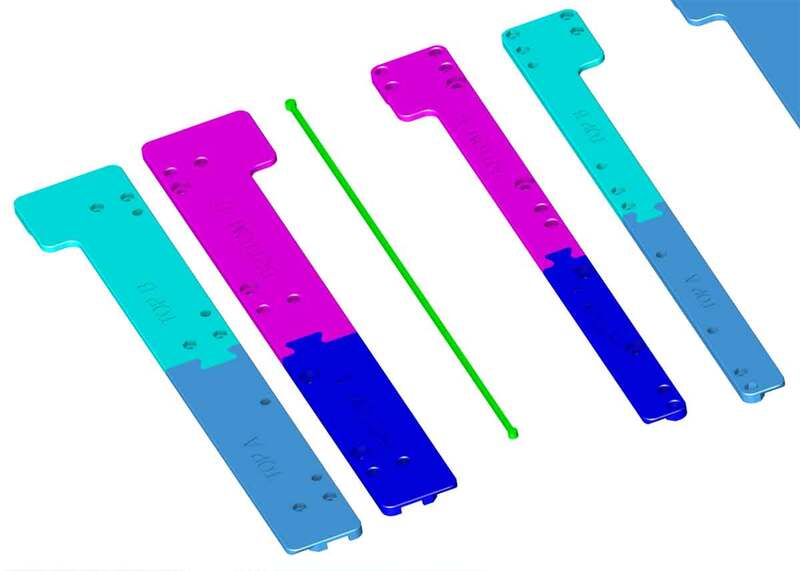

There are a number of optimizations which have touched on almost every part of the design, from the door springs to the wiper holders. It's a good thing I enjoy doing this as a hobby, or it would feel like work, lol. Below are some renders of the final design. My prototype tool box however will not look as good. It has many final parts, and some which I don't plan to reprint, since the changes are minor. I have very high confidence in the final design though, since I've previously tested the changes with smaller sections of the model (or the changes were just an adjustment of a dimension... or a hole). My prototype on the other hand, has holes drilled in it, and some other less than perfect aspects, but it's still functional and will be 95% as good as the final design. I'm just not gonna waste the filament to print the final design, and will live with the imperfections in my tool case. They will remind me of what a pain in the butt it was to make :D.

And don't worry glue stick lovers, two of the snack sized sticks will fit in one of the smaller compartments.

This will get posted soon, I just need to find the time to write up a BOM and assembly instructions.

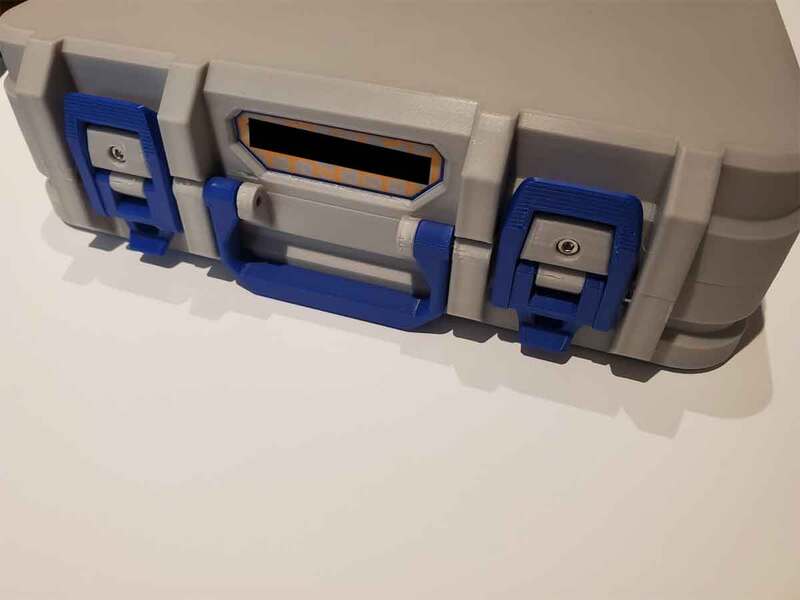

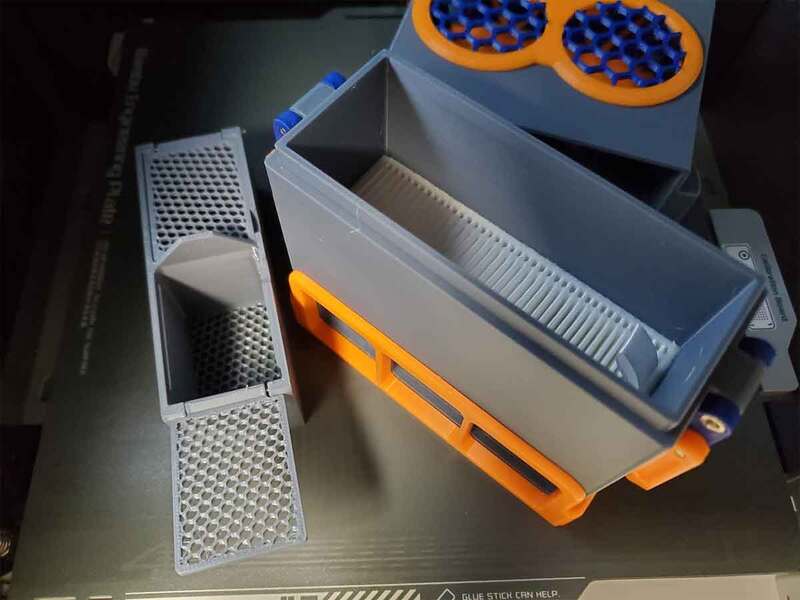

I took some pics of my (far less than perfect) prototype case, this is about as good as it can possibly look :D

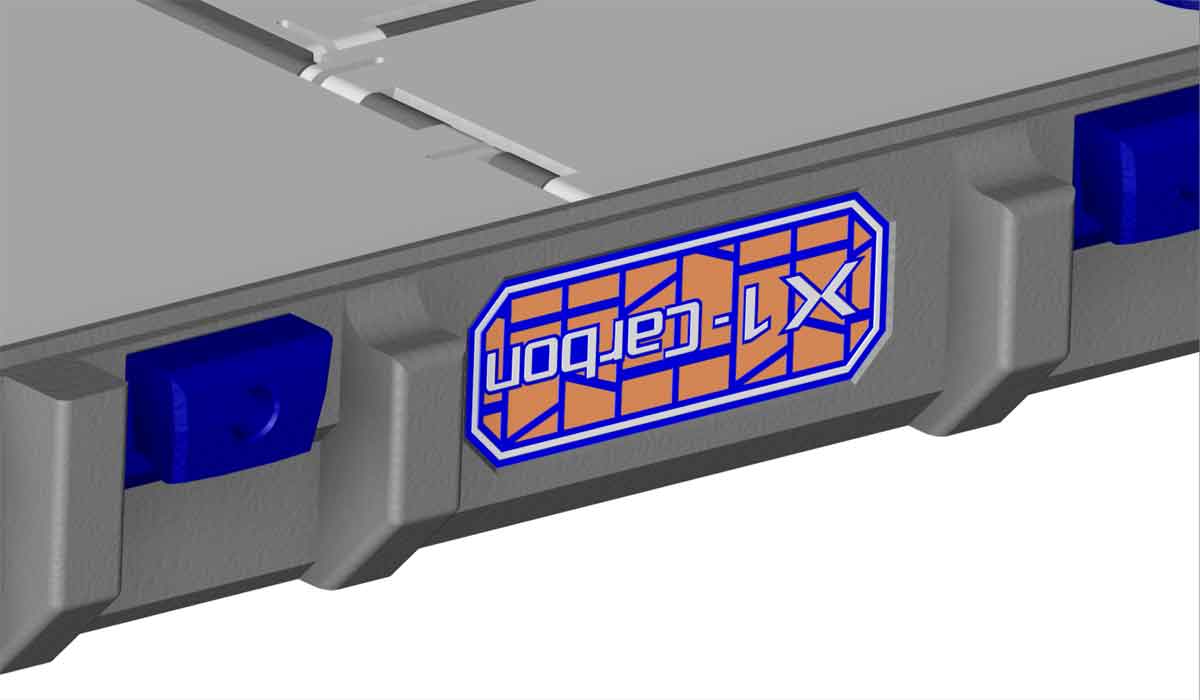

The case will be released without any "Bambu Labs" or "X1 Carbon" stuff on it, (edit) but I need to check if adding those logos to user created models is acceptable to Bambu or not (though I know there are tons of models that use it). In any case, it's gonna take some time to get it posted, as I need to export all the files and write it up.

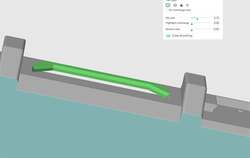

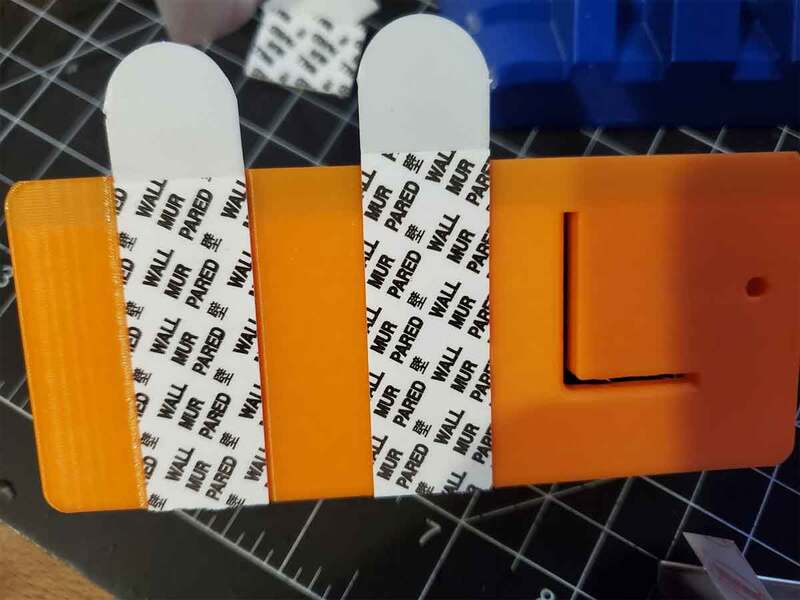

Update 10/9/2023: The design is as done as it ever will be, and the modification has been tested. The top will still need supports, but only in one very small area (see the first pic below). It will now require a couple additional M3x10 screws to mount the latch hangers, but the profile is much cleaner on those parts, since they can be printed in a proper orientation.

I emailed Bambu about their logo policy on the 7th, to ask if they are OK with putting the Bambu logo on this case, however I have not heard back yet (understandable since it's probably not a common question). I will give them a week, and if they don't reply, then I will just release it without the logos and markings. I will still keep an eye out for a response though, and will respectfully ask that folks don't remix the logo on this, since I have put a lot of work into this, and would like to do that if possible (only if it's OK with Bambu). I know that there are tons of designs out there with the Bambu logos, but I don't plan to add it to this without knowing they are OK with it. I recall seeing a very reasonable logo policy at some point (possibly during the kickstarter), that (as I vaguely recall) probably would have allowed adding the logo to this, but I can no longer find the policy on their website (so don't quote me on that :D). I'd rather not run afoul of Bambu, or give them a reason to take down the design (as unlikely as that would be), and clarity on their policy would be generally a good thing.

Update 10/22/2023: Bambu support got back and gave me the green light to use the logo on this design, so I will be uploading it later this week in all it's logo adorned glory!

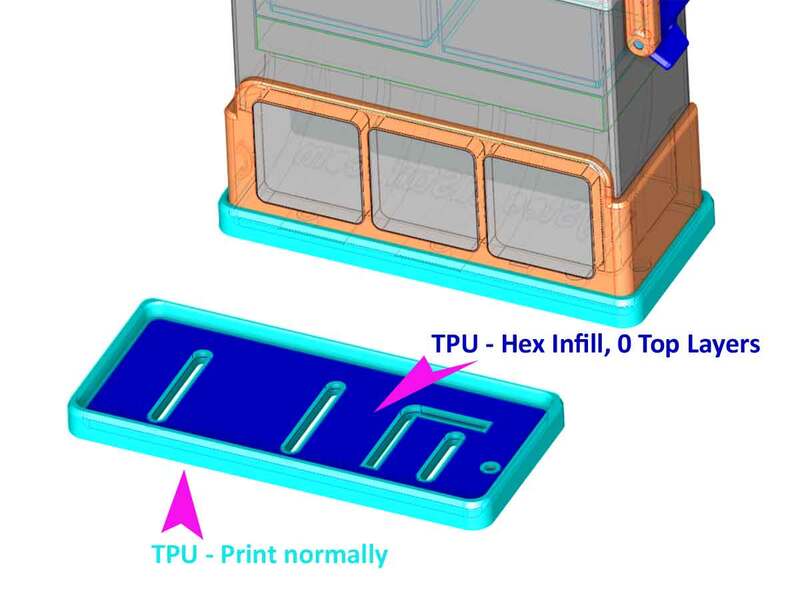

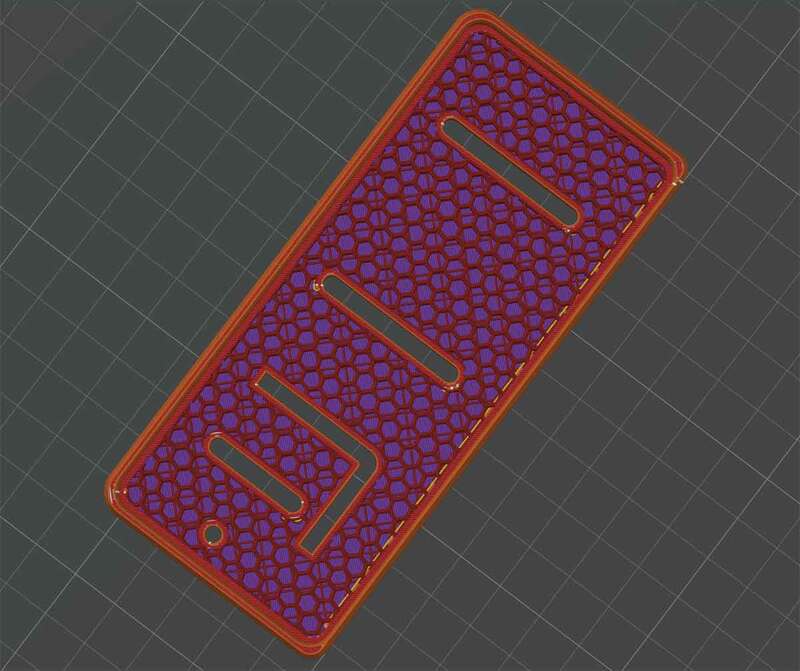

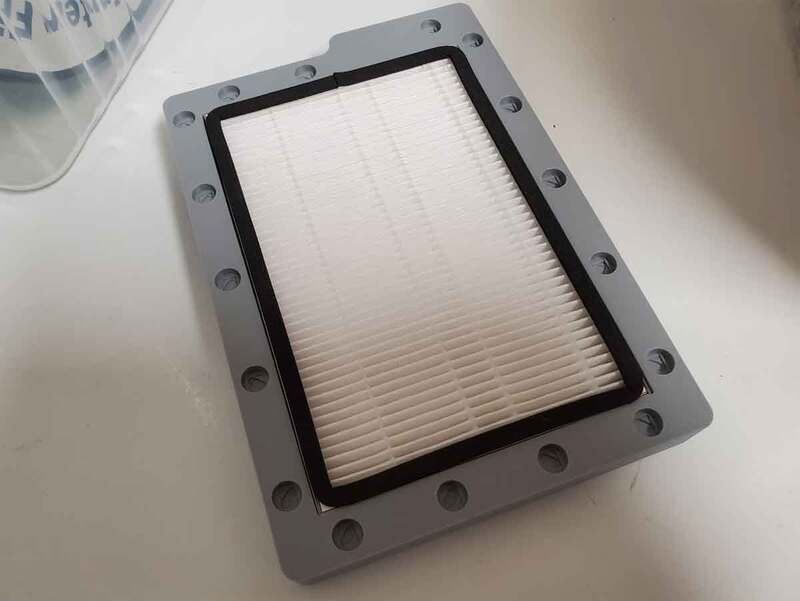

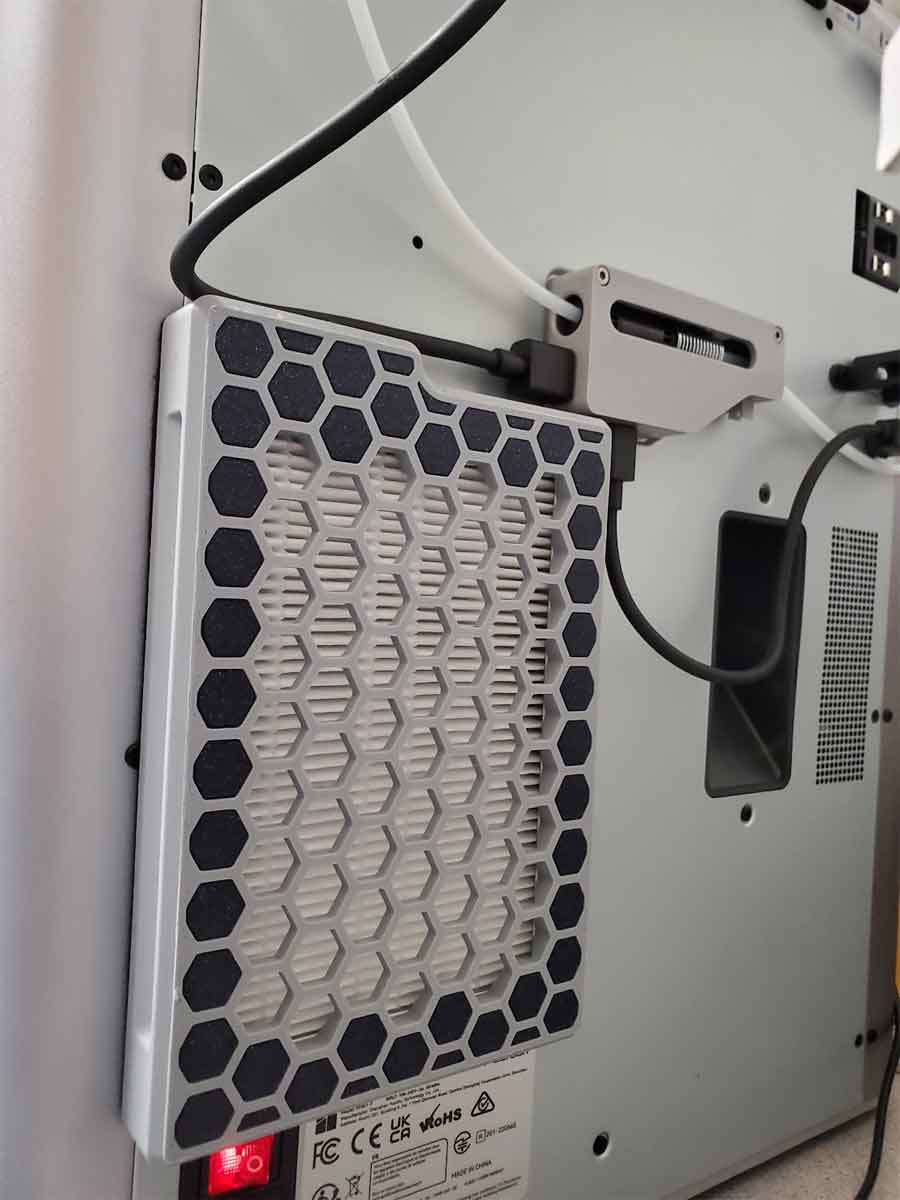

Update 11/11/2023: Well I guess I lied, it hasn't been posted yet because I've been working on some improvements. The first is a gasket option, and the second will allow printing the whole model without supports. Part of the second improvement is a new label design, which I'm just waiting for my printed to get freed up to test. The gasket design is already tested and will be optional, since it requires being able to print TPU. Once the new label design is tested and I'm happy with it, I'm gonna just say "no more changes", and work to get it read to post.

https://makerworld.com/en/models/62636

https://www.printables.com/model/626897-bambu-labs-x1c-spare-parts-case-box-for-stuff

The build guide is also updated.

RSS Feed

RSS Feed