|

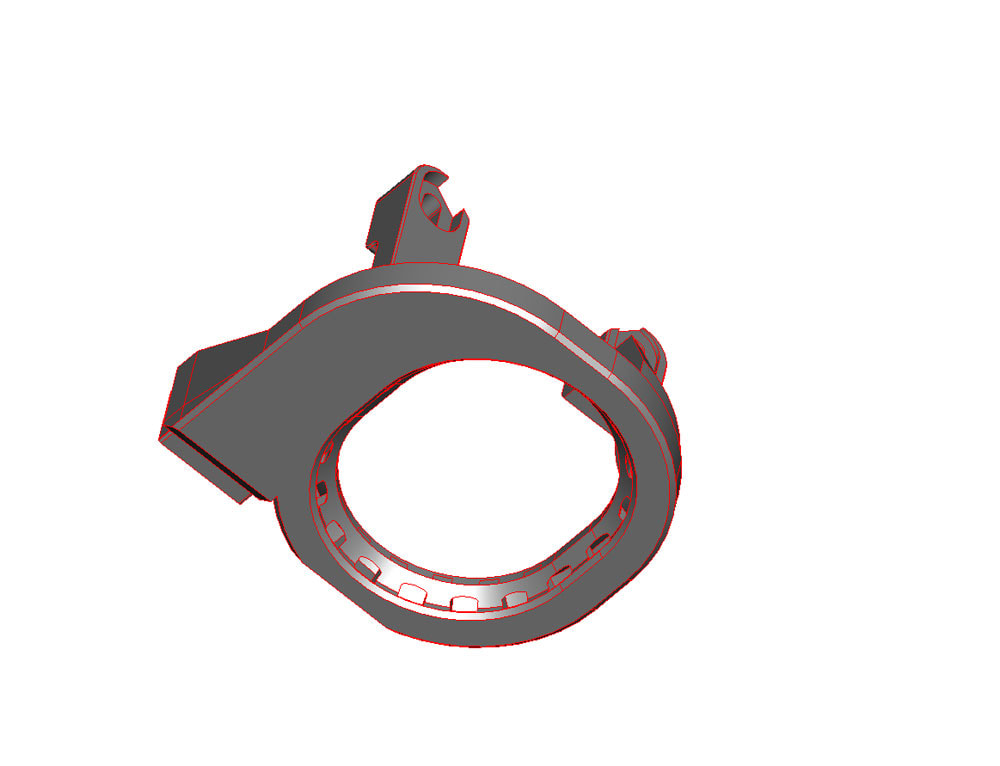

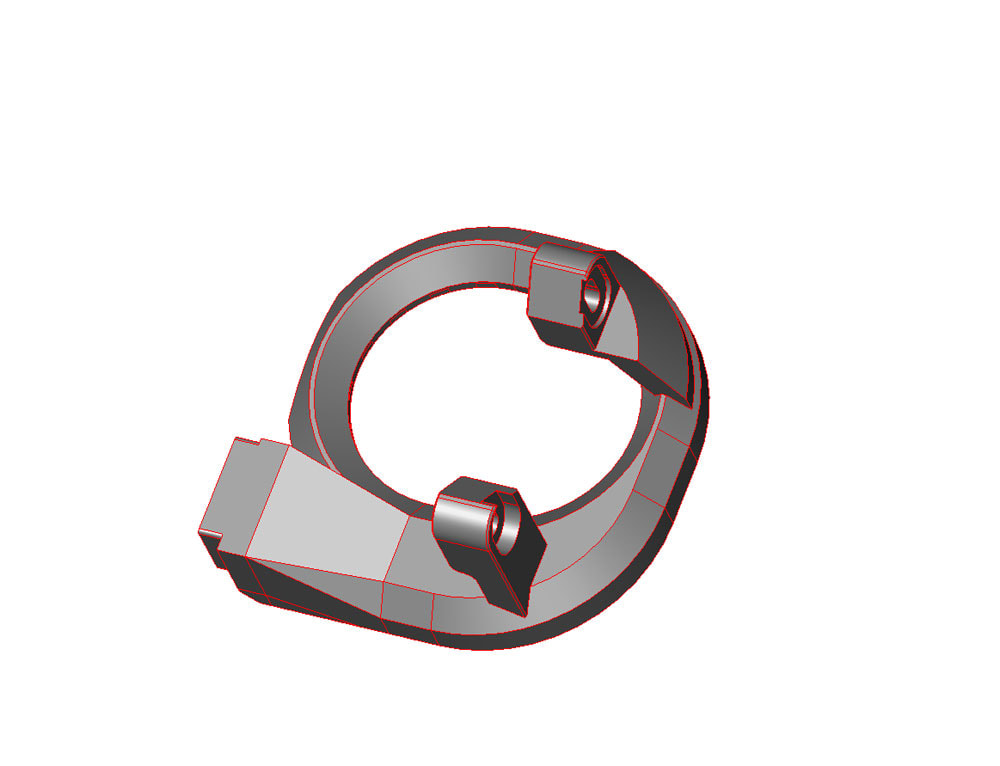

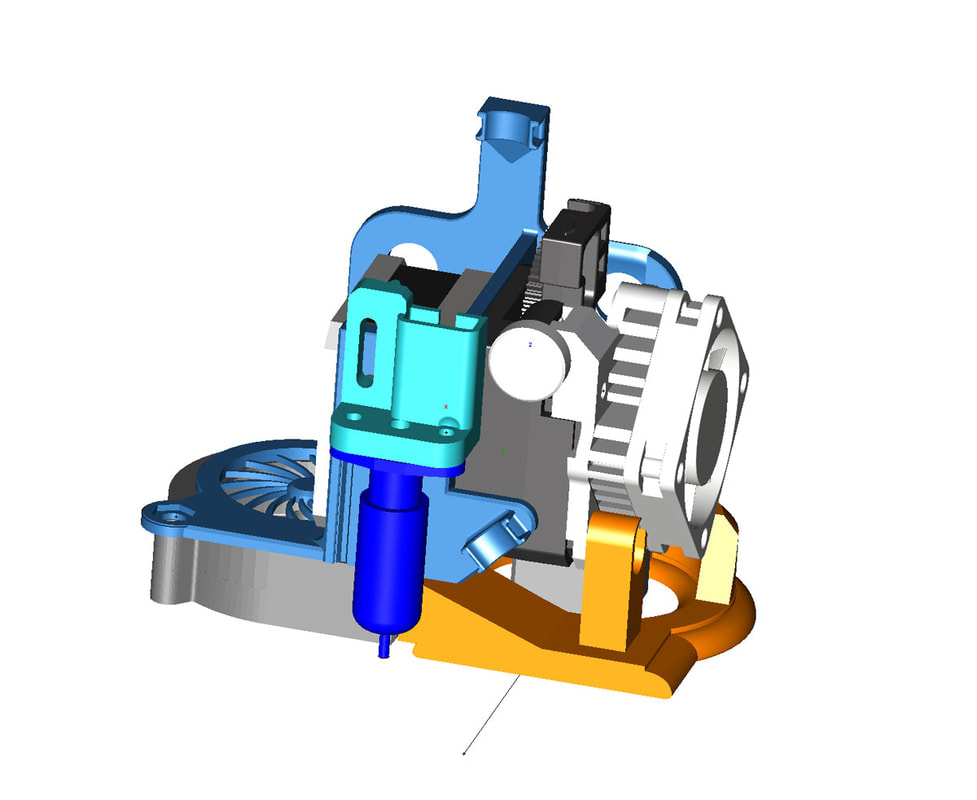

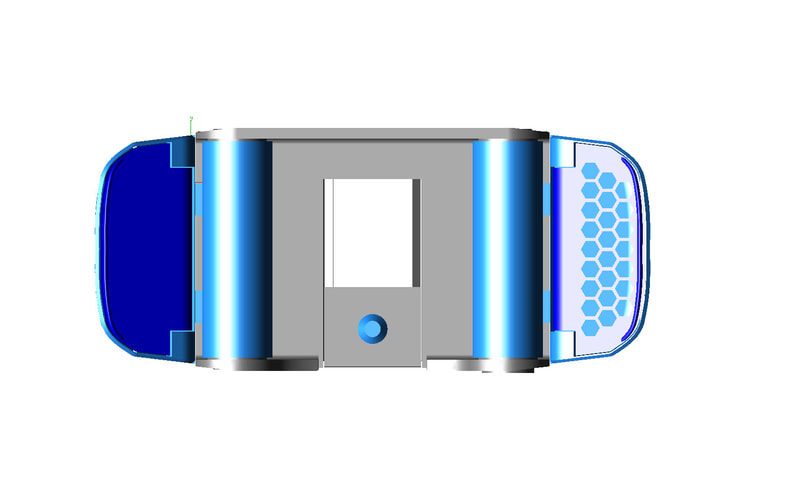

This has not been posted and may not be since there are a ton of better Titan Aero mounts for the CR10 / Ender3. My mount however has had one major issue which was the fan duct. The original duct was too close to the hot end, and over time the airflow became disturbed as the duct warped a bit. Also it was not low enough. I redesigned it to hopefully fix both issues and feel that this new duct should be pretty robust and offer a much less restricted airflow than the old one. The old version of the duct is below, and regardless of how well the new one works, I won't be going back to the old design.

3 Comments

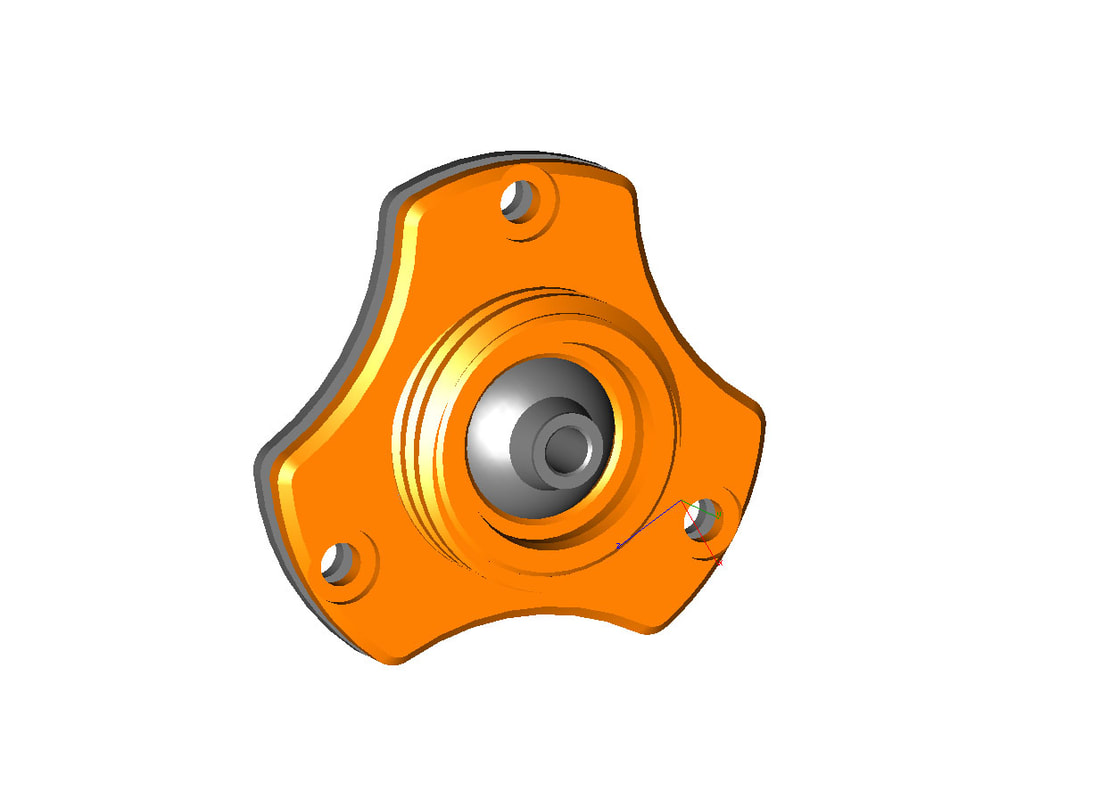

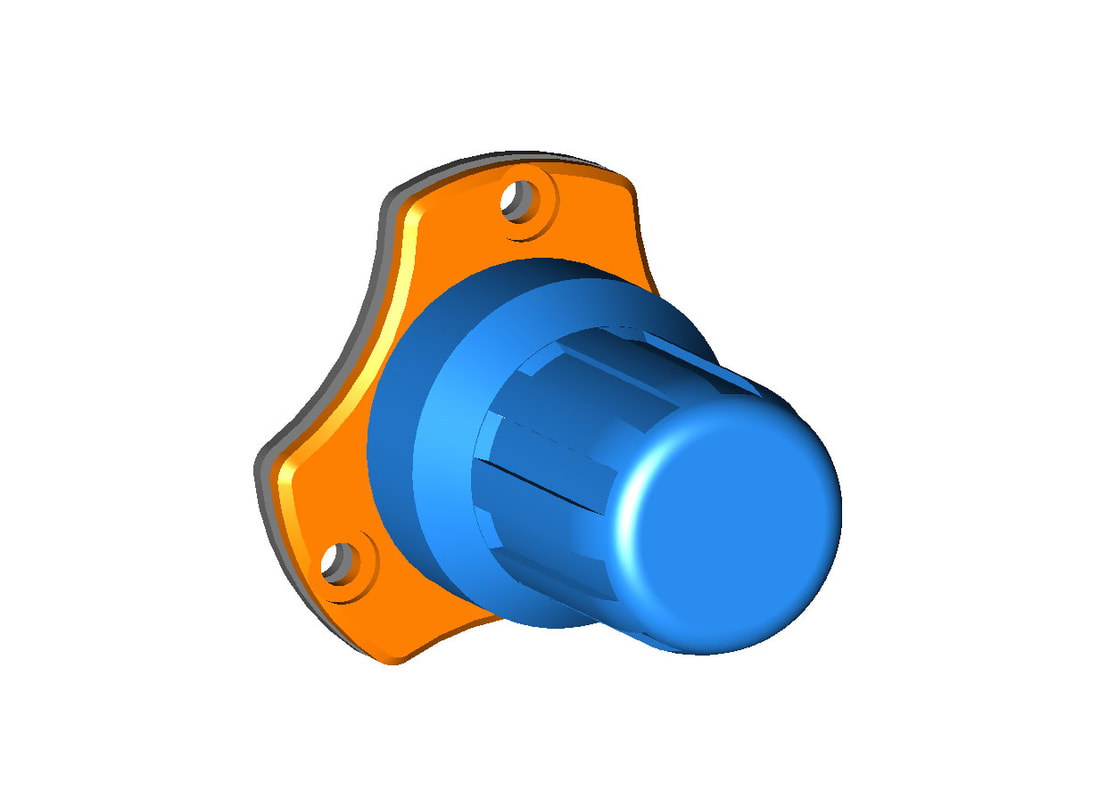

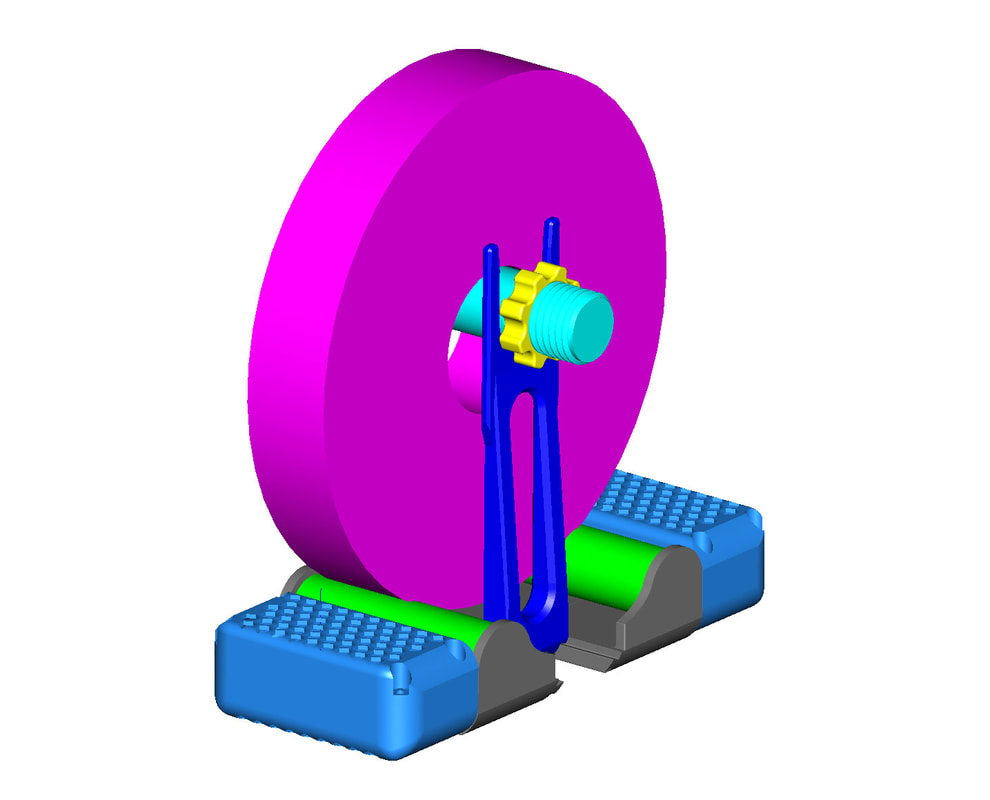

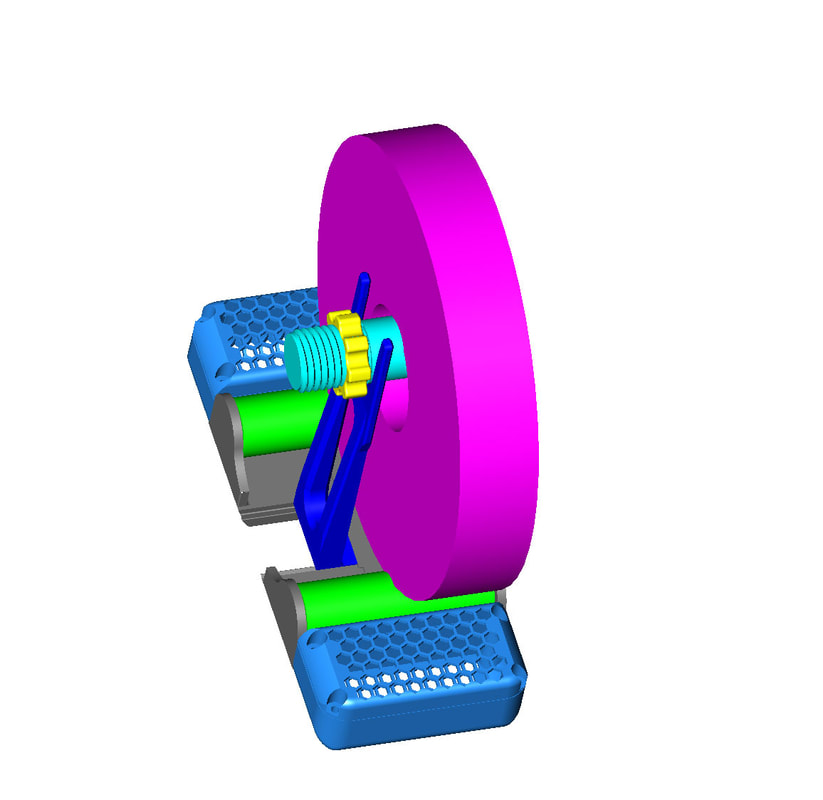

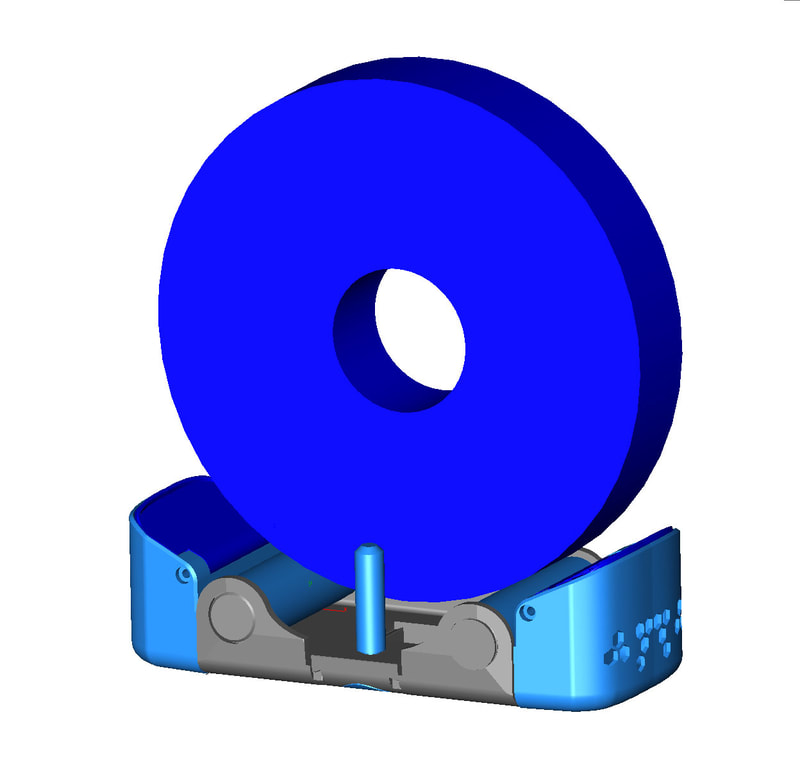

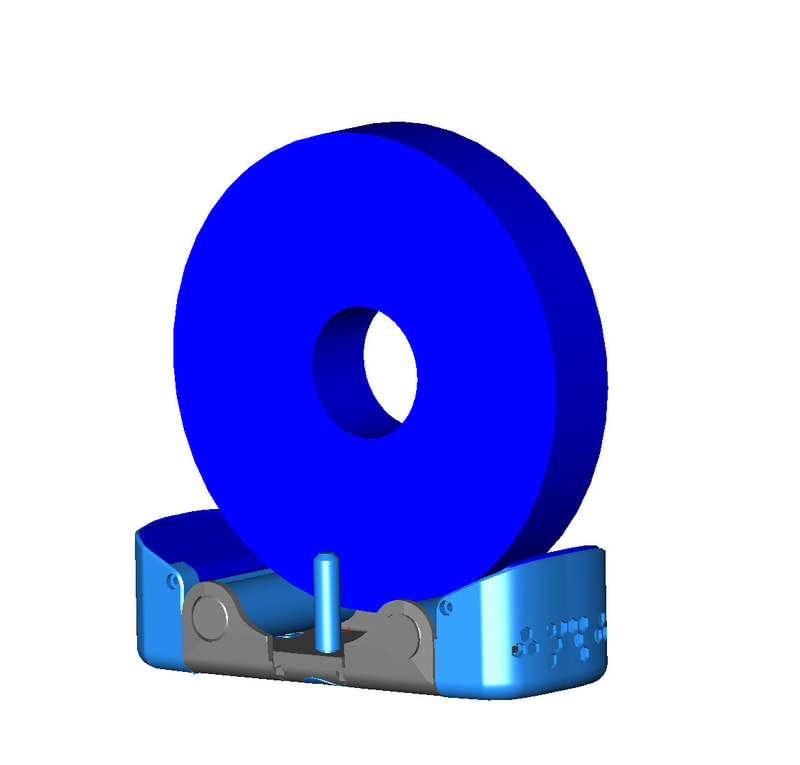

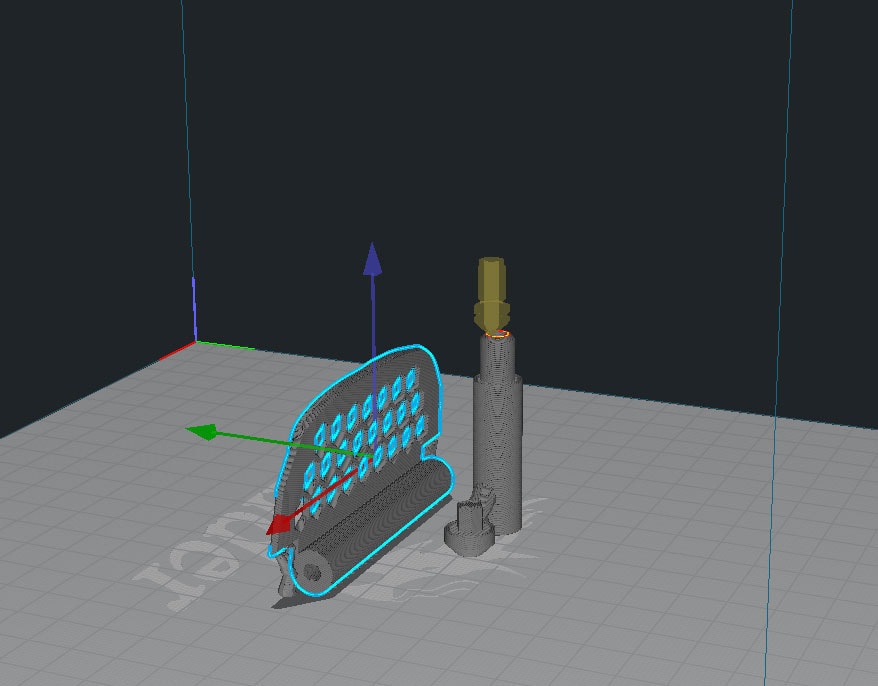

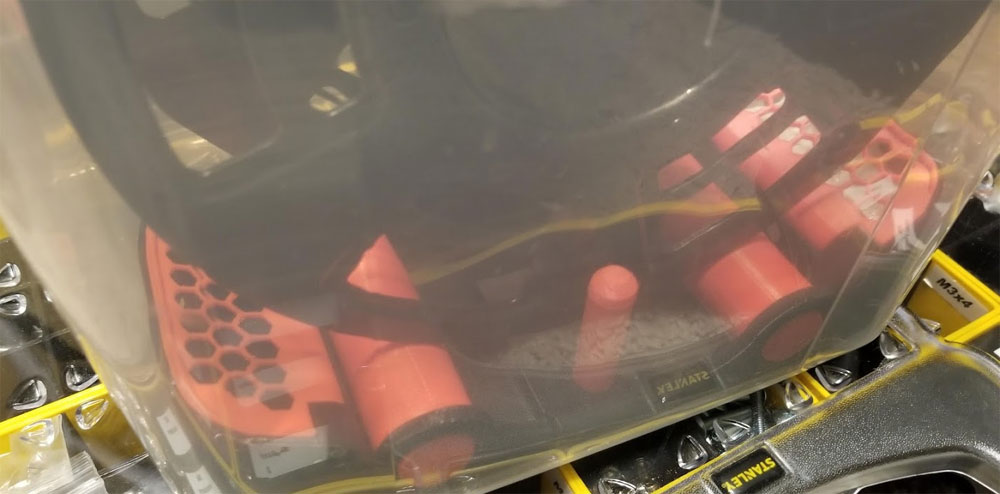

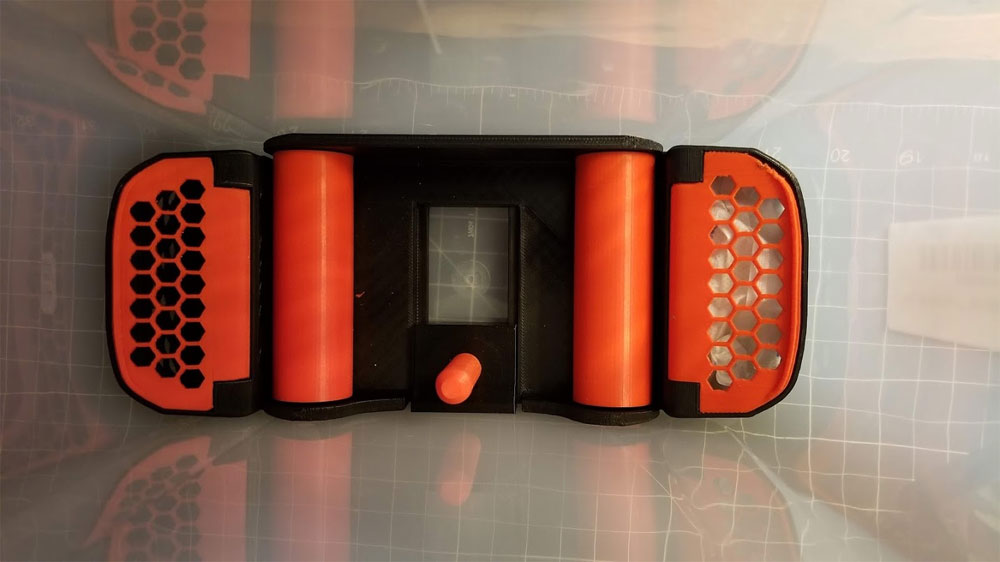

I bought some TPU to try out, but I read that the stuff needs to be kept dry, more so than PLA. I just keep PLA in bags and am not really good about monitoring humidity (but I have found that it seems to recover pretty well in a dehydrator). I checked around for filament boxes, and it looks like people use the rubbermaid cereal storage containers for single rolls, which should be air tight. One of those, and some silica gel beads should work out OK, but I want to keep the filament in the box while it is being used. That means I need to have a way to get the filament out of the box. I saw something like the design above on thingiverse, but I could not find it when I went back to locate it. Once I find it, I will add the link (UPDATE - here it is) , but for now, this is what my version of a filament pass through is looking like. It will have a screw on cap for storing the filament, and there will be an o-ring inside the cap, along with a place for another one on the back plate. I expect that I will need to use silicone around the screw holes and on the front plate, but the combination of o-rings and sealer will hopefully keep the box air tight when stored with the cap. Update 7/21/2019: The filament pass through is posted here. Update 6/20/2020: Updated and improved version posted here. Update 7/20/2019 - The design for the filament box is almost completed and I am pretty sure that the remaining changes will not affect the way it fits or works much. The major changes from the initial design was to drop the part that that goes through the center of a spool and just have it roll. To help wrangle the smaller spools, there is now a small vertical roller which slides in a dovetail track. The final design adds a rubber band to keep some tension on the vertical roller. You can find the final design (not fully tested yet) here.

|

Stoopid MeWelcome to my Stoopid corner of teh Internet. It's mostly gonna be 3D printing stuff, but I also post some recipes, projects, and the occasional rant here as well. More Stoopid stuff is updated regularly. Archives

July 2024

Categories |

RSS Feed

RSS Feed