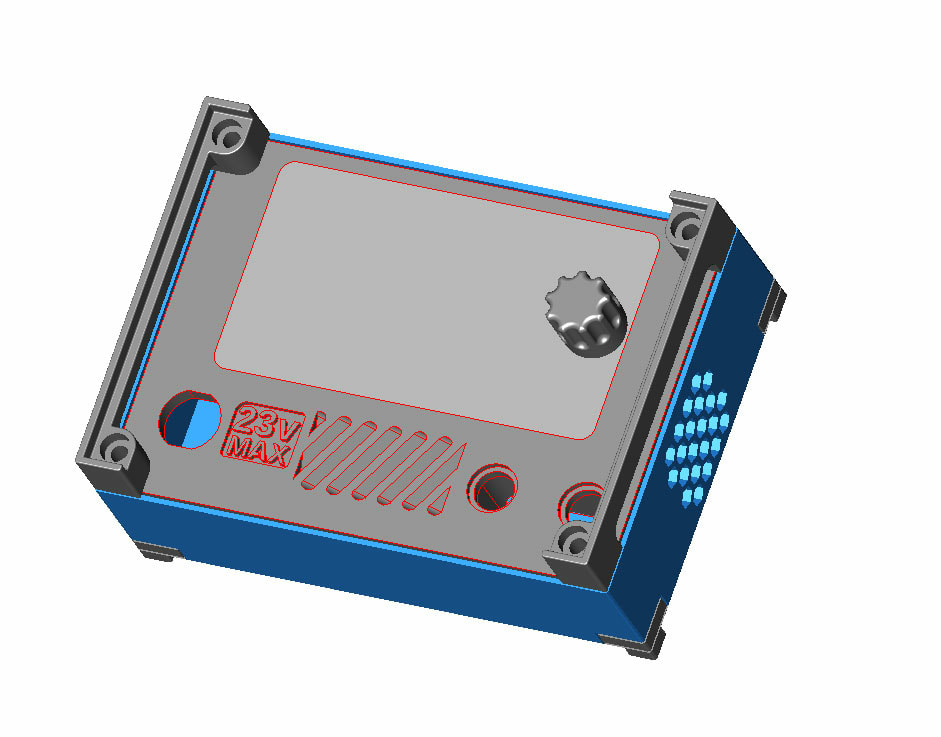

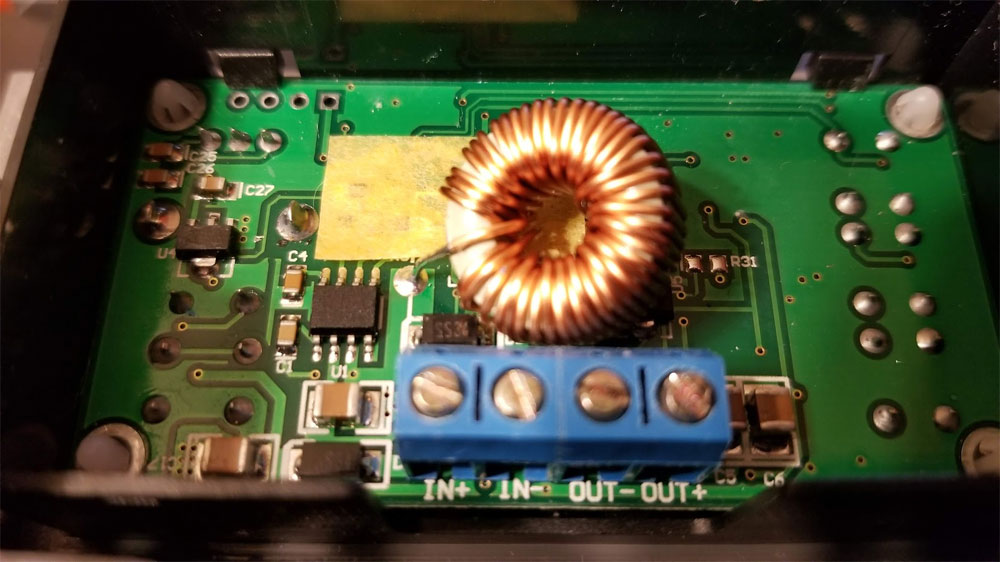

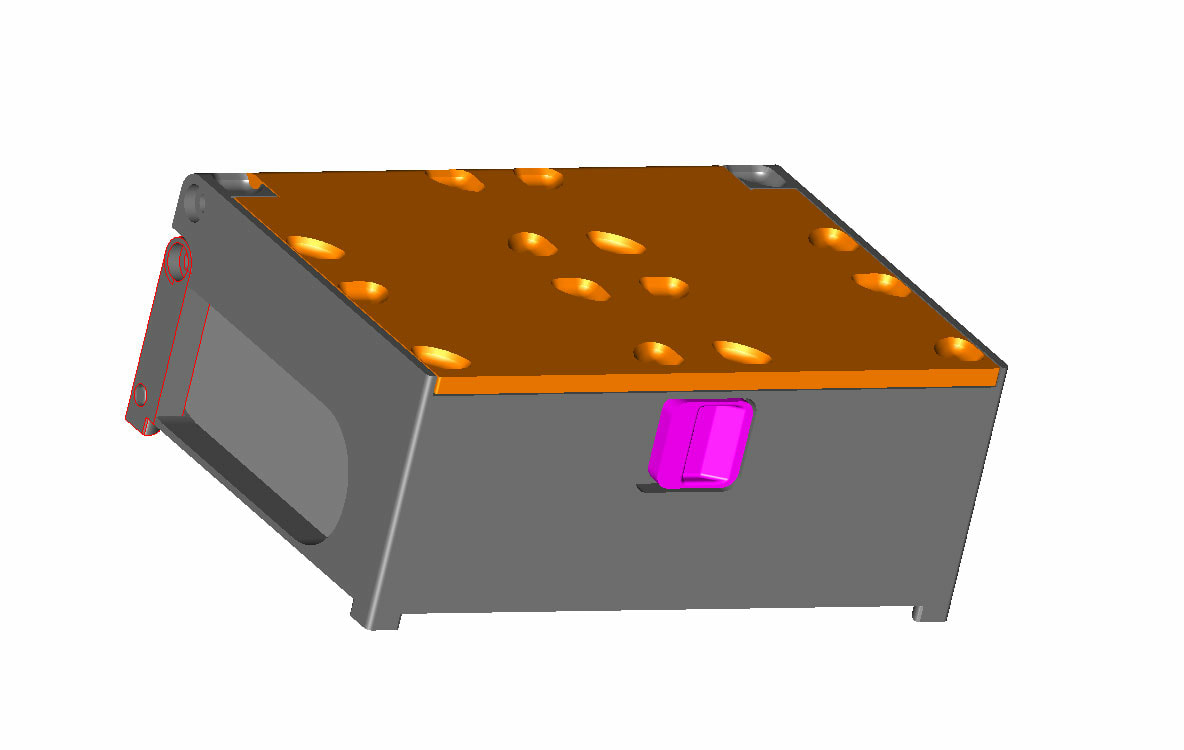

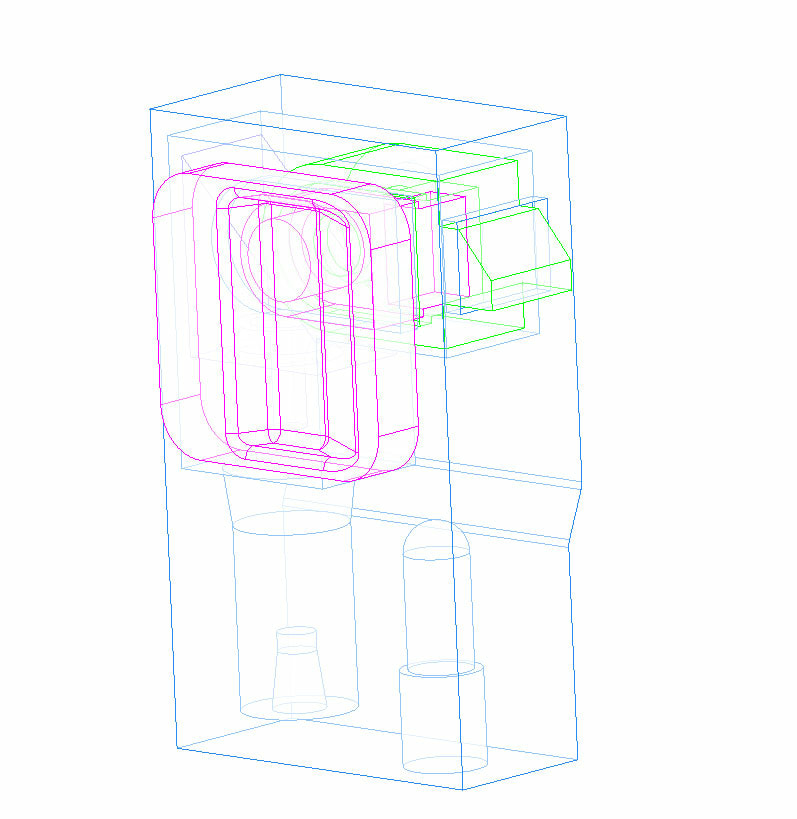

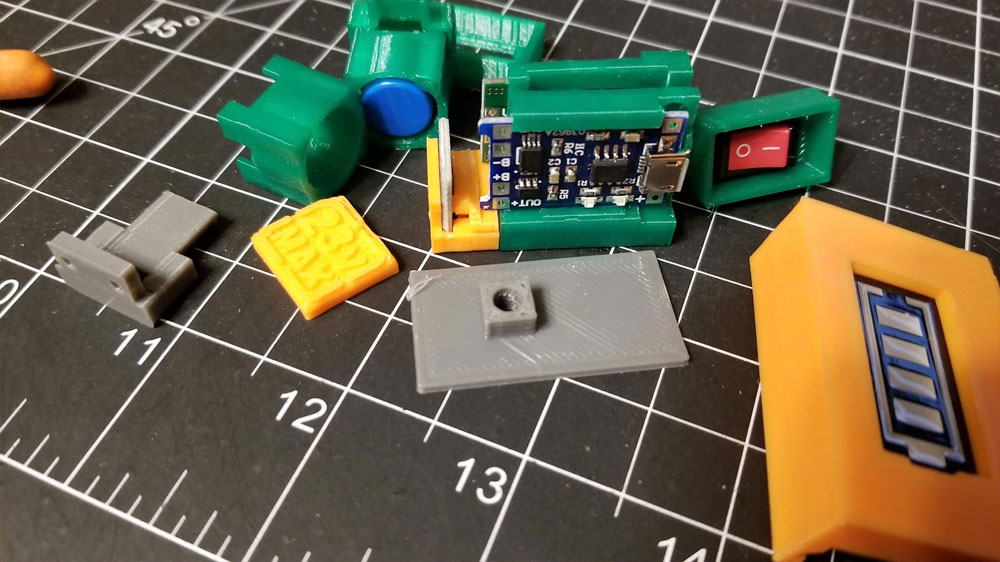

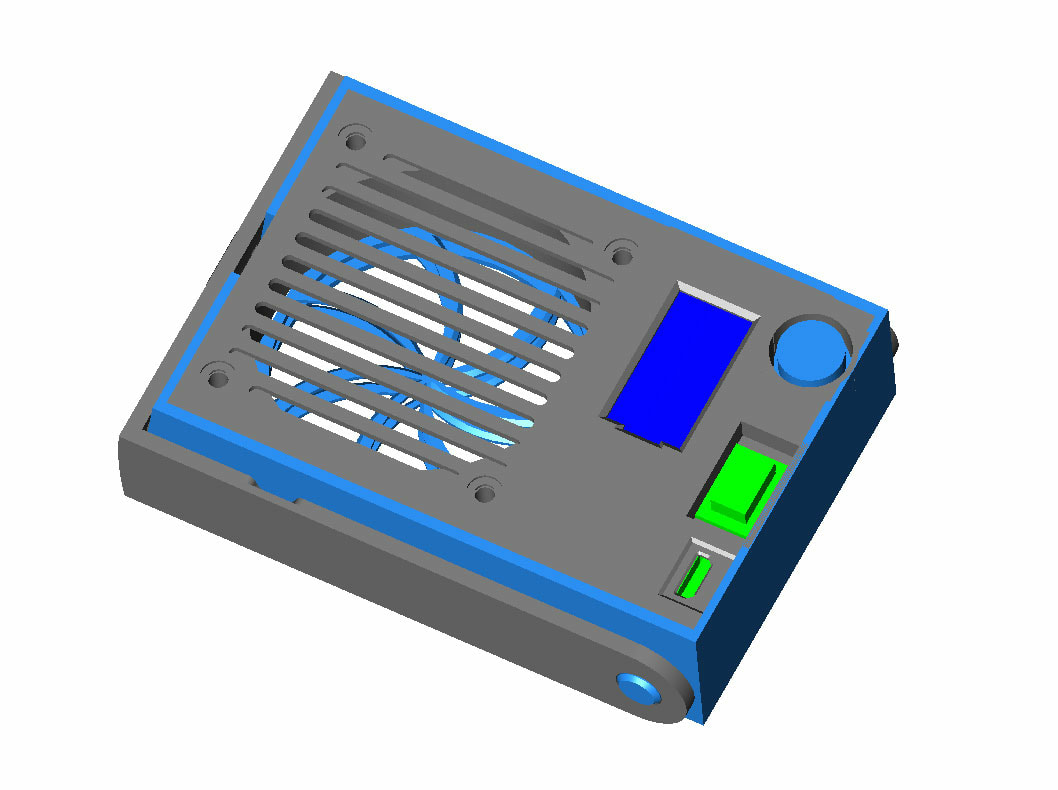

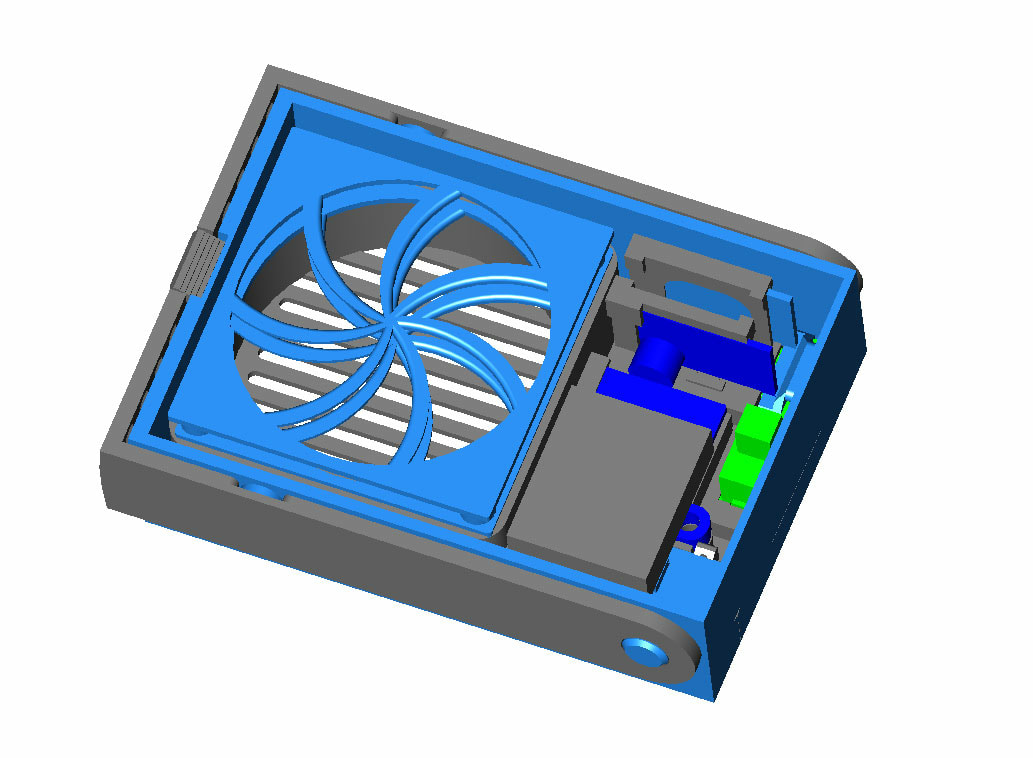

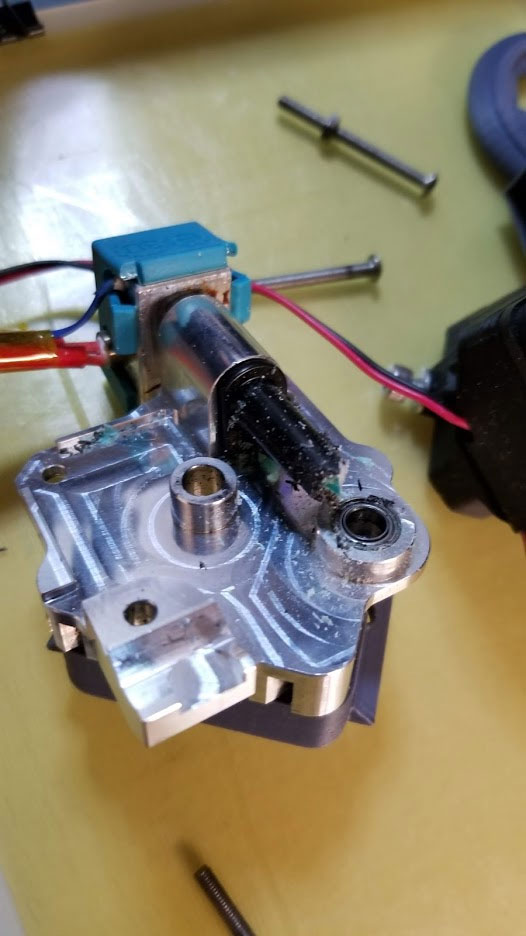

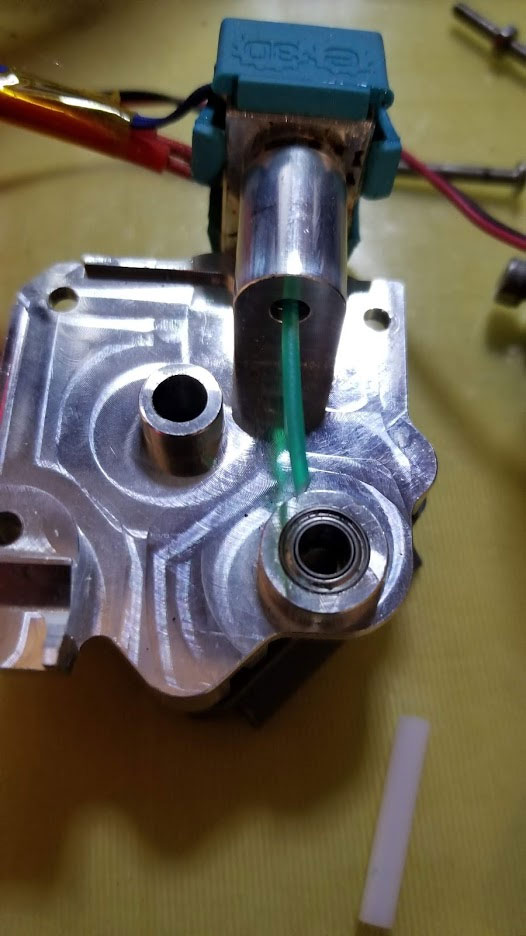

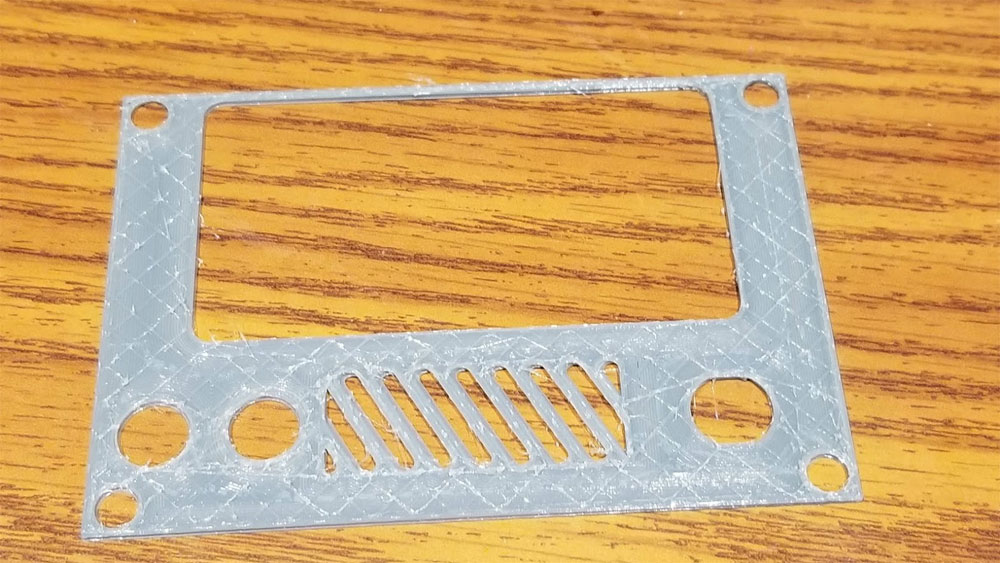

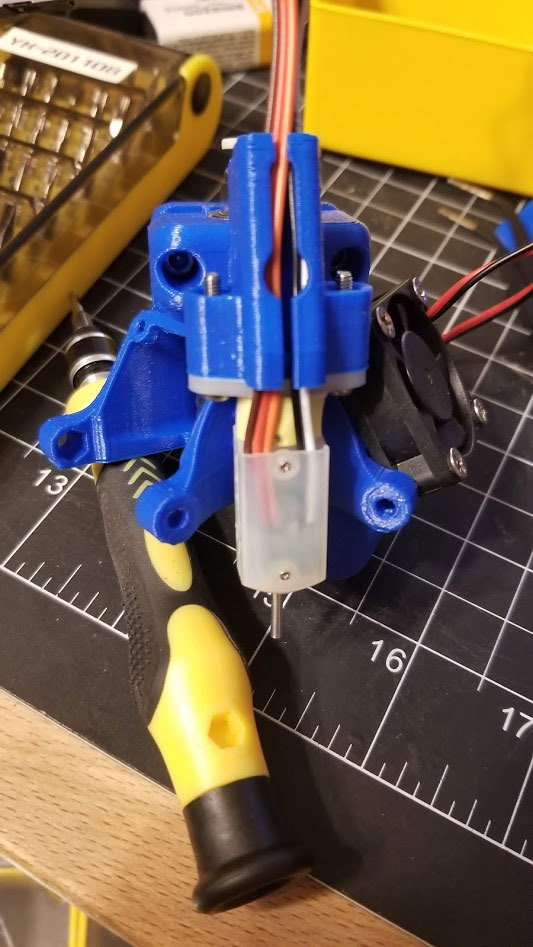

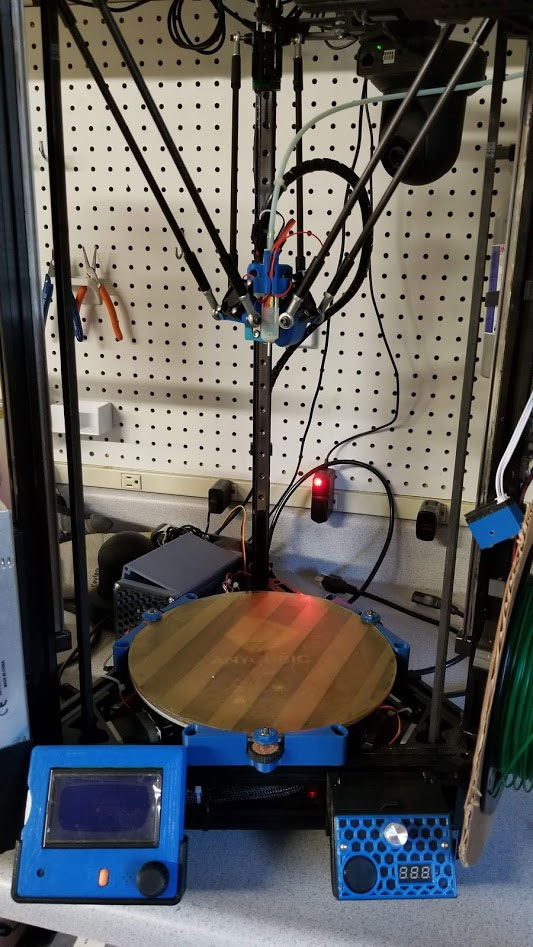

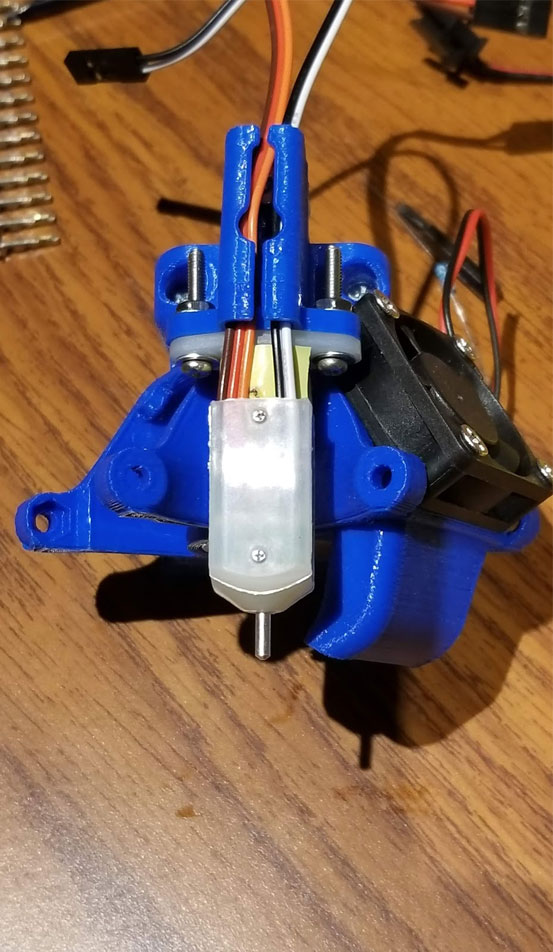

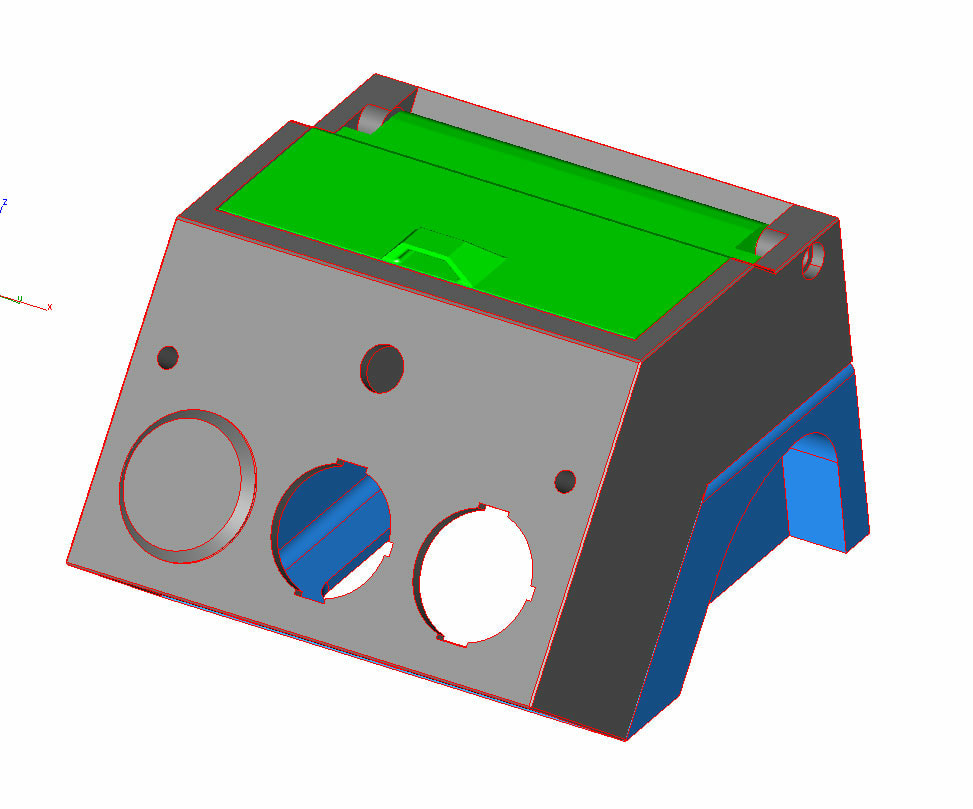

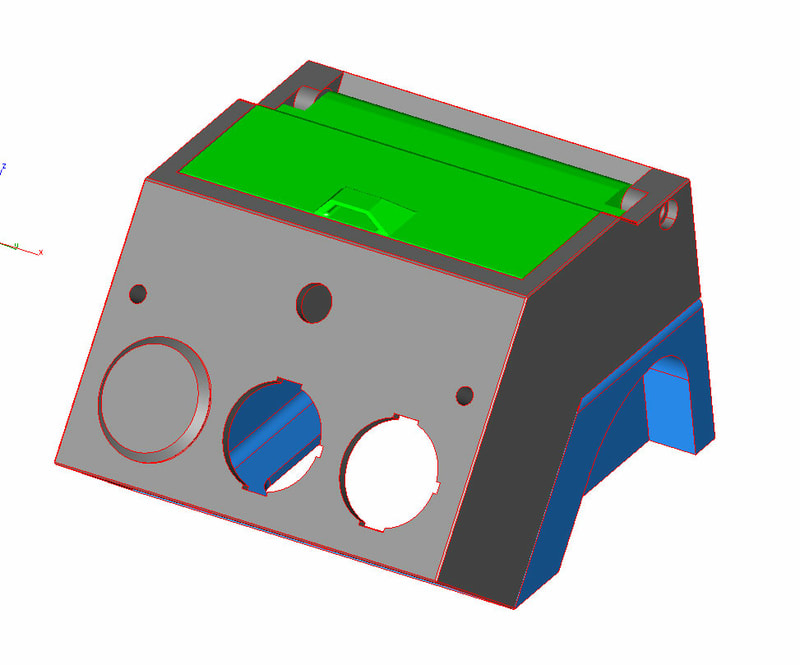

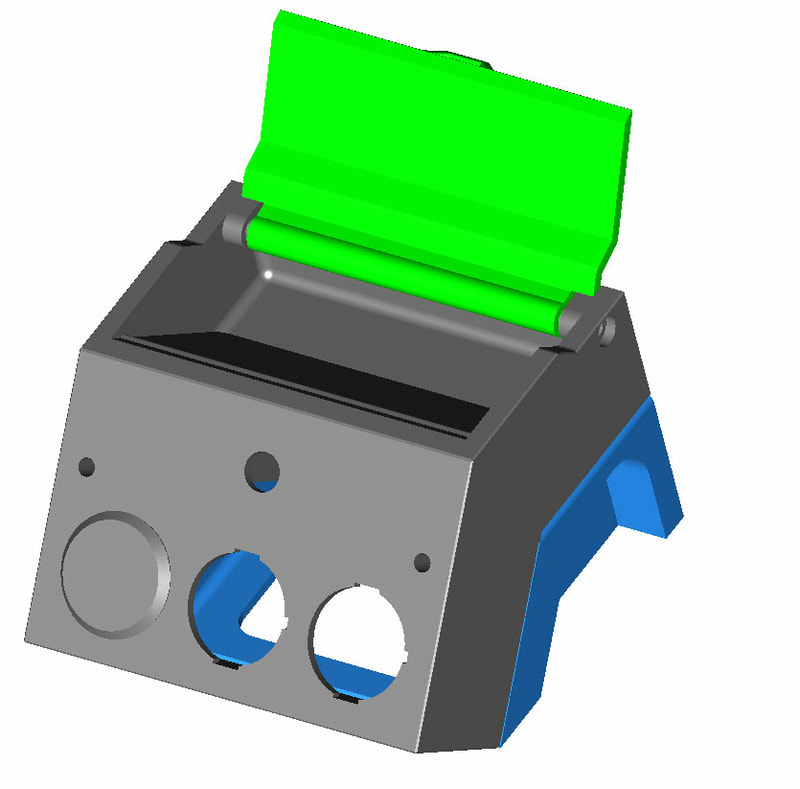

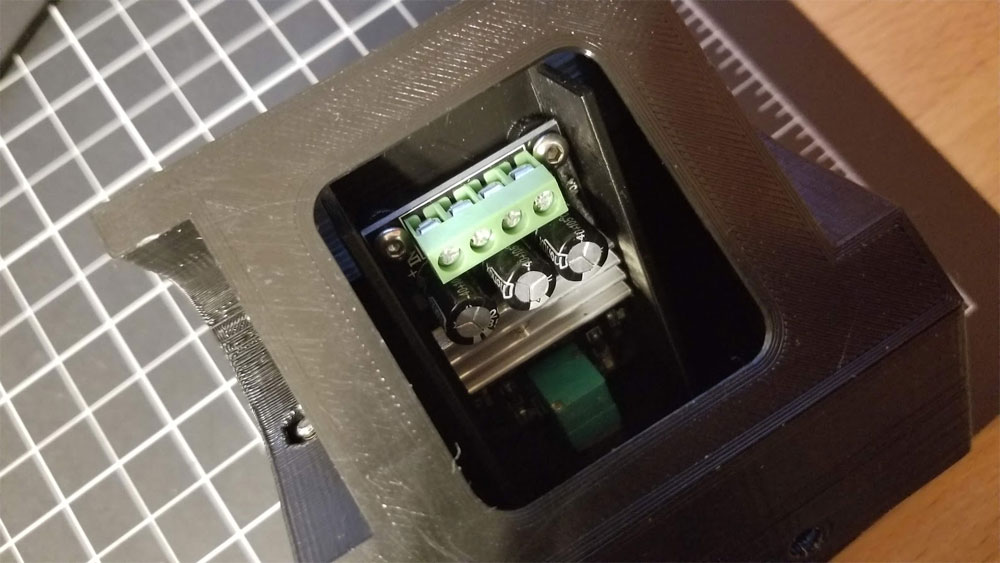

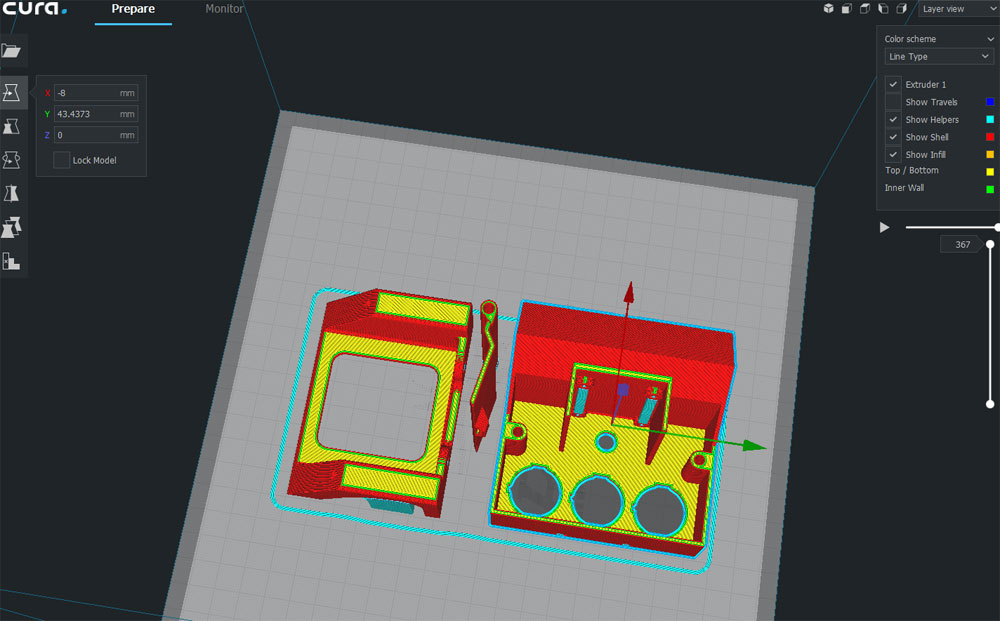

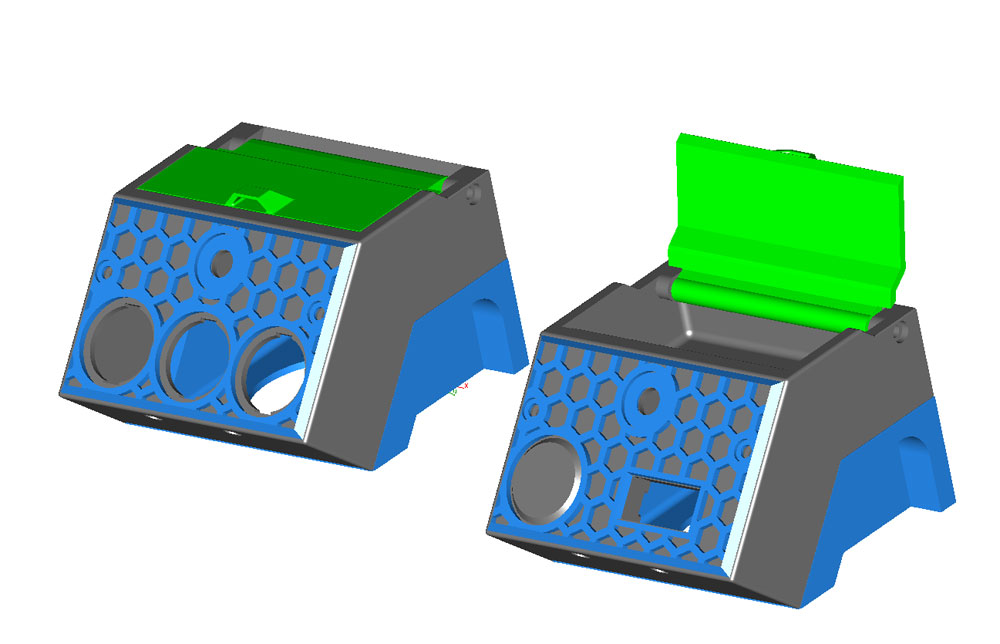

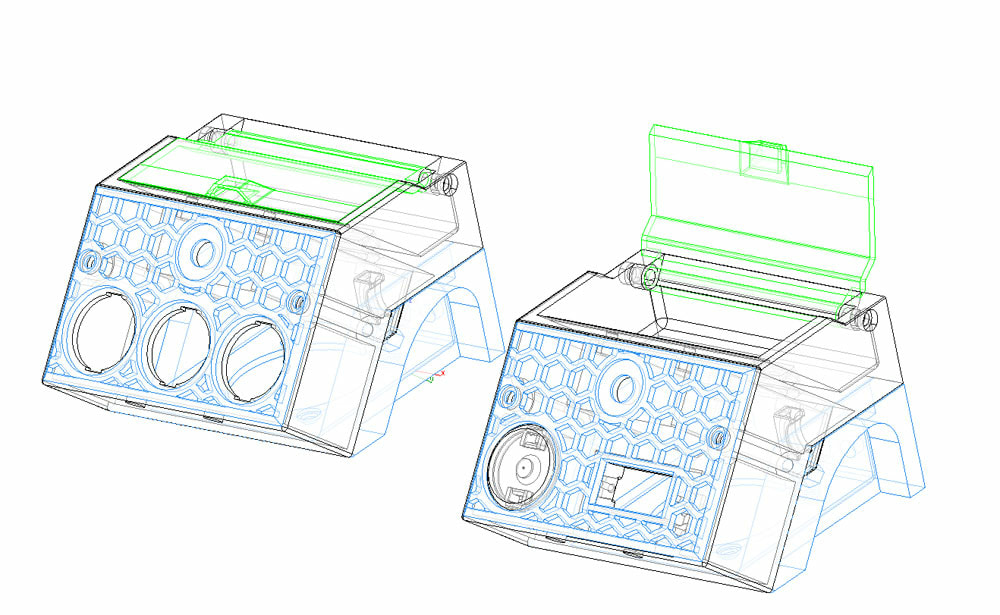

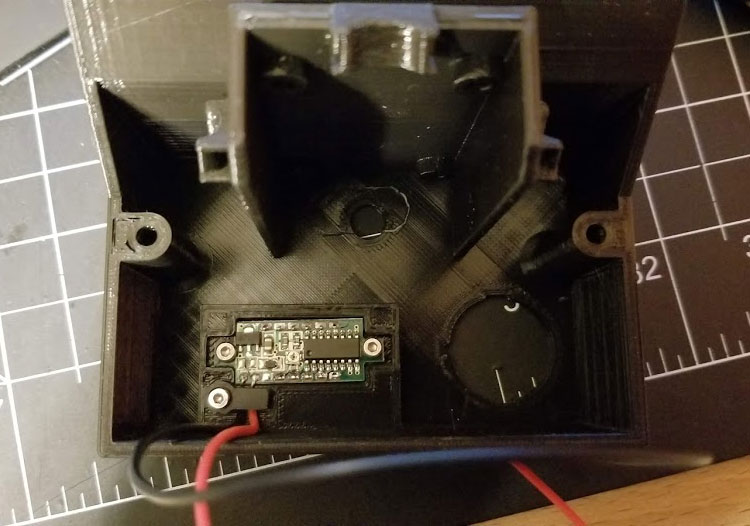

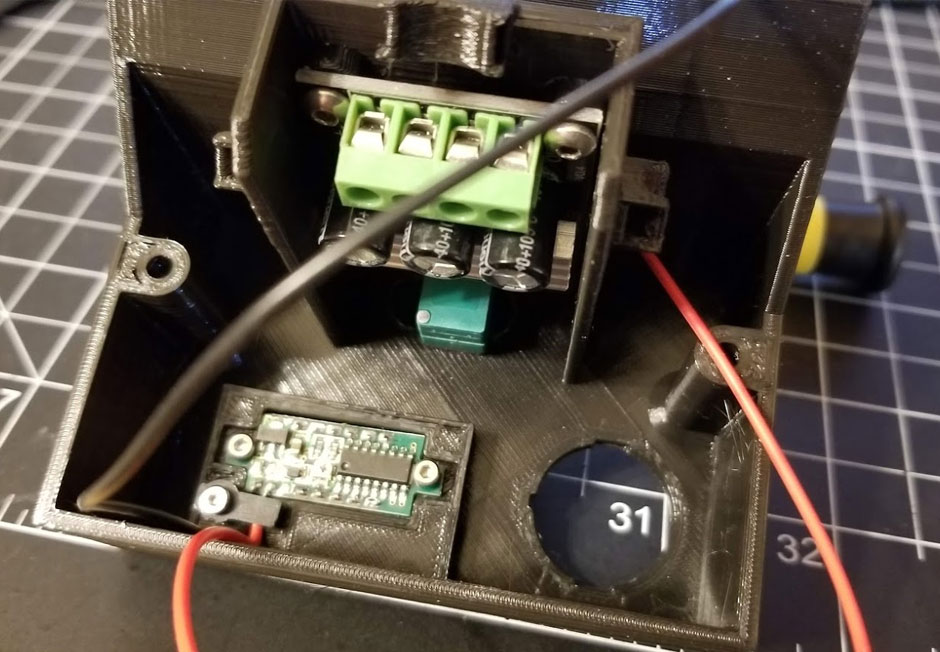

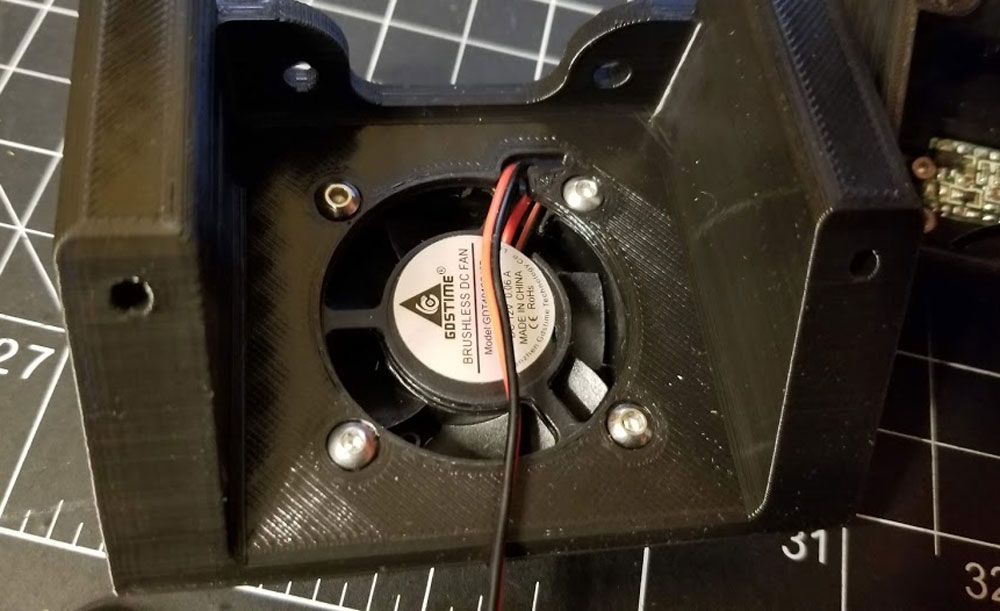

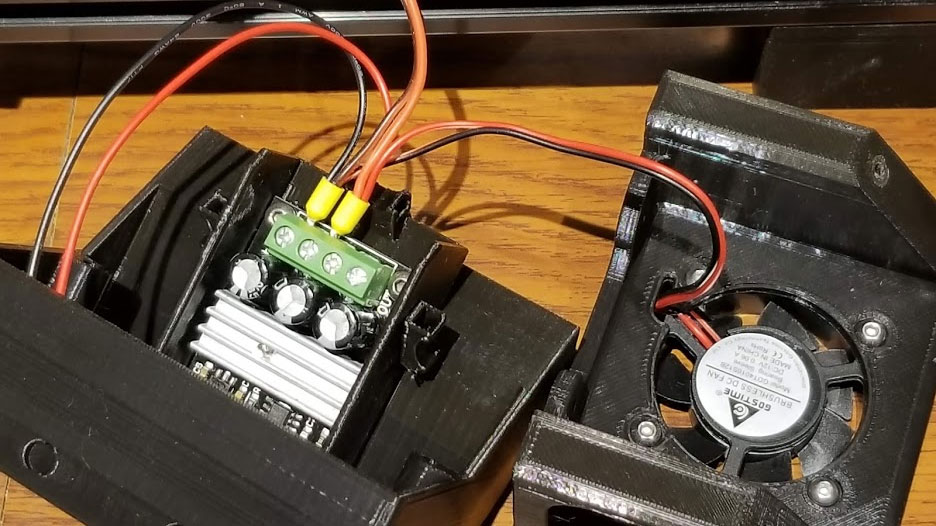

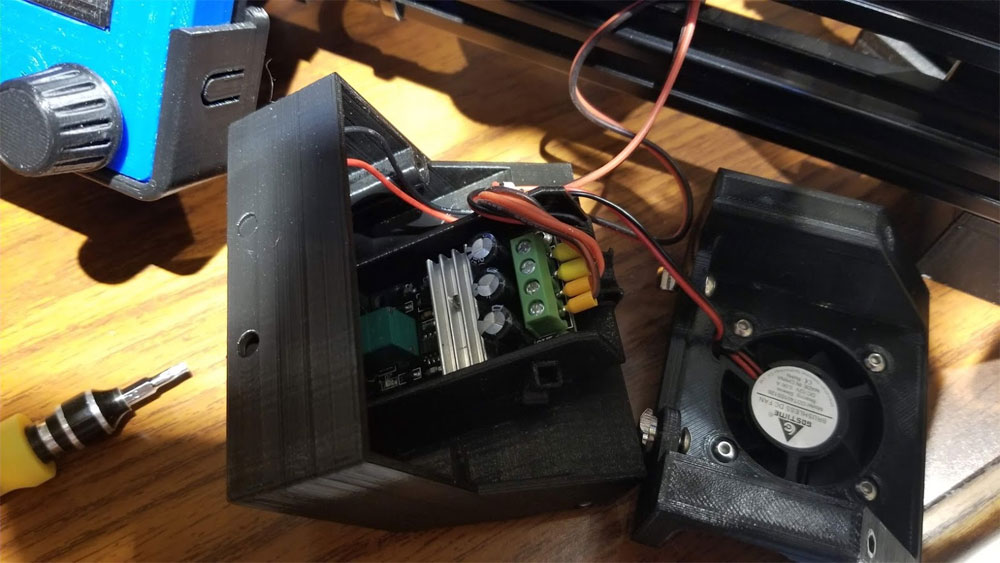

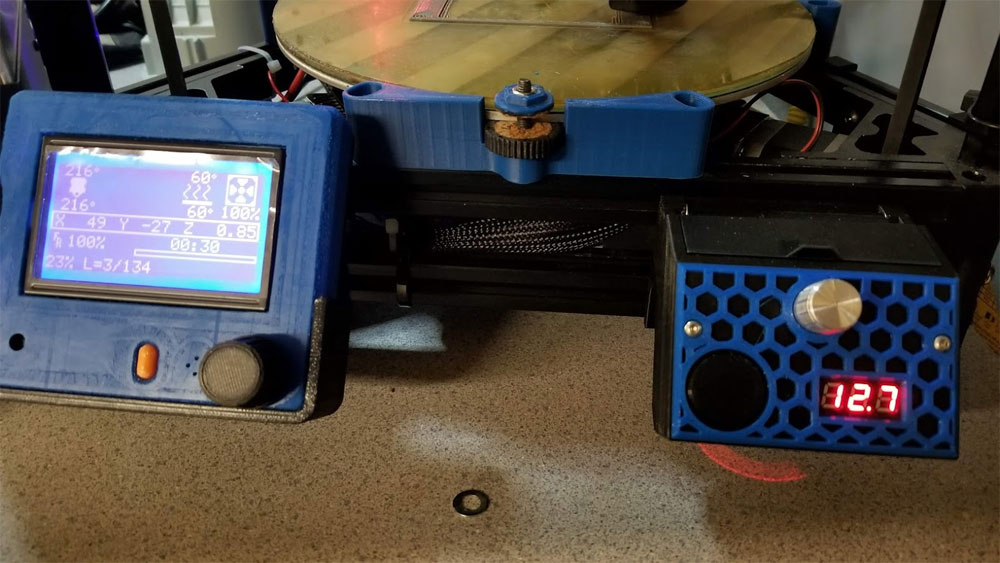

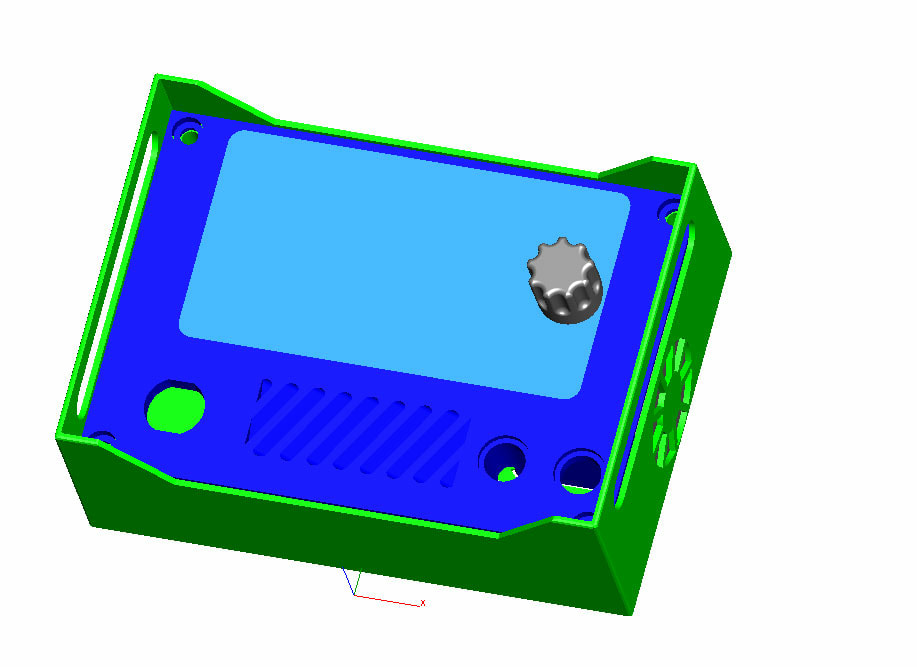

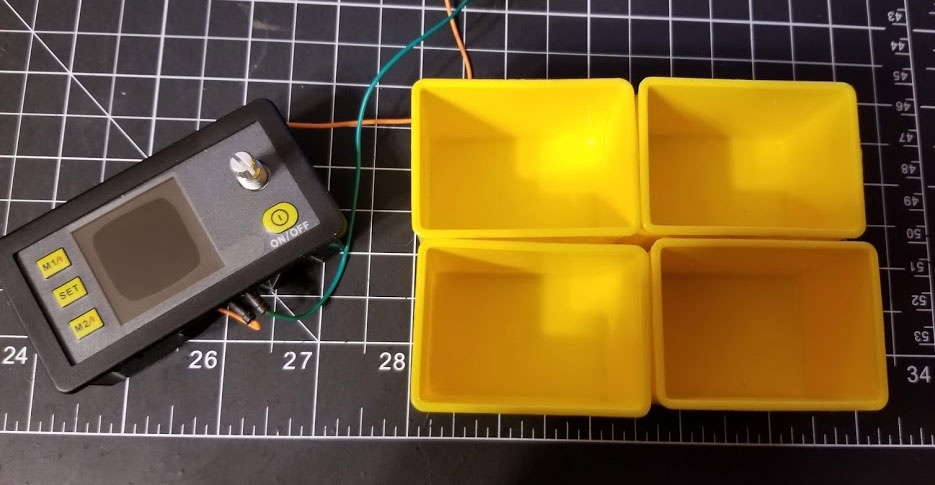

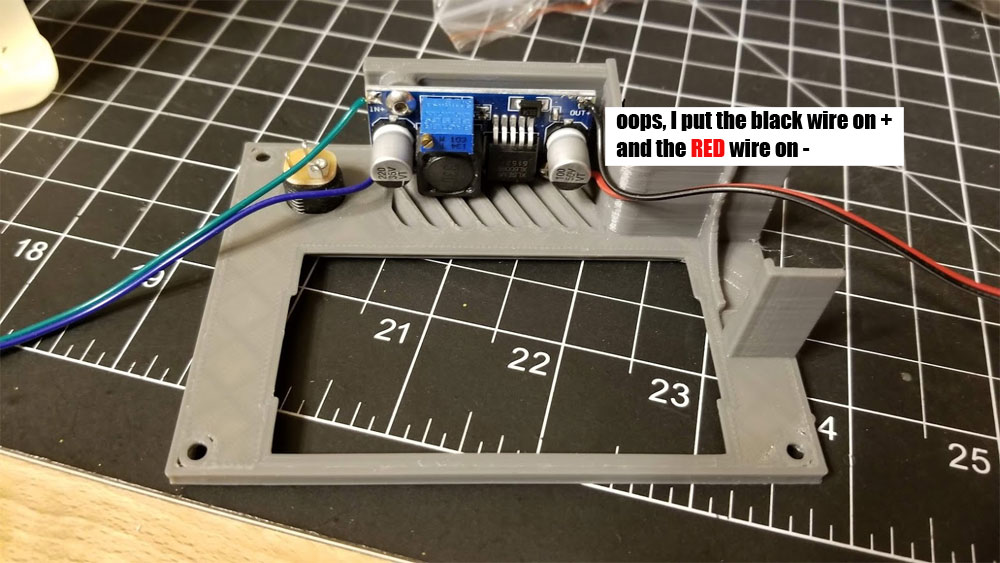

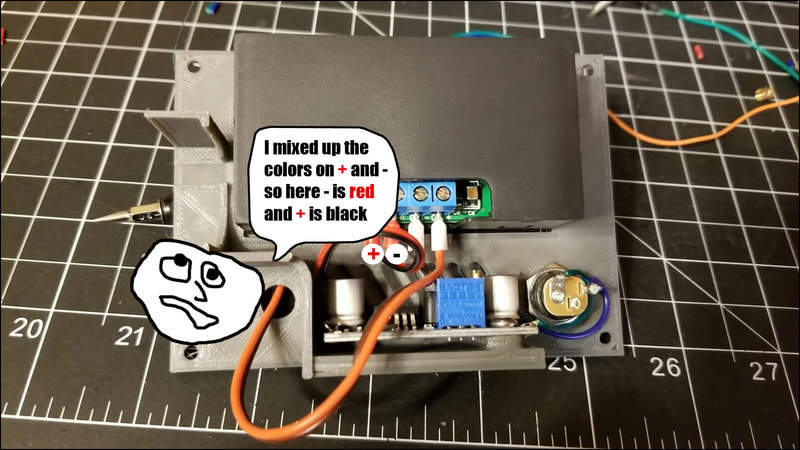

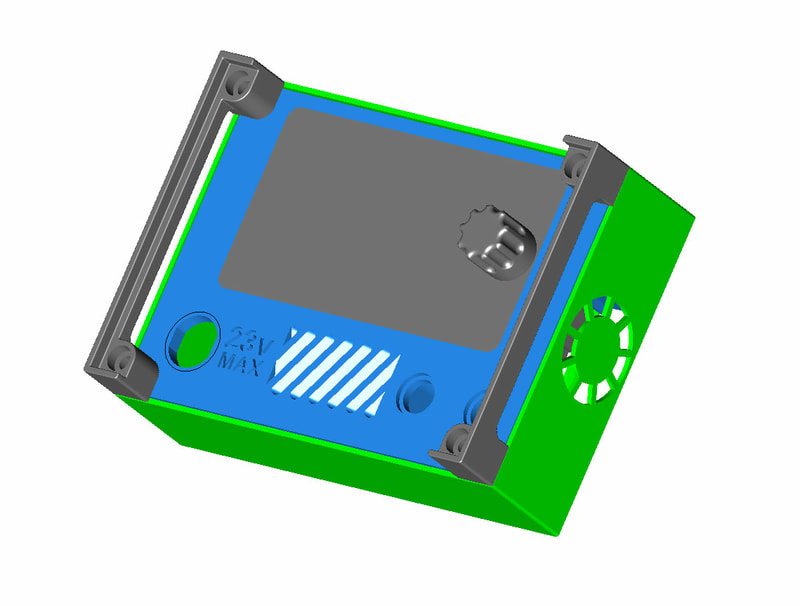

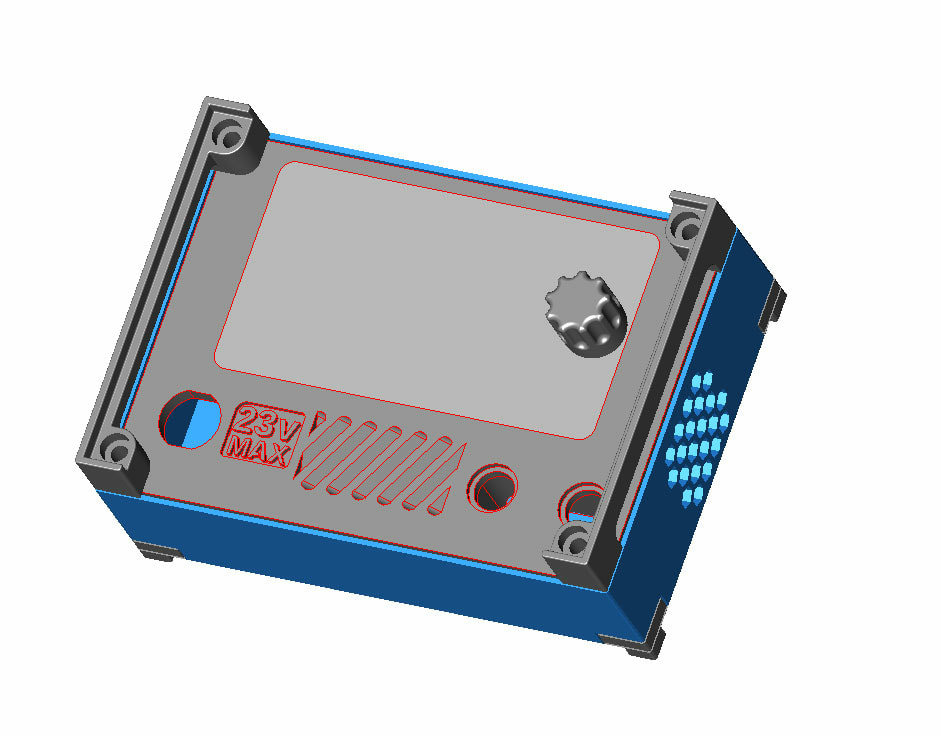

The solder fume extractor will use a 20x60mm fan and will be powered by a Li-Ion pack. The electronics are packed into a module which can be assembled outside the enclosure, then placed inside when everything checks out. It will include a USB battery charger and protection circuit for the Li-ion cell, a boost converter for the 12v fan and a display for the battery level which will be controlled with a momentary switch. Getting that stuff to all work was the largest chunk of work and wasted some time and filament getting things right, but it's better than printing the whole mess to find out one switch does not work. I also now have some useful modules to use in other projects.

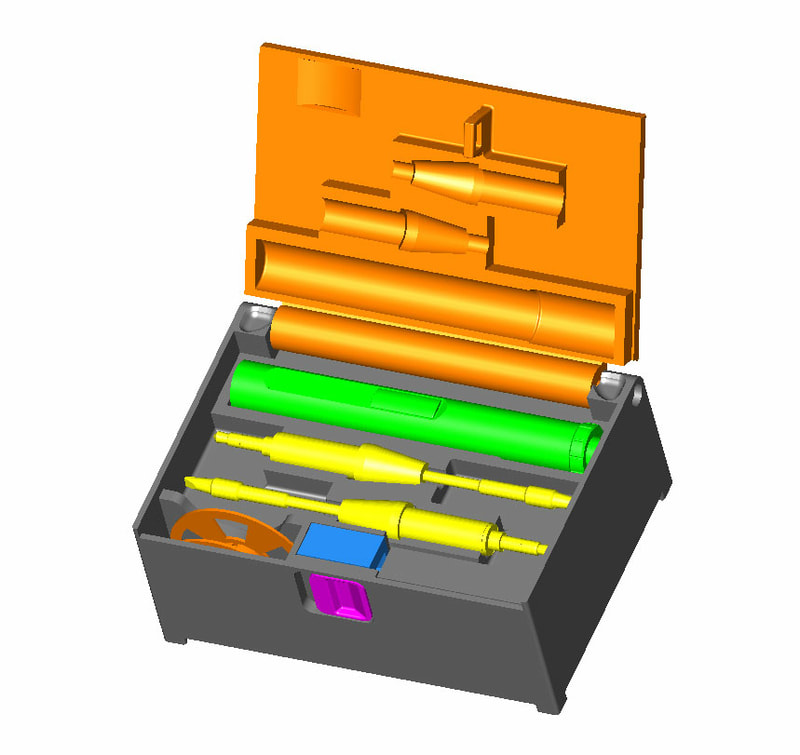

The TS-80 case will also hold a power bank, specifically this one from Anker. That power bank is only 10k mAh, but it does work with the TS-80 well enough that I can get some usage from it before it dips too low to use. The primary thing it has going for it is the QC 3.0 and the size which make it ideal for fitting in my Stanley Case.

It will probably be a couple more weeks for this stuff to get finalized and posted up. The power supply is posted here.

Update - the TS-80 case is posted here.

RSS Feed

RSS Feed