And this is a great video on how to deal with a really out of alignment X-gantry (after seeing it, I would do this on my printer if I was building it again) - in fact just stop reading the stuff below and check out the video below:

Will leave the original post in case it may help - but please see the above videos (or at least the EdgeOfTech video) which are better and clearer guides:

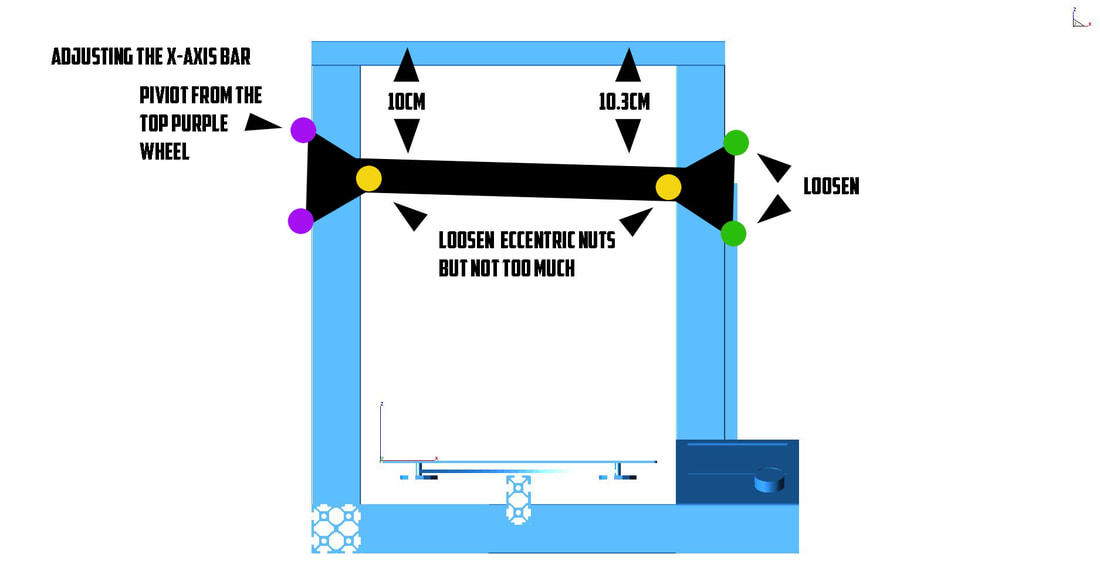

After getting the frame square, I noticed that the X-Axis 2020 extrusion was not parallel to the top 2020 extrusion on the frame. When I measured it was about 3-4mm lower on the right side. I just considered it to be an arm on a pivot point and adjusted it accordingly. (update 6/16/2022) In the process below, the idea is to use the eccentric nuts, and also the bit of slop in the holes for the other wheels, to first bring the x-axis parallel with the top bar and then snug up the outside wheels first by pushing them in while tightening. It can be a bit tricky to push the outside wheels in while tightening them, but if the slack can be removed from the non-adjustable wheels, the eccentric nuts will have more adjustment range, and won't need to push excessively from the inside of the frame to tighten all the wheels up (which would seem to also affect the geometry possibly). Below is the process I used to fix that - from memory so I may have left something out, but this is the basic process:

1. Unplug the printer and then disconnected the Z-Axis stepper (this will keep any back EMF from damaging the board or stepper drivers).

2. Rotated the Z-Axis coupler until there was 10CM between X-Axis bar and top of the printer on the left side (didn't matter which side i set to 10CM, it is just for reference).

3. Noted the measurement on both the left and right side, measured from the 2020 extrusion on the X-Axis bar to the 2020 extrusion on the top frame (not between mounting brackets).

4. Write the measurements down and noted which way the X-Axis bar is tilted. In my case the right side is sagging (low).

5. Loosened the yellow wheels by turning the eccentric nuts, only loosened them enough so they turned freely. The eccentric nuts can be turned either way, so just need to adjust a bit and feel if the wheels are getting lose or tight, it should not take more than 1/2 turn to see some change. See pics below for more info on the eccentric nuts.

6. Loosened the wheels in green in the pic below, and if I could not then adjust the X-Axis bar, I would have loosened the bottom purple wheel also (but I did not need to).

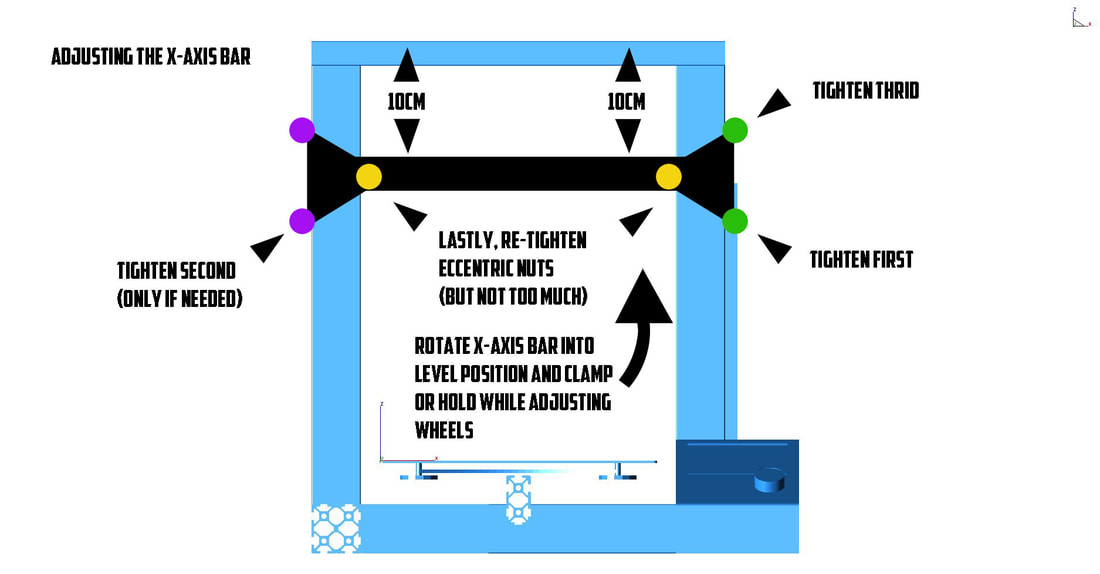

7. lifted the right side of the X-Axis bar so it was level, if possible clamp it here or just hold it - both sides should now measure the same 10CM distance from the top 2020 extrusion (X-Axis bar is now parallel to the top 2020 extrusion).

8. Tighten the bottom green wheel on the right side, then the bottom purple wheel on the left side (if loosened), and then the top green wheel on the right side. These outside wheels need to be pushed snug to the frame while tightening since there is just a bit of slack in the mounting holes that will allow that. It may be necessary to "split the difference" when taking up this slack between the left and right side outside wheels.

9. Re-adjust the yellow eccentric wheels to snug them down, I adjusted them so I could turn them with my fingers but not easily.

10. Verify all wheels are tightened and I was able to turn them using my fingers (but again they were not easily turned).

11. Re-measure the parallelness of the X-Axis bar and the top 2020 extrusion by repeating #2, then make any adjustments again.

12. Once done, re-connect the Z-Axis stepper and verify that all the steppers and end stops remain connected.

RSS Feed

RSS Feed