I recently had to remove the stock hot end (again) from my X1C to try and clear a nozzle issue which I think was causing poor quality prints (that is still up in the air), and while I was at it I broke the thermistor wires (oops, but that is on me). The thermistor wires on these things are super fragile, and even when they don't just fall apart, the wires can be pulled out of the connector very easily. That is just to say, be careful and maybe grab some spares.

But my fat fingers breaking thermistor wires is not what this post is about, it's about the after market Bambu Hot Ends. There are two versions of these, which I am aware of, and both have their purported pluses and minuses. I bought the "2.0" version, which has a more robust connection between the heat tube and the heat sink. The link by the way is for reference, they are available for around 10 bucks from China. The V2 probably is the one to get, since bent heat tubes can happen. However the one caution with the V2.0 hotend (which I have read about), is to evenly tighten the screws on the metal mount that attaches to the heat sink. That will avoid having the hot end tilt to one side due to uneven tightening of the screws.

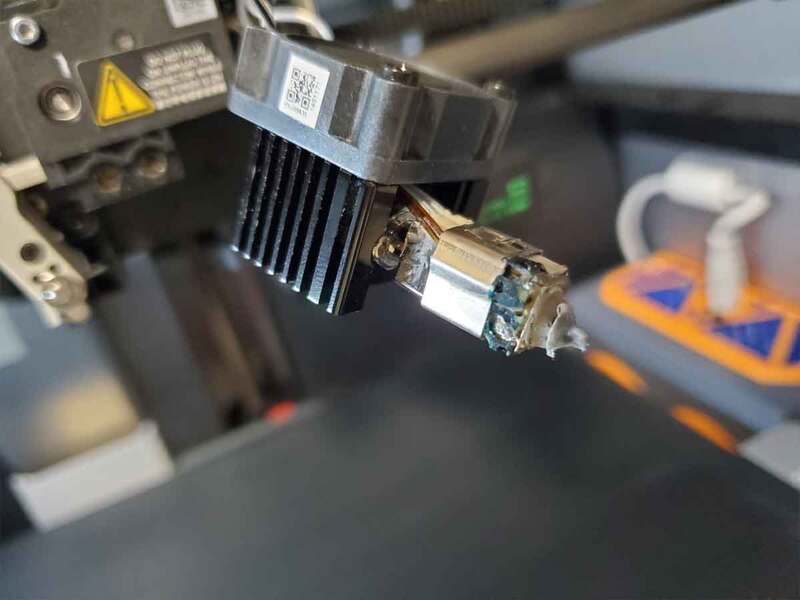

I set up my V2.0 hot end, and tightened down a new nozzle in it, so I was interested to see what it would do. What I got was a bunch of boogers. I cleaned the nozzle several times, and thought maybe the wiper was not doing as good a job on the non OEM nozzle. But after a couple prints had blobs deposited in various locations thru the printing, I pulled the V2.0 hotend off to check it. What I found was a classic problem with 3D printing nozzles - that is failure to hot tighten the nozzle. I had torqued the new nozzle down pretty well when I installed it, but I got just a smidge extra from turning from it when it was at 250°C (after cleaning the plastic off). I should have expected that to happen (it was in the back of my mind since I started to see blobs), since I would never try installing a normal nozzle without hot tightening it. And yep, the aftermarket hotends are more like a normal nozzle, so that's also on me. It may also be however, that my aftermarket nozzle or hot end may be faulty in some way, so I will update if hot tightening helped much.

But it does lead me to think that these aftermarket nozzles are a niche item, and so I would not recommend anyone who is not needing whatever extra edge they provide, since they also come with downsides. If you run a print farm and burn through nozzles, or run some exotic material that may work better with the aftermarket nozzles, sure, go for it (but you also probably have a ton more experience points that I do anyway). But for a person who does printing casually, and maybe just wants a more trouble free experience, I'd say stick with the stock hot ends. The Bambu OEM hotends are reasonably priced, and well made (and if you don't run abrasive materials they are gonna be more hassle free). The stock nozzles by the way are pressed into the heat block, so they should not leak unless they are faulty (which seems pretty rare based on my casual monitoring of reddit). In any case, hot tighten the suckers if you use these aftermarket hotends, it can save some failed prints - and frustration.

I put the old OEM 0.4mm Bambu nozzle back on, which is what my printer shipped with. I checked the wear closely under a microscope and it's looking good. This is the same nozzle which started the fun since it was poorly printing, but I'm gonna give it another shot before I swap it out. With the stock nozzle back on, the k values have dropped just a tad which is interesting as well (though the aftermarket nozzle was leaking so that probably accounts for why they dropped when moving back to the OEM). The OEM 0.4mm nozzle I am running now, has had a cold pull done on it already, and I will do it again once it's purged out.

RSS Feed

RSS Feed