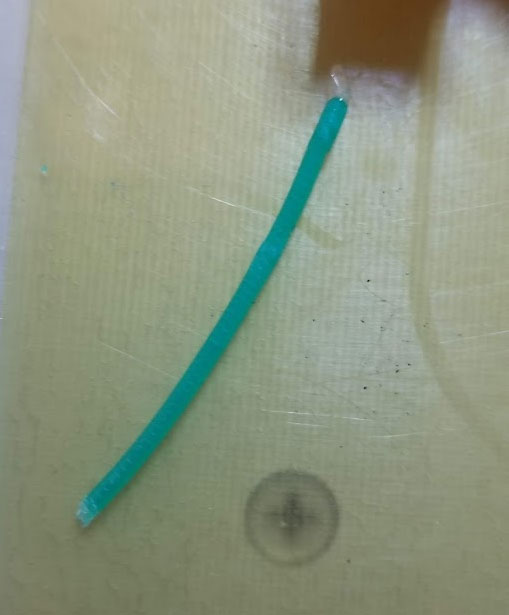

First the Ender 3 with the Titan Aero clogged up and ground the filament down. This has not happened in some time, but looking at the inside, it was full of ground up green filament and not much else, so that seems to indicate that the problem just started. I cleaned out the crap, and noticed that the filament was pretty well jammed in the hot end which seems to indicate heat creep. This green filament is PLA, but it is suggested to run it at 235 which is closer to ABS. I have however run this same filament many times in the Ender 3 without issue. My retraction is very low (0.4mm) so it is probably not that. It's a puzzle to me right now what caused this.

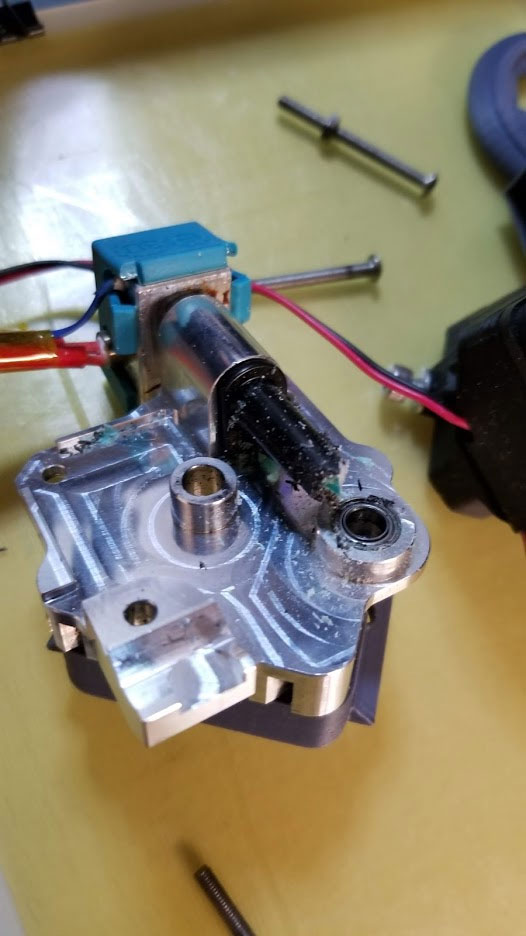

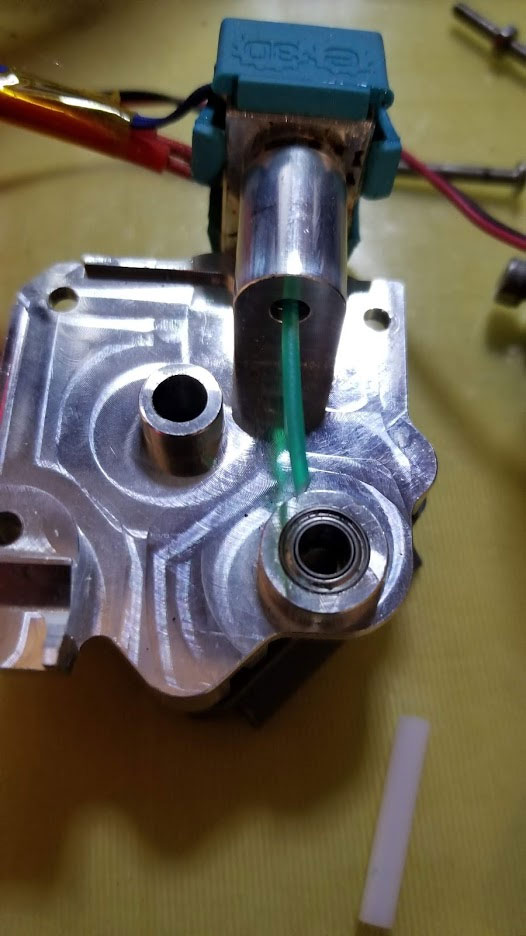

So the next clog was my delta printer which has a V5 hot end. I have been wanting to swap it out for a long time, but just don't have the time right now. This one was well and truly clogged, I tried all the regular tricks, atomic pull (oops, broke the filament before the clog), stuck those tiny needles up the nozzle - they just hit a solid jam several mm in. I removed the nozzle to see if I could possibly push the clog out from the top or bottom. That last one was successful, but I did not have anything that was really designed for knocking out a clog like this. The clog was above the heat creep zone where heating the hot end does not loosen it and it was pretty well stuck. I ended up using a 1/16" drill bit (my last one), which I chucked in my cordless drill for some extra grip. I carefully lined it up and inserted it into the heat break tube from the bottom (with the nozzle removed), then heated the hot end up and when it was at temperature, I started to push the drill bit up through the heat break which finally dislodged the clog. I was then able to pull out the approximately 5mm segment of PLA that was causing the problems from the top of the hot end using some tweezers. I need to grab some more 1/16" bits since they may come in handy.

The most likely reason for the clog on the delta was some stop gcode which did a 1mm retract followed by a 5mm retract after finishing a job. My retraction on this printer is 3mm so I suspect that the extra retractions at the end of a print were sucking molten PLA up into the top of the heat break tube which then formed the clog. Supporting that possibility is that the prior print completed, but it was clogged when I tried to run the next print. The Delta had been down for a while and I did not think there was any issue with the old start/stop gcode I had been using, but I hope removing the retractions from the stop gcode fixes the problem.

Well nope...the delta still has clogging problems, and this morning, after clearing one clog and pushing some filament throug by hand it immediately clogged again. Just about broke my hand pulling this clog out (and yep it was pre-heated), and the bowden couplers had some sort of death grip on the PTFE tube, will need to swap them out for something that will release as well as hold the bowden tube (which also ended up pretty messed up after the ordeal of trying to get that little plug or melted PLA out). So the bowden couplers and PTFE tube were collateral damage but at least for the couplers, they were probably bad anyway. I think the next step is a full tear apart of the V5 hot end to see what the deal is with this gap that is allowing a plug to form. Another weekend half shot thanks to printer problems, which I think is my cue to give up for a bit on this for a while. Will figure it out, just not today.

Update - Jan 27, 2019

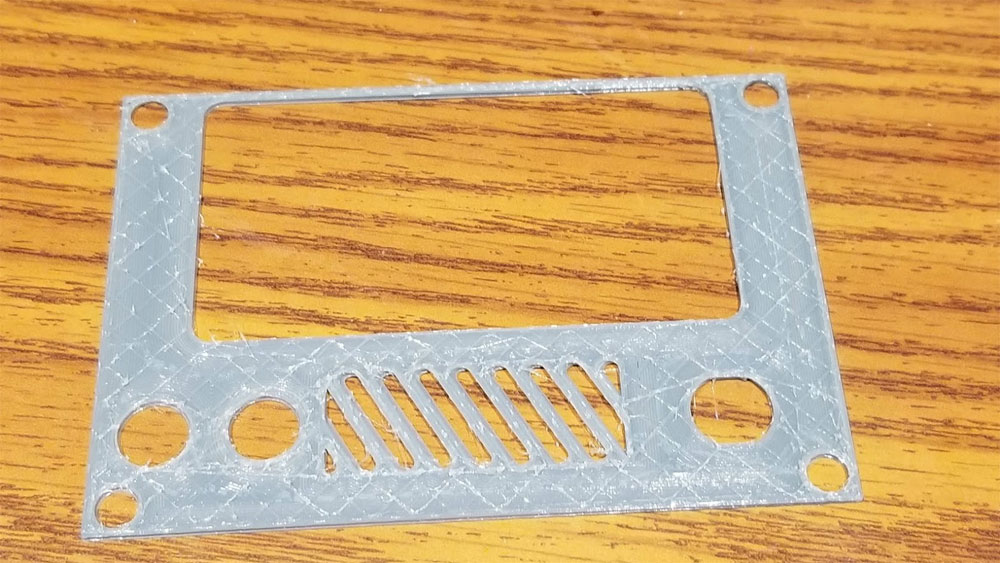

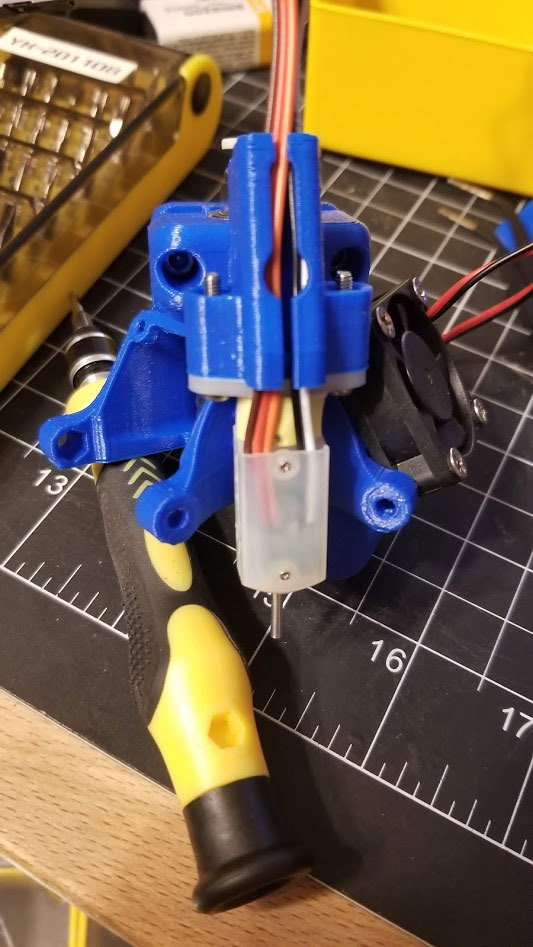

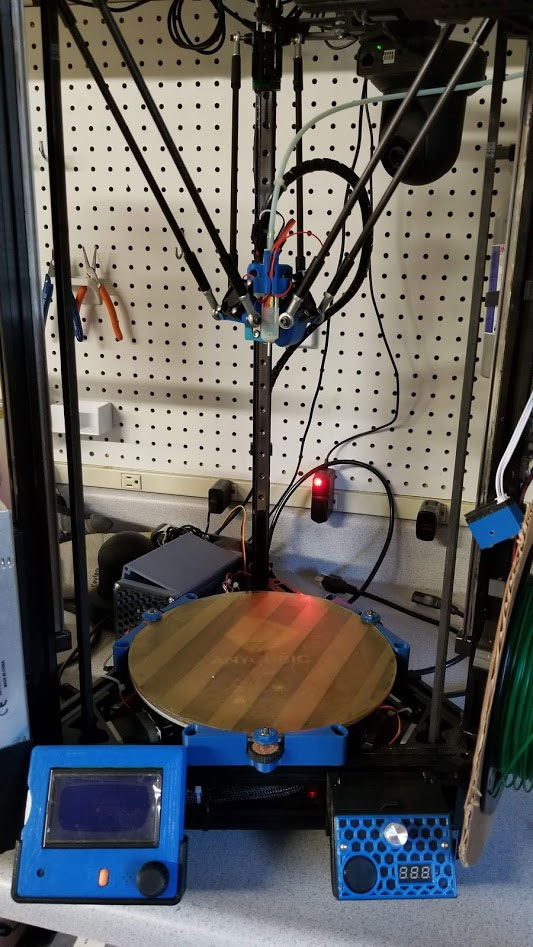

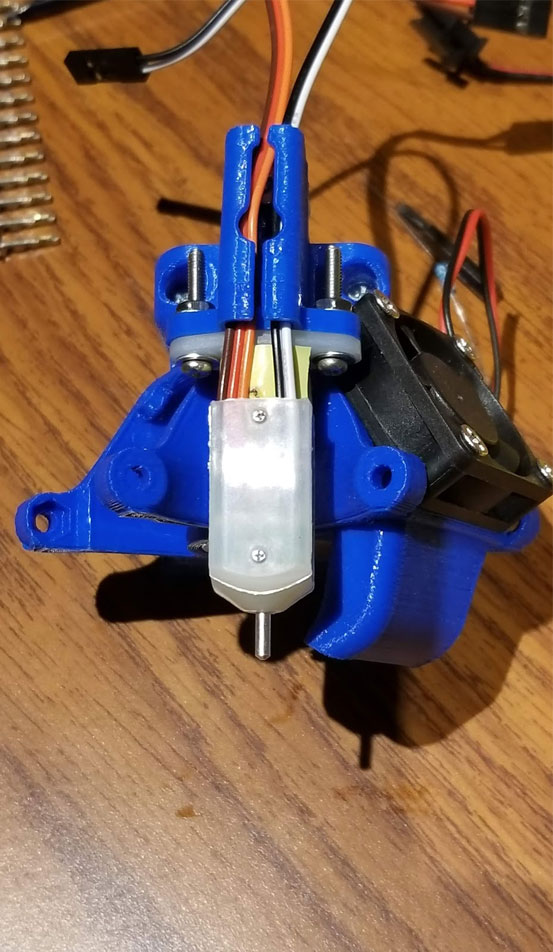

The Delta had more problems with clogging and I found the problem, which was a loose wire to the hot end cooling fan. It was making enough contact that it would come on when it was stationary, but as it moved it would become intermittent. However I am not going to swap the original hot end with the one below, which sports a custom touch probe mount (27mm offset). I am hopeful that I can get this working in the next week when I get some more time since I have to also update the firmware and wire it up (most of that is done, but I have not installed it yet).

RSS Feed

RSS Feed