But there is a fix, provided by TinyMachines (Updated Link 10/20/2020 - https://tinymachines3d.com/products/creality-10s-pro-modified-extruder-lever-1?_pos=8&_sid=06017859e&_ss=r ).

They will mill out the lever and provide some bronze washers for $12.50 (plus shipping). It is cheaper to get a new dual gear extruder from Amazon, but it looks like many of those will probably have the same trouble in time, so this is a better fix if the idea is to keep it stock.

There are certainly better options for direct drive extruders, but right now I just want it working again and don't have the time to spend installing a Bondtech of Titan (which require firmware and vref changes). Not sure what the turnaround time is on it though.

And here's a great video which explains the fix from Liqui-Dirt 3D.

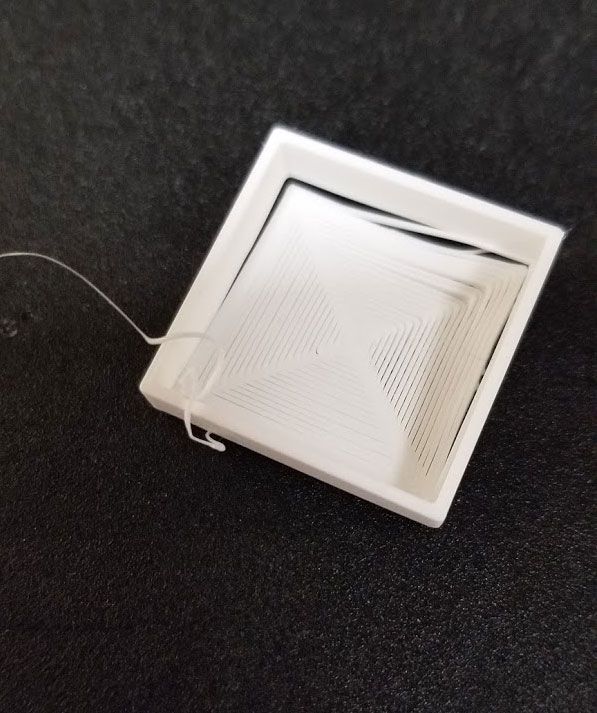

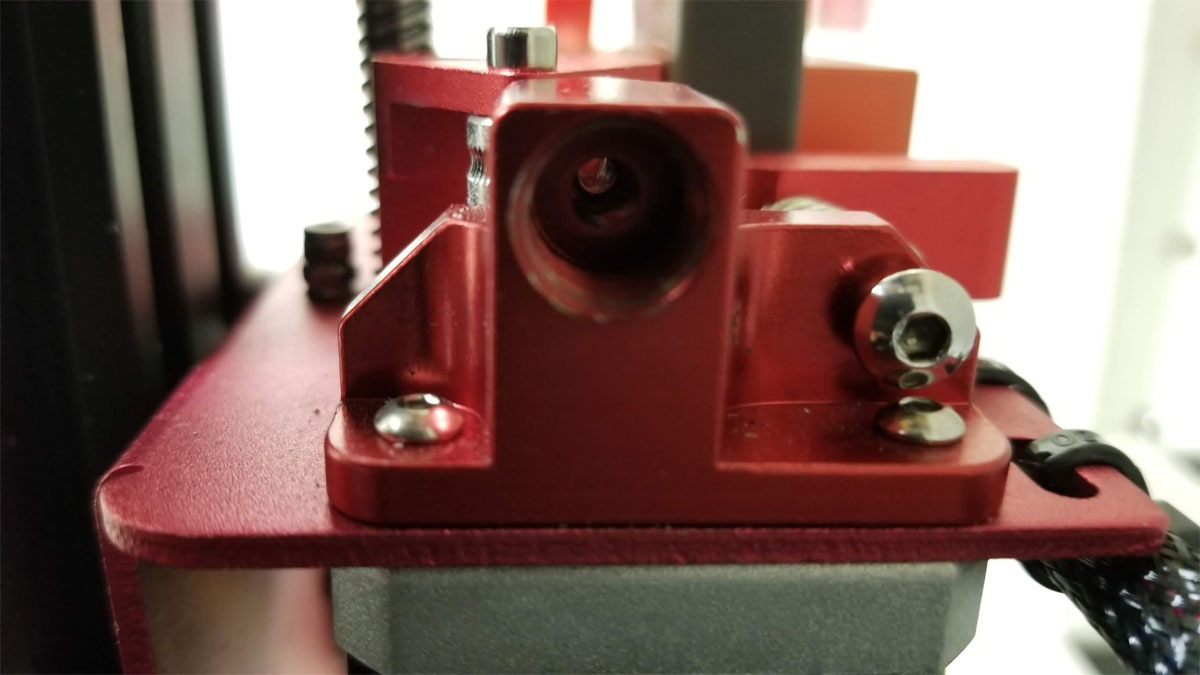

Update #2 (10/20/2020): Updated the link (thanks Sam K) and found that they are now selling the replacement level which includes the fix. Also, I found the original issue was due to the bowden tube not being fully inserted into the extruder. The extruder has a smaller diameter pocket designed for the bowden to extend in several mm further than the end of the coupler (see the pic below). Because this pocket is not beveled and is about the same diameter as the bowden it is difficult to get it to extend all the way into the pocket (gets caught on the tip of the bowden tube). I have trimmed a slight bevel to the outside of the tube which helps somewhat but its still a bit of trial and error. If there is a gap then it can also cause an unusual clog which cannot be removed without removing the coupler from the extruder (makes a pigtail of wound filament in the gap). If the bowden is fully inserted however there should be no problems.

RSS Feed

RSS Feed