For my new Bambu X1C, I've designed a small HEPA filter cover which is slapped on the back of the printer, and held on using a bunch of magnets. I just installed it yesterday and have not tested it, but it looks cool at least. This is going to be a temporary solution for my printer though, since I will eventually add a duct system similar to my current enclosure setup.

The plan for the next iteration will be to run a duct from the outlet on the back of the X1C, with a booster fan (6038 12V) inline, which will vent out a doggie door (through a printed cover). The booster fan will use a 4 wire PWM fan, and I'm planning to design a remote PWM controller, with a potentiometer to control the speed. I think the booster fan will be needed, since there is going to be several feet of hose, and the small fan on the back of the printer won't cut it. I'm also considering a small circular filter in the booster fan housing, since I prefer to filter the air before sending it outside. I'm still waiting on parts to finalize that design, but I was able to use some of the earlier models from my current setup, which helped speed things along a bit. If the fan has enough power, then I think the newer design should be improved over what I'm using now, and more modular as well.

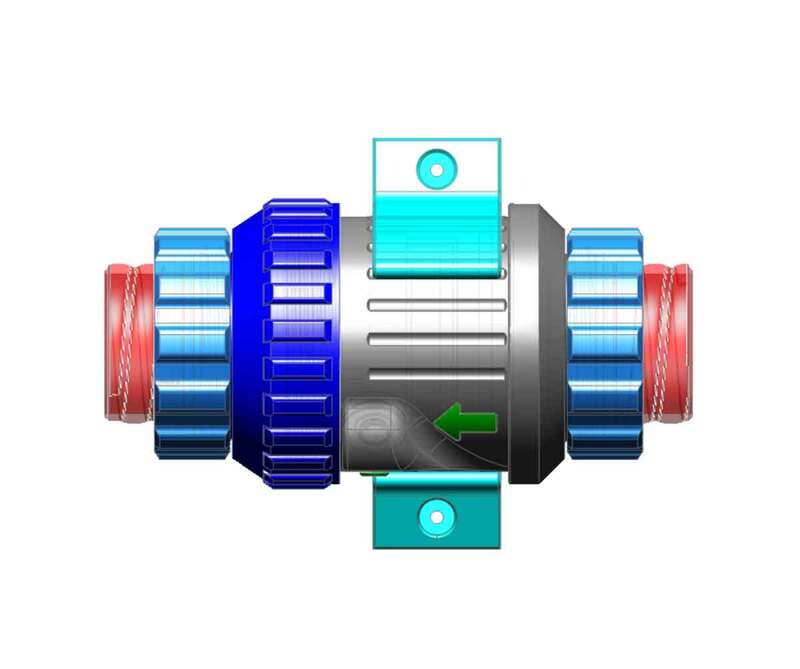

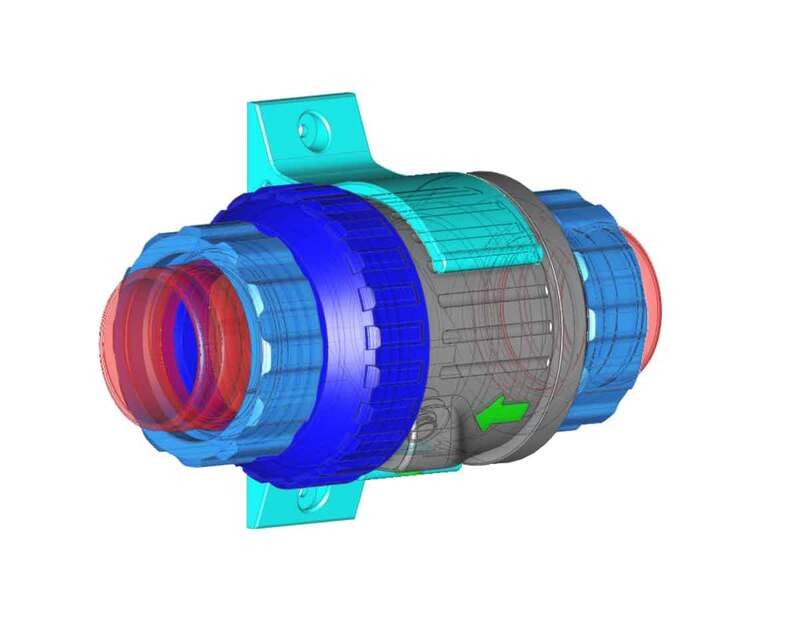

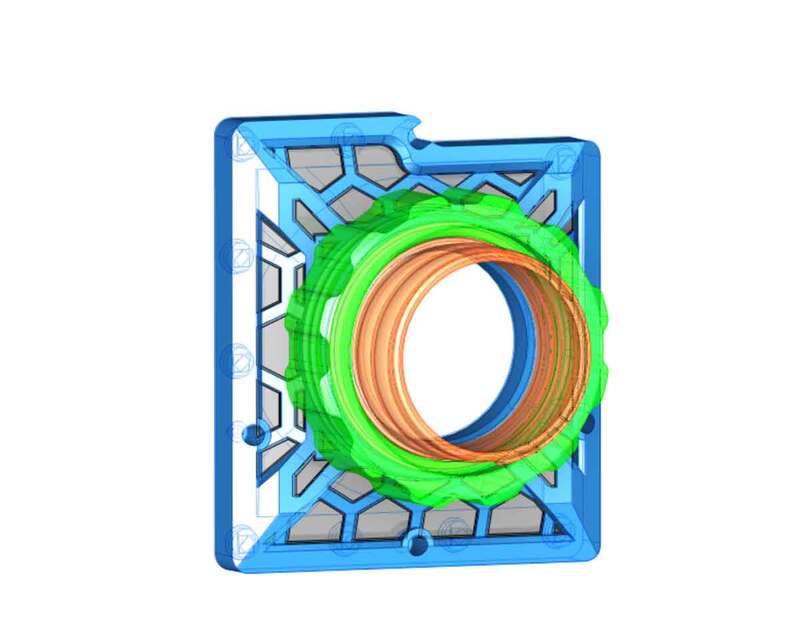

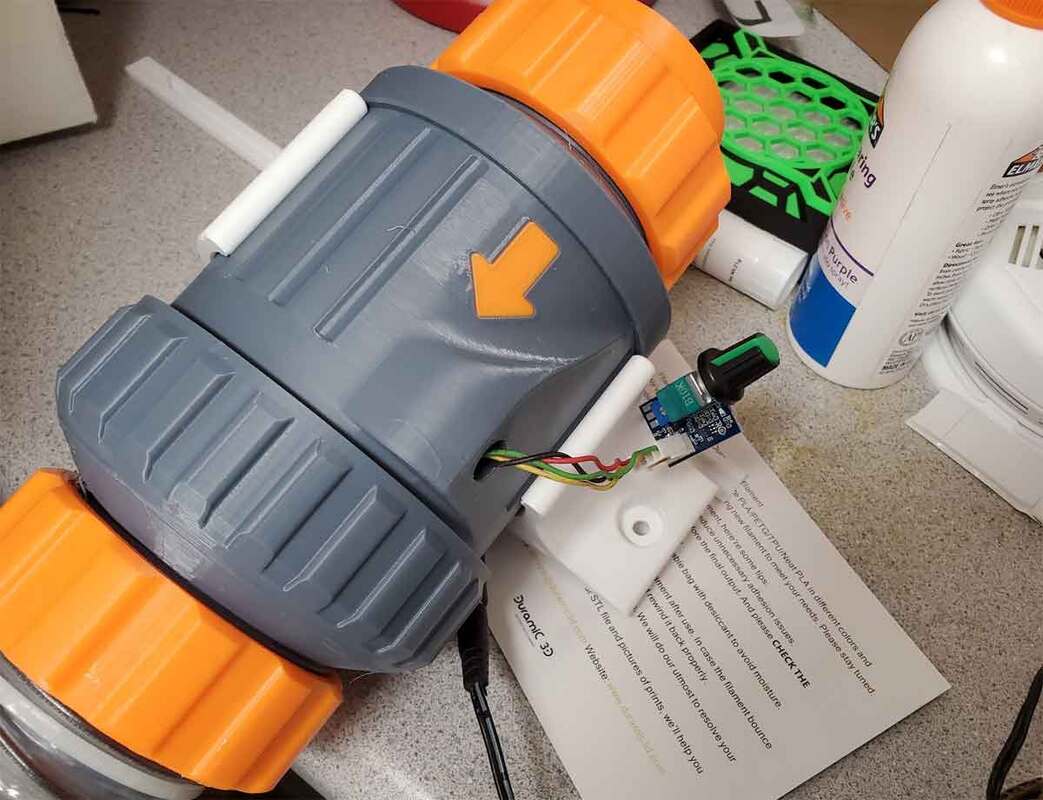

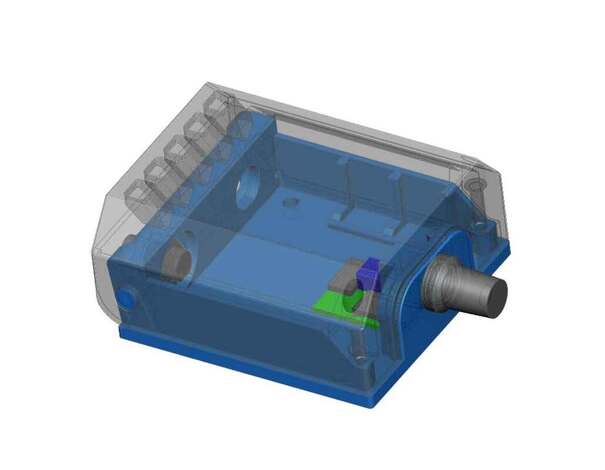

Below are some pics of the inline booster fan (with a filter), and the last pic is the coupler which will connect the hose to the printer. Although they look complete, I need the parts to finalize the models.

I found that the design is mostly OK, however I may open up the holes for the hose collars just a bit, and remove the brass inserts for mounting the fan (since it should be a one time deal, there is no reason to use inserts really).

I'm printing the PWM enclosure now, and may post that as a separate design once I complete it. For the final wiring configuration, I decided to go with some M8 aircraft style connectors on the booster fan end, and a M12 cable gland on the PWM controller end. I want to be able to completely remove the hoses and cables from the booster fan module, so having removable connectors is necessary. I've ordered an M8 male 4 pin panel connector which is wired, and that will connect to the fan. I also ordered a 5m female M8 cable, which I will cut off at about 1-2m and use the cut end with the PWM controller (it will go into the controller using an M12 cable gland). It's a bit of an expense in cables, but I have had to deal with plenty of intermittent garbage connections in the past, and having a reliable (and pre-wired) connector will be worth the extra cost. The final design will have a couple different options though, including a simple M12 cable gland at both ends, which are pretty cheap. I will also need to redesign my doggie door outlet to accommodate two hoses.

I also made some small changes to the hose couplers, which make them easier to assemble. And finally, I'm working on a design to connect the duct to an unused doggie door, which will replace a similar setup on my current printer exhaust fan.

RSS Feed

RSS Feed