The CR10S Pro didn't disappear, it's only giving up it's throne for a couple days so I can use the ducted enclosure to test the CR6 SE.

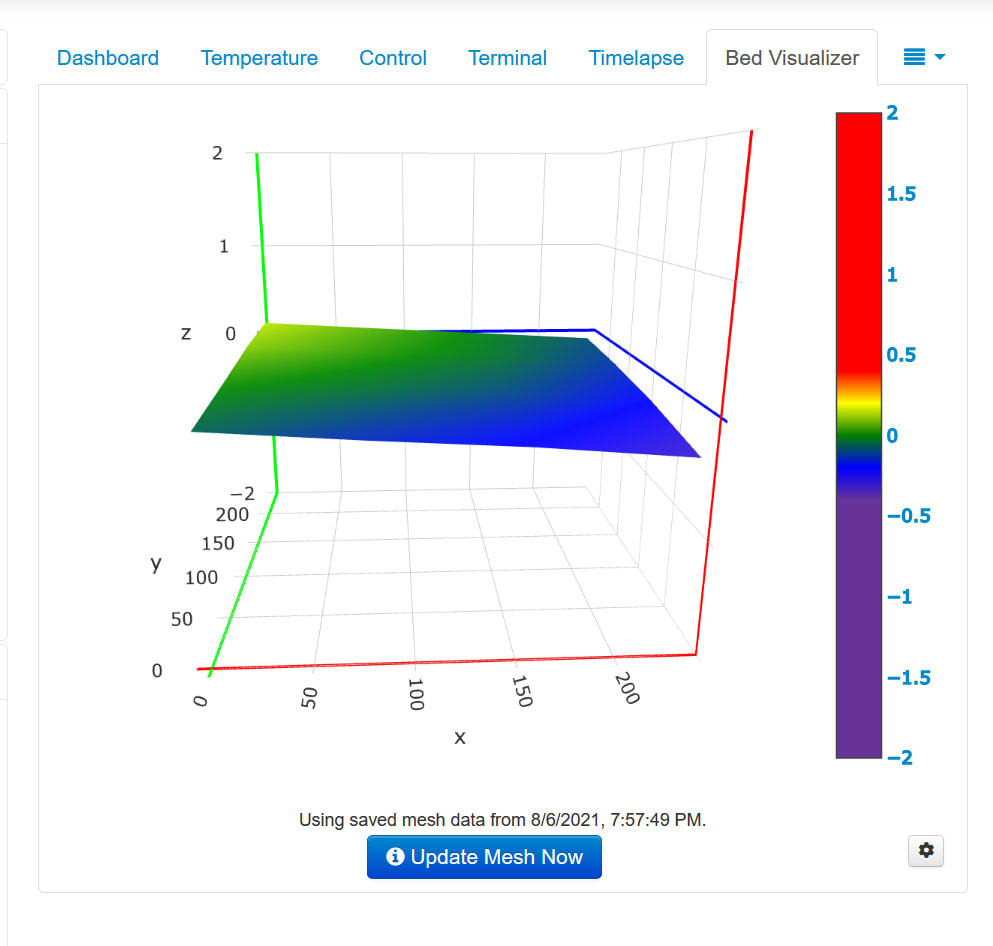

The CR10S Pro didn't disappear, it's only giving up it's throne for a couple days so I can use the ducted enclosure to test the CR6 SE. Then I ran an autolevel, and it looked pretty bad. Unfortunately with this printer there are no bed leveling screws (it is fixed). That may be fortunate depending on your point of view, but in this case I realized that the bed skew had to have something to do with the z screws being misconfigured, the bed itself or possibly even the frame (or all of these things). I first tightened down all the bed screws, which were only a bit loose so I did not expect they were an issue. I checked the gantry to bed measurement from both sides of the gantry and noted that the printer was about 1mm higher on the right side. I knew I would need to fix this but first something else was bugging me.

I had earlier noticed that the printer had a definite wobble when placed on a flat surface, so I loosened the eight large bolts which hold the sides on (not loose but just enough to allow me to adjust the frame). Then I set it on a flat surface and firmly pushed the opposing ends of the feel down until the wobble was gone. I also checked that the bolts holding the gantry frame to the base were tight (they were). Adjusting the base to take the wobble out did not take much force, but it made a big difference, and the printer now sits perfectly flat. Unfortunately these adjustments did not help much with the bed leveling.

This adjustment helped a bit and I could probably spend more time to get the level a bit better from left to right. But I think I will leave it here (even though I'd like to get it closer to level), since I think the auto-leveling can compensate for it. From the bed heat map there is still some diagonal problem going on.

I then checked the e-steps and found that it was off by 7mm over 100mm (I asked the printer for 100mm and it only extruded 93mm). I verified that the extruder was tight and not slipping, and re-ran it again to verify it was really off by 7mm.

The M503 output from the printer showed the following:

Recv: echo: M92 X80.00 Y80.00 Z400.00 E93.00

Since the original Esteps were 93 steps/mm, and my adjustment factor is 100mm requested / 93mm actual, I ended up with an new esteps value of 100 steps/mm - so I ran the following:

M92 E100.0

M500

I re-checked the e-steps and it was a perfect 100mm when requesting 100mm on the extruder. Its a puzzle why they are so far off, but the difference was repeatable and the fix was confirmed in a third test.

Finally I decided to print My Stoopid Test Cube and discovered what I suspect was the cause of the problems my buddy was having, which he attributed to the extruder. That is the z-offset was set too low. It was set as 0.2mm and I had to raise it to 0.4mm before my 0.2mm feeler gauge would slip between the nozzle and bed (I later dropped it to 0.30mm since adhesion was suffering). I'm still tweaking things before I try an larger print.

I can't help but throw in some thoughts on this printer. Aside from the inability to level the bed I really like the CR6 SE, the load cell auto leveling sensor is a great idea, and it looks solidly built. It's like a little CR10S Pro for ease of use and assembly. Unless there was a compelling reason like price or amazing speed or some leap in quality, I don't think I would buy another ender3 class printer though, they are just too limited in volume. For a beginner the CR6 SE may be or may not be a good printer. It has a lot of bells and whistles, but that also means it can be harder to fix. That said it's a good printer, this one just needs some love.

RSS Feed

RSS Feed