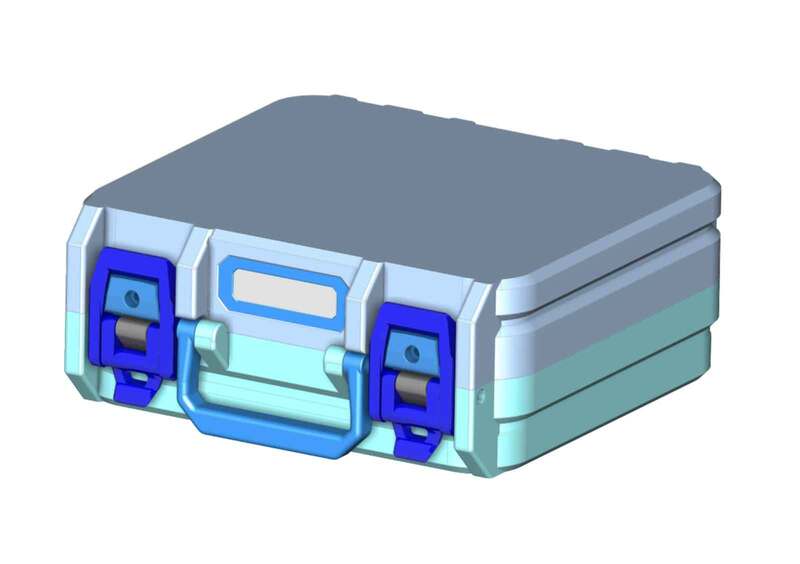

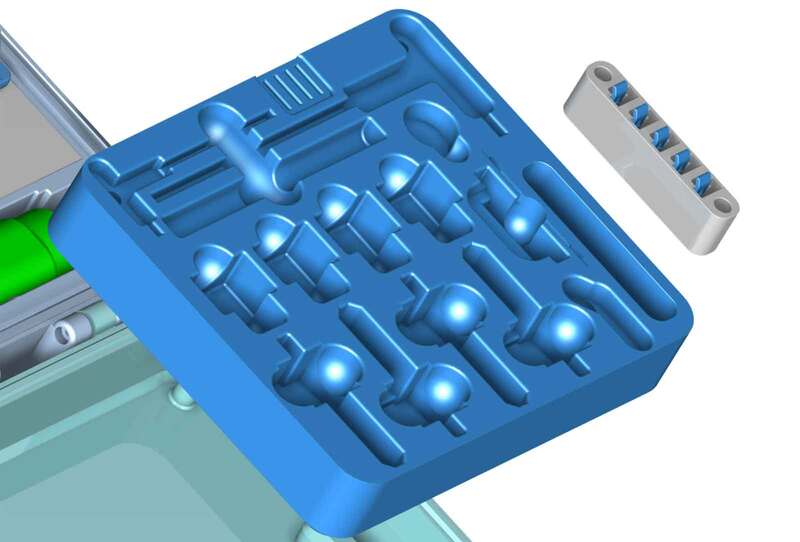

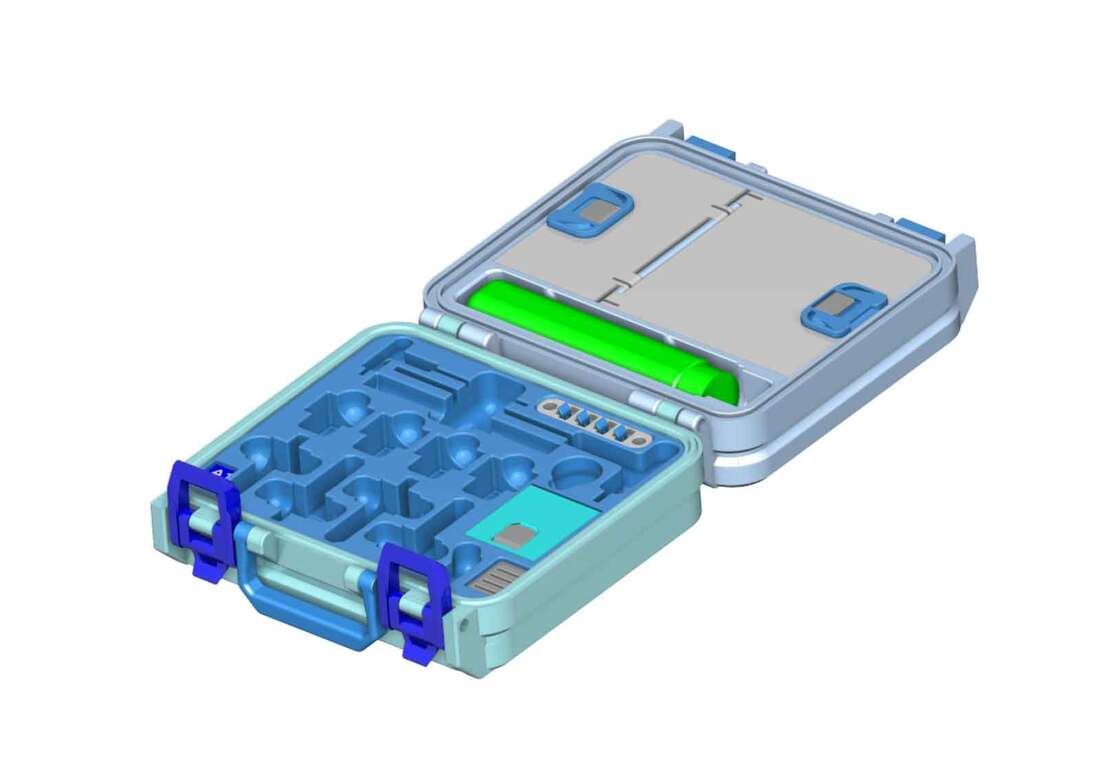

So after spending a few hours on the project, I think I have something that is close to done, however it will come with a warning, since I have no way to test that the spare parts will fit. I did test slice it however, and it will fit on an A1 Mini, even with a brim. Since this will take many hours to print, I may make some quicker printing test parts, or even attempt to make it modular, though I'm still thinking about that. Right now, there is no ETA right now for when this will get posted, but the design is close to done.

The design is a remix of my X1C/P1P/P1S spares case. Although I did not directly remix from the following designs below, I did use dimensions for the spare parts holders, as well as community feedback in order to make the pockets for all the tools. Since I used the dimensions from these models, I will credit them as remix sources when I post it (edit, I decided to credit these models in the description, instead of as remix sources, since the final design does not use these models as a source, only some dimensions were used in earlier revisions):

- Storage solution for A1 mini nozzle wiper (by Arni)

- A1 Accessories Tray V3 (by Redev22) which is a remix

- A1 Tool Box - Rugged (top remix - inlay remix) (by 3DMetalCave) - which is a remix of a remix

- A1 mini bracket for nozzle wiper - (dont forget to grab the nozzle brush) (by Kugelmann)

- PTFE Tube Remover V2.1 for the A1 (by R3DPanda)

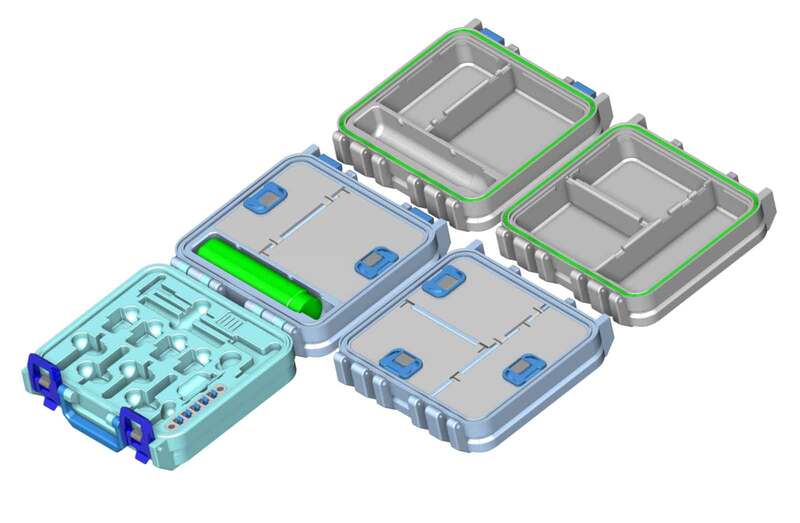

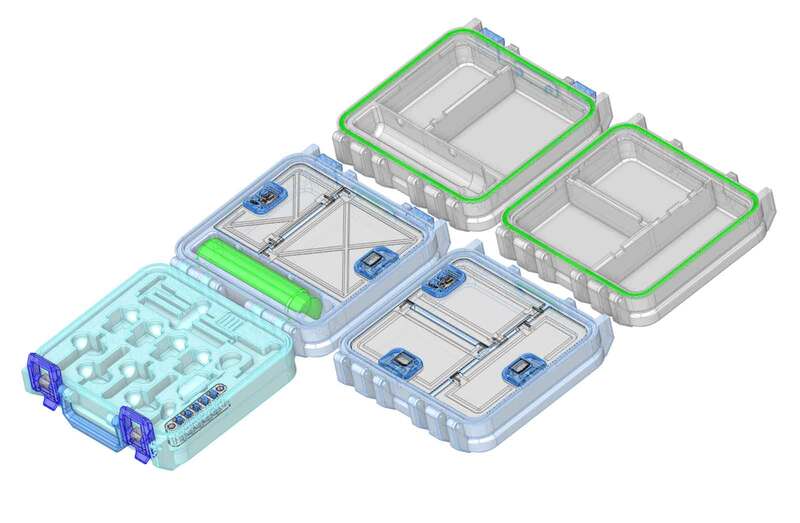

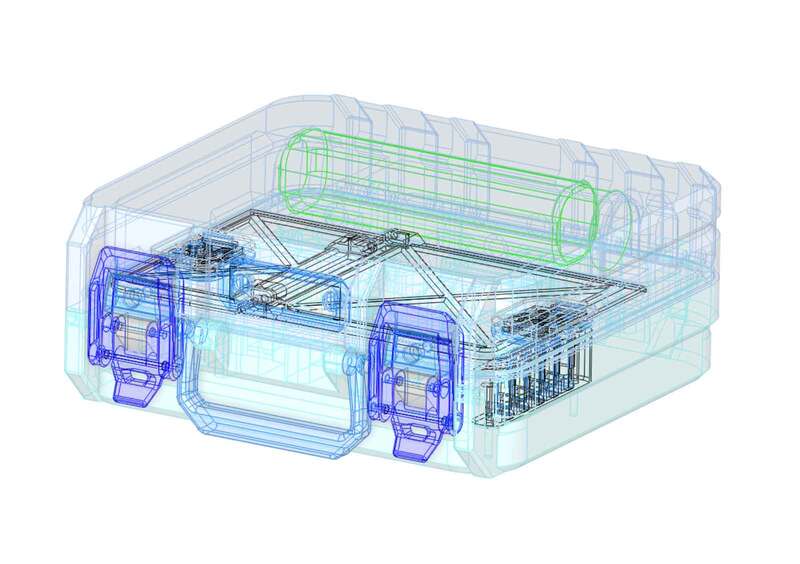

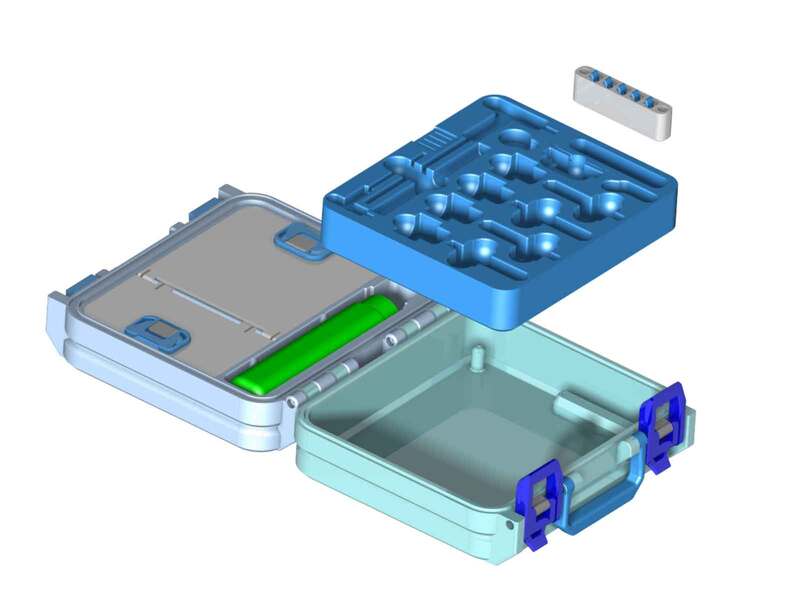

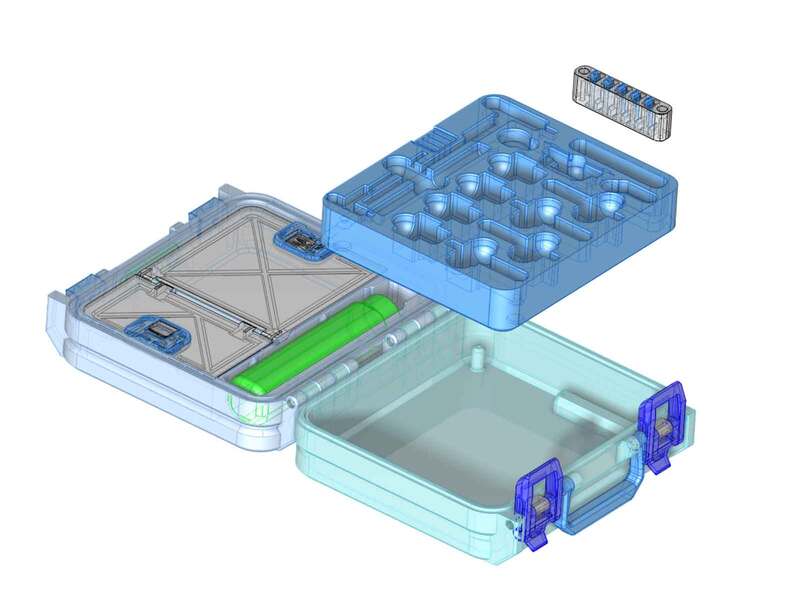

The tool box will have several options, including the following:

- TPU seal or no seal versions

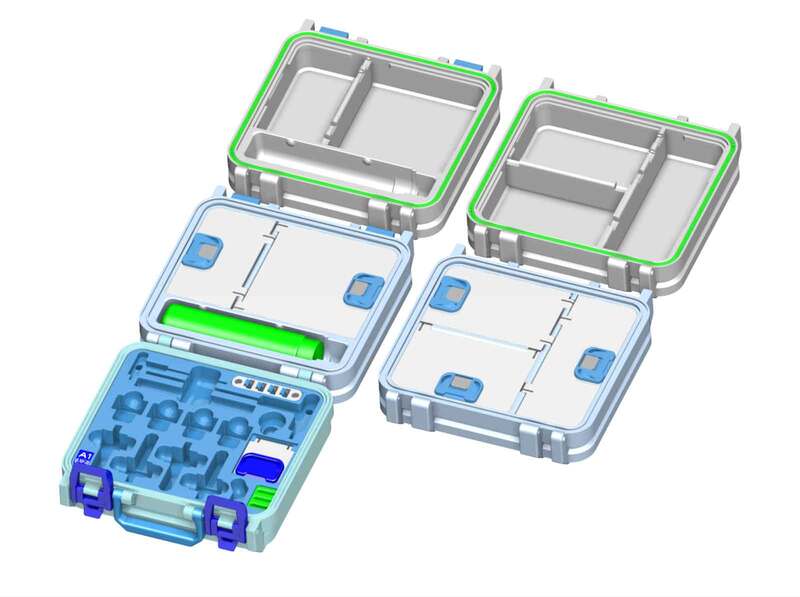

- A top with a liquid glue bottle holder and two compartments

- A top with three compartments (and no glue holder)

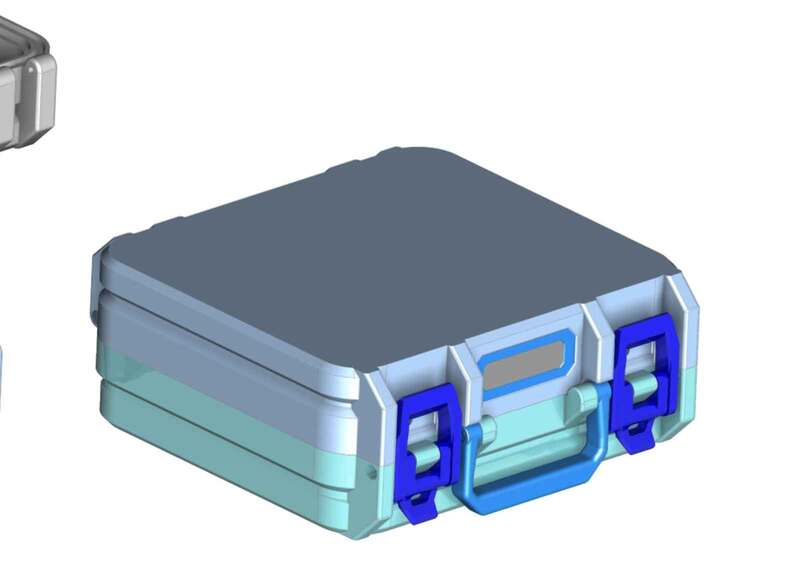

- A printed case label designed for 12mm P-Touch labels

- A blank case label, which can be customized using the slicer

- The hinge needs to be fixed, as designed, it would take a single long M3x45 screw, which is not common at all. I plan to simply it, so it can either use a couple shorter screws or maybe one M3x20 or M3x25 screw.

- The modular base mounts to the case using M3 screws and standoffs (on the case). Currently the screws used for this are different lengths, so I plan to try and consolidate them down to one or two lengths of screws. I also want to standardize the height of the case standoffs. Possibly with shorter case standoffs, the case insert could become a customizable module, and used for different projects.

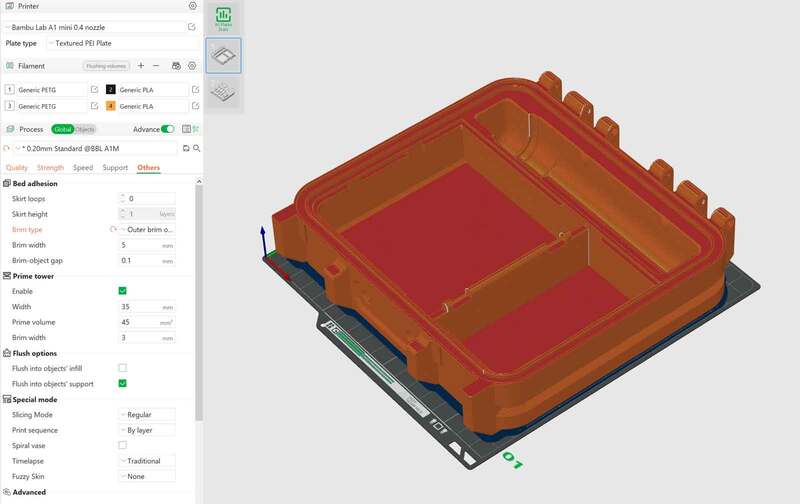

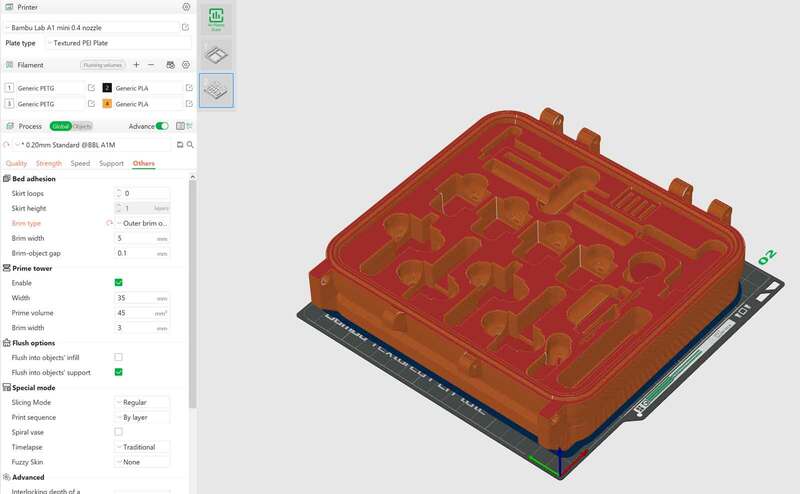

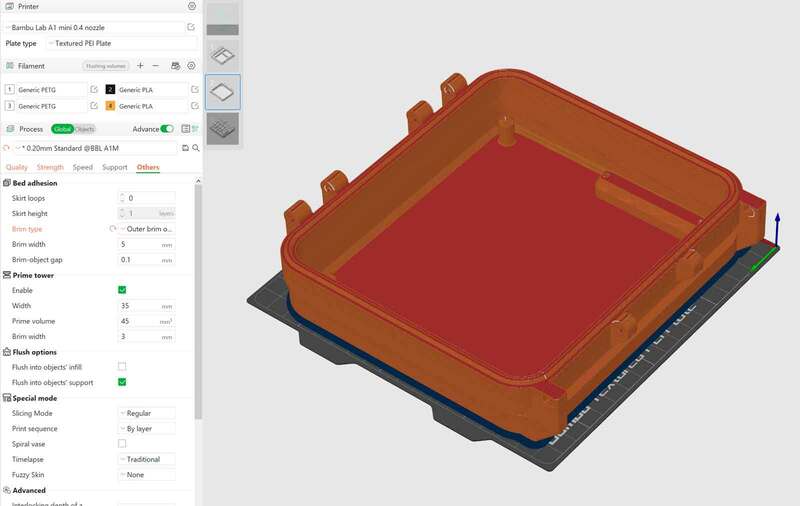

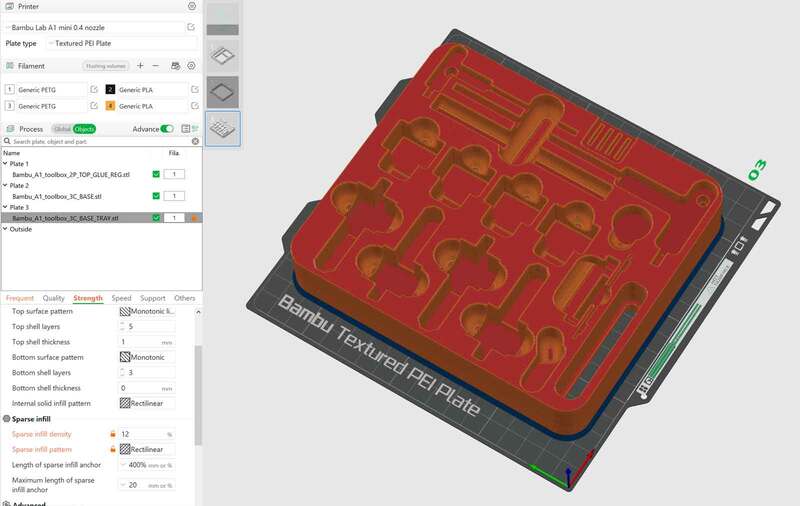

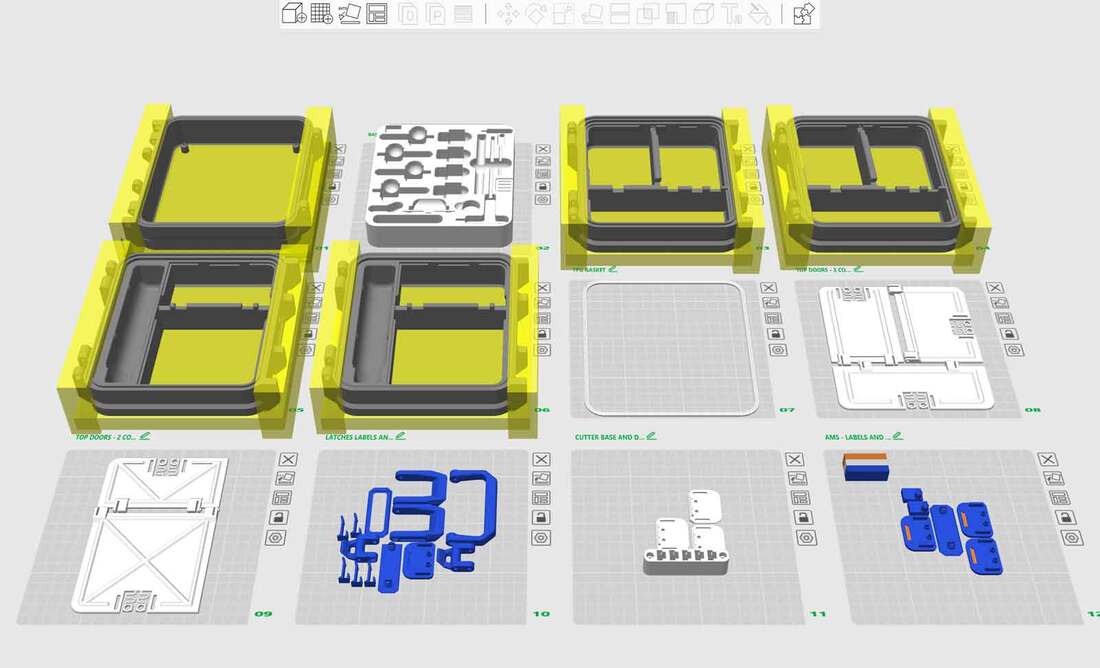

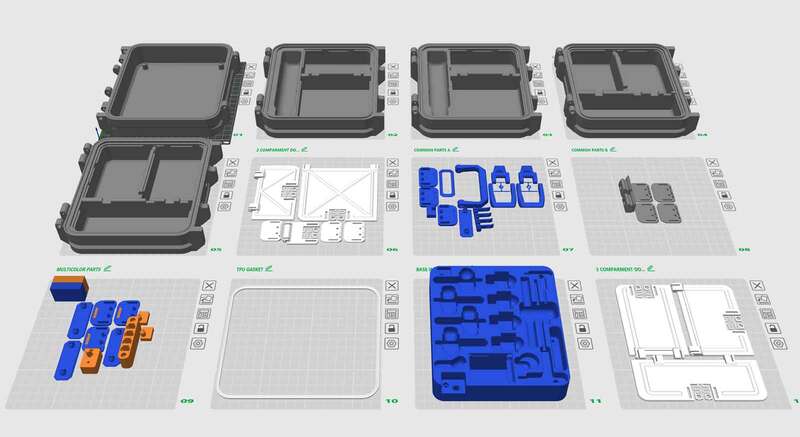

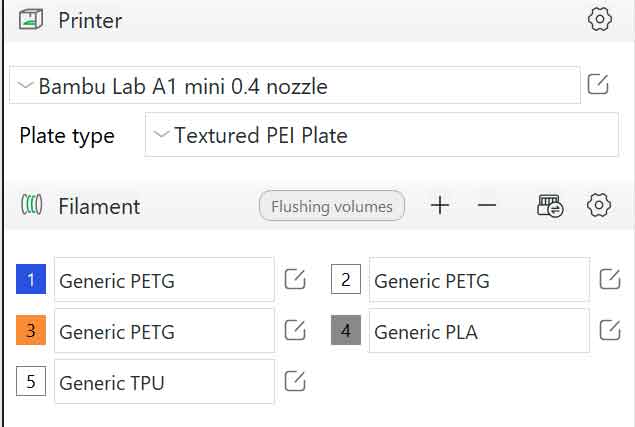

Update 2: The above fixes have been done, and the printer is running the base now. I set up 3MF profiles in Bambu Studio for the A1, A1 mini and my X1C, with modifiers and adaptive layers. There are also brims on the A1 and A1 mini for the larger parts, since those are open frame machines, and may need a bit more help with adhesion (vs an enclosed printer like the X1C). The image below shows the A1 Mini profile, and all the possible options for the lids, labels and AMS options. This is really a 6 to 8 plate print (the 2 extra plates are for the TPU gasket option and the multicolor parts option).

I'm running a test print now, which is one step closer to completing this one.

www.printables.com/model/861390-bambu-a1-and-a1-mini-spares-and-tool-case

I plan to upload it to MakerWorld later, once I get some feedback on the model.

https://www.printables.com/model/861390-bambu-a1-and-a1-mini-spares-and-tool-case

RSS Feed

RSS Feed