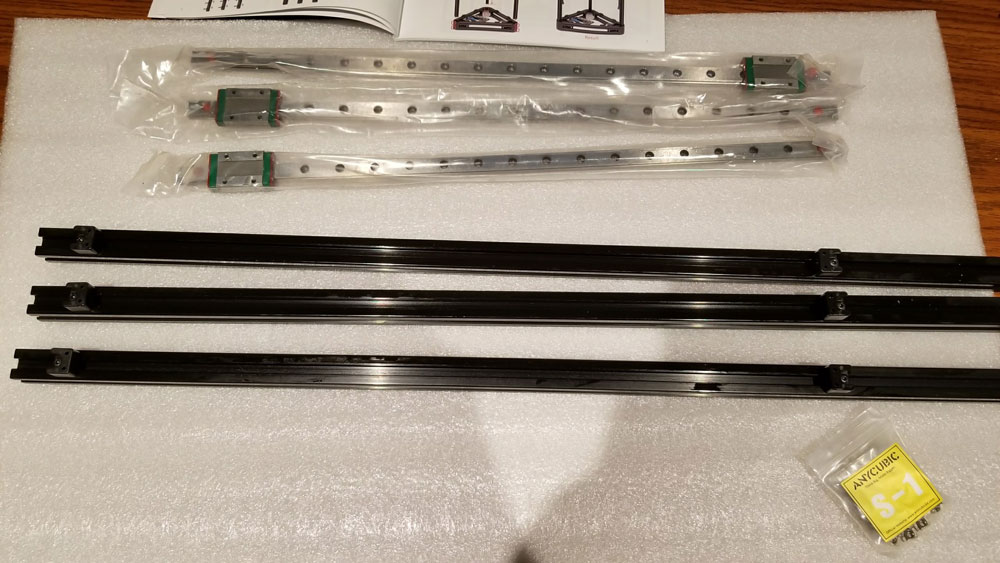

Update - If they don't want the old linear rails back, I may see if the worst one can be salvaged using some lock-tite clover lapping compound. I used the clover previously to lapp the steel shims in the mini-mill X andY axis (these are the parts that the set screws push against to adjust the tightness of the X or Y axis on the mill). Basically it is applied like grease and run though to smooth out any high or rough spots - just need to be careful to clean it all out when done. That could well destroy the linear bearings so even if it does clean up the races, the ball bearings would need to be swapped out, which is probably OK since the ball bearings that these shipped with are probably part of the trouble anyway. So my plan to salvage the worst rail (if the seller does not want the faulty linear rails back), is:

1. swap the bearings with some G25 chrome bearings I ordered, and re-pack with Super Lube, then see if that fixes it.

2. swap back in the original bearings and pack with clover and then run them to lap the races a bit, clean out all the cover and bearings, install new G25 chrome bearings and super lube and re-test.

I will post an update when I try this, assuming the seller does not want the faulty bearings back.

RSS Feed

RSS Feed