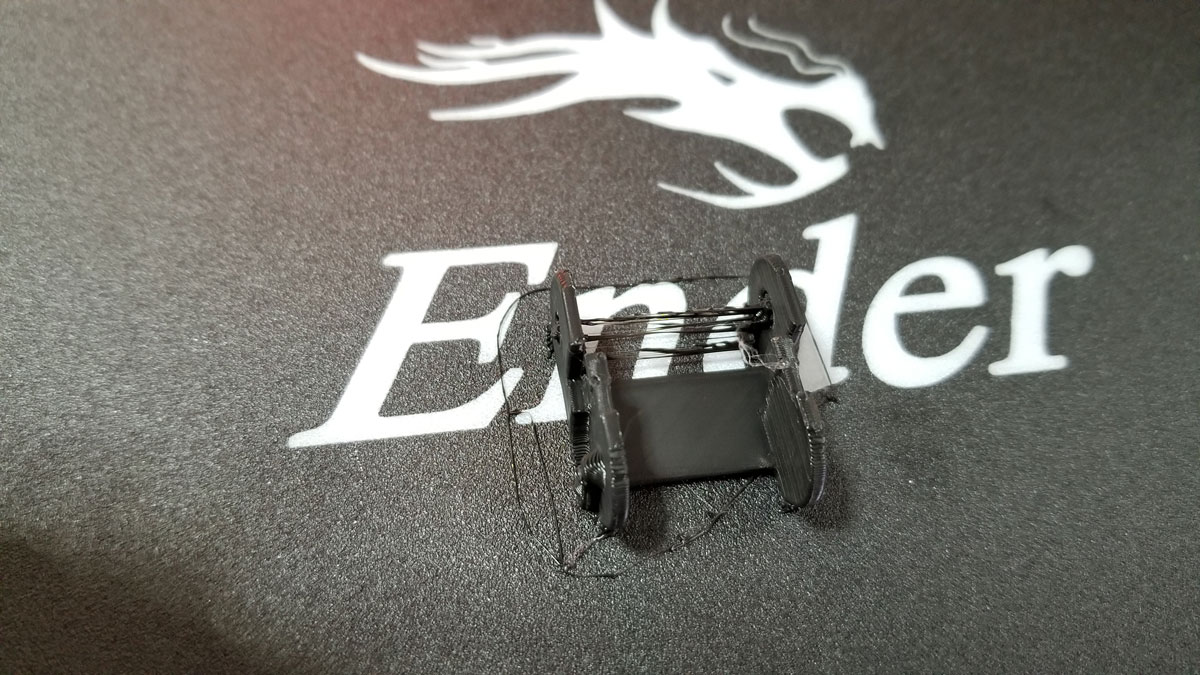

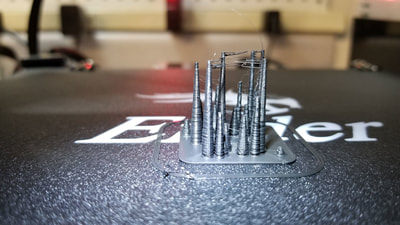

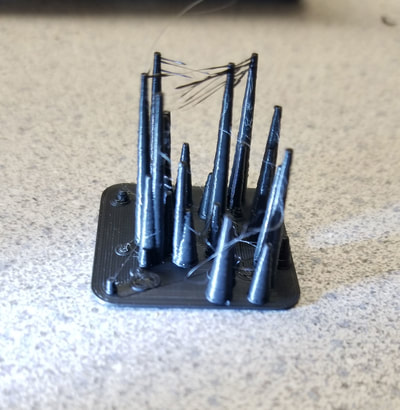

Aside from the set up issues which I don't really mind, the problems with the Ender 3 began on the first print out of the gate. I did some research first to find a good Cura profile (which seems to require a Facebook account), but then I found this video which seems to over complicate things (but oh God the music sux so be fore warned). I followed the video and set mine up to match. The first print was garbage, it looked like a drunken spider ran all over it. Then I tried calibrating the extruder (which I should have done first), and found it was only putting out 88% of what it should. I made adjustments in Cura (flow 114%) and tried again - crap, and again with different retraction settings - crap, and again with other retraction settings and lower acceleration and speeds - crap, then I swapped the Bowden tube and couplers (thanks to a suggestion), tried again - crap, then I printed a test piece, forgetting to compensate for the under-extrusion - that looked ok but it was clearly under-extruding, but when I put the flow back up to 114% to compensate it was crap again. So I am running out of weekend to mess with this thing and realizing once again, that cheap is expensive.

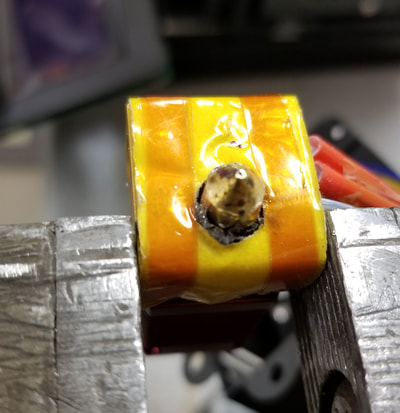

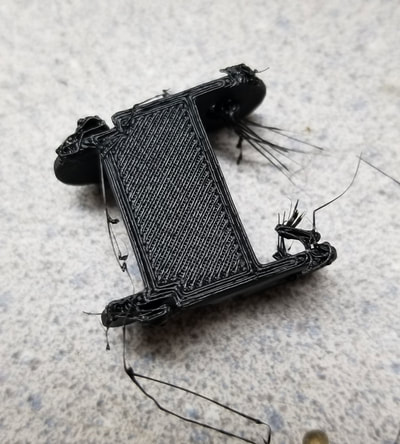

This printer is going to end up costing me about half as much again before I can hope to get a decent print from it. A lemon as it may be, I am not giving up on the Ender 3 yet, the frame is at least decently straight (no thanks to the factory), and the electronics and steppers work. What doesn't work is the extruder and hot end. The under extrusion is quite bad and even after swapping the Bowden tube and couplers there was no change. The hot end is a hot mess. I found that it had leaked PLA around the nozzle which seized it up requiring me to remove the hot end and clamp it in a vice, remove the heat blanket, clean the cooked off PLA from around the nozzle and then with a good deal of effort remove the nozzle (which at that point was ruined). I got all that cleaned up and re-assembled with new parts, but it did not help with the stringing or the under-extrusion.

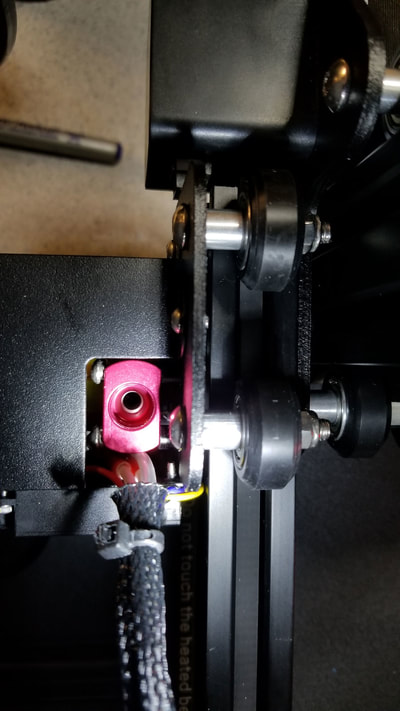

Unlike the Anycubic which uses a E3D V6 clone hot end, the Ender 3 uses a style that requires the PTFE Bowden tube to sit flush against the nozzle. I was not really familiar of this type of hot end until now (I had seen them but never used one). The weakness is that the coupler on the Bowden tube is all that keeps the clamping pressure of the tube against the nozzle, and if there is any slip, there will be a gap between the end of the tube and the nozzle - which is bad. PLA will pile up in the gap and cook off, eventually clogging up the works which would have happened to mine in short order. I have found that I don't like this style of extruder, since it is too delicate and really just an outdated design.

The E3D V6 hot end on the other hand, has a threaded insert that forms the transition between the melted plastic and the unmelted plastic (the heat break). The nozzle then seats up against this threaded insert so there is not much chance for a gap, and the clamping pressures between the insert and nozzle are much higher than the setup on the Ender 3's hot end - so it is unlikely there will be a gap for plastic to fill and burn off. Good description of this here. The E3D clone hot ends are pretty cheap, however the Ender 3 is a 24V system, which means most of the hot end kits made for 12V will not work (the fan and heater need to be 24V). So a bit more expense and work, and waiting for more parts.

Pretty clear there were corners cut in this design (had to for a $200 printer), and to that point, here are the most glaring design problems with the Ender 3 (in no particular order), as well as any fixes for them by the community of makers at thingiverse:

- Filament enters the extruder mere mm from the greasy Z-axis lead screw (fixes here, here and here)

- There is a cut in the extrusion which cables are run through from the control board, problem is it has very sharp edges (fix here)

- The fan opening for the electronics is positioned below the home position for the hot end, and is facing up, so any garbage that falls down there can go into the fan (fix here)

- Cable management is a mess, and they can get caught during operation (fixes here and here)

- The back side of the display is flapping in the breeze (cover it up here)

- The extrusions are not flat on top, though they treat the design as though they were (requires shims).

- Mine did not include any manual, only the Ikea style assembly instructions (not a big deal but would be nice to have a setup guide for the menus and board pins).

- The Z-axis end stop had an indexing tab which put it near the limit for the adjustment range of the bed (had to modify the end stop bracket to lower it) - this may be something I am missing since I have not heard of this problem before.

- No bootloader on the main board which means there are a few extra steps to get Marlin installed.

- The location and design of the extruder makes it difficult to get the filament loaded.

- Mine is under extruding by a good margin (14%), possible fix with an extruder mod here.

Some of the good points are:

- It is relatively inexpensive at $200.

- 24V should help with heating things up faster.

- There is a large community for the CR10 and the Ender 3 is really just a small CR10.

- the carriages are metal and there did not seem to be any alignment issues with the wheels.

- All the holes for the parts were spot on.

- It was 60-70% assembled - though the base did need adjustment to sit flat.

- The build tac suface works well and is not glued on, but rather stuck to some hard plexi material so it can be easily removed or replaced.

- Cables and wires are well labeled, even at the motherboard end.

- They seem to have fixed several issues with earlier models of the Ender 3 so Creality is improving things.

I am probably biased against this printer after all the time I have wasted to get it working but I think the above is still pretty fair and I still have hope that I with some more work this printer can make some good prints.

My plan now is, instead of trying to fix something that is likely to never work right, I am going to try and swap the hot end with an E3D V6 clone and the extruder with a titan clone which I am going to mount as a direct drive. I am also going to install TL-Smoothers and install Marlin. I'm not going to spend much more time trying to fix on the Ender 3 until I get these upgrades installed, but may try some simple prints on it. Maybe if I am lucky I will get a good print out of this after that is all done. I do have a job though, and this printer has stolen most of my weekend so I am going to step away from it for a while (need to wait a couple weeks for parts anyway).

RSS Feed

RSS Feed