|

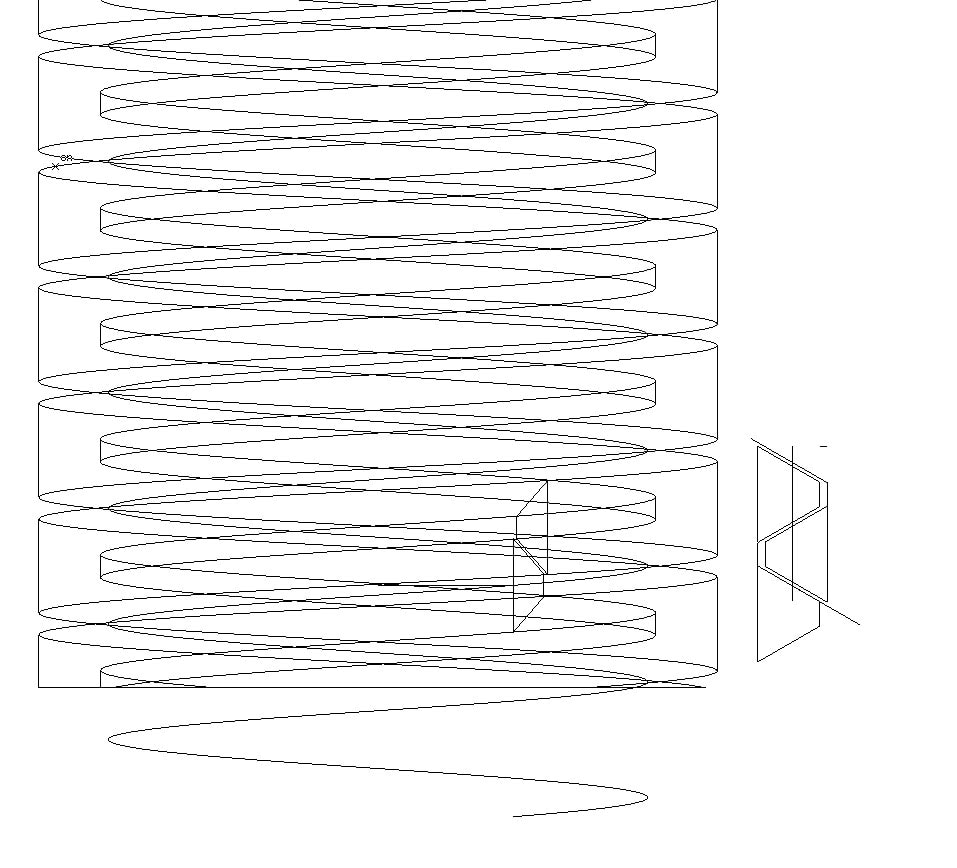

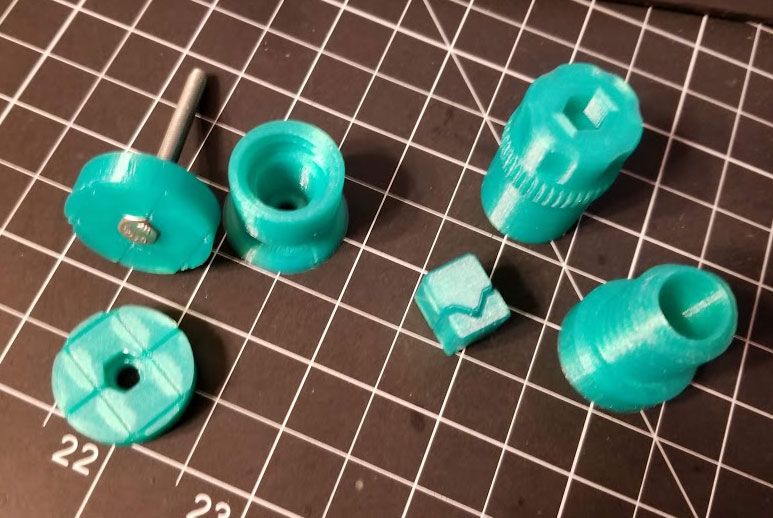

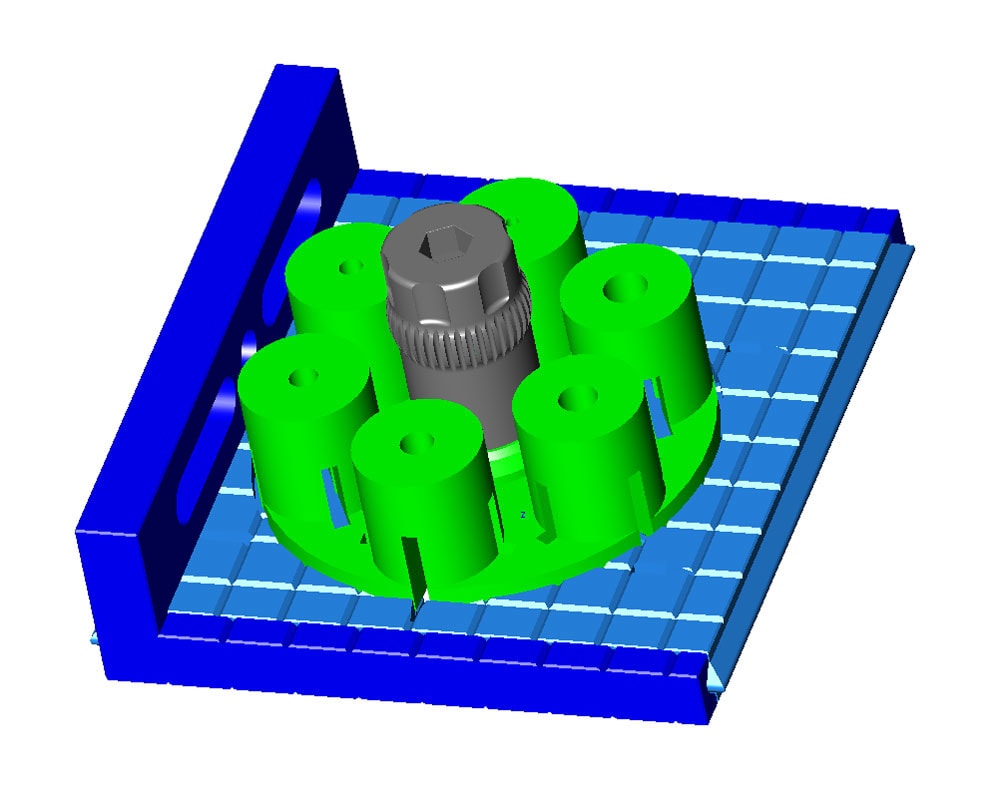

Not really a how-to, but I found that using ViaCAD 9, I could make a reasonable printable thread by first making a closed surface of the thread profile, then mating that up with a helix spline that was set up with the correct pitch and diameter I needed for the threads (in this case 3mm pitch and I think it was 14mm diameter). After that I used the one rail sweep solid tool to spin the thread profiles up the helix, and bam! I had threads. The only problem I had after that was finding the balance to make them usable on a printed part. My first test was was too tight to turn by hand. I ended up with a gap between the threads around 0.4-0.5mm (closer to 0.5mm) and that was able to work with a layer height of 0.15mm when printed. The thread profile in the pic does not reflect the final design since I had to tweak the threads with the push/pull tool to get the correct gap. Since I knew I was gonna have problems with the threads I printed some smaller test parts first to dial in the threads. Now just gotta print the part.

0 Comments

Leave a Reply. |

Stoopid MeWelcome to my Stoopid corner of teh Internet. It's mostly gonna be 3D printing stuff, but I also post some recipes, projects, and the occasional rant here as well. More Stoopid stuff is updated regularly. Archives

July 2024

Categories |

RSS Feed

RSS Feed