These I think could be a help generally:

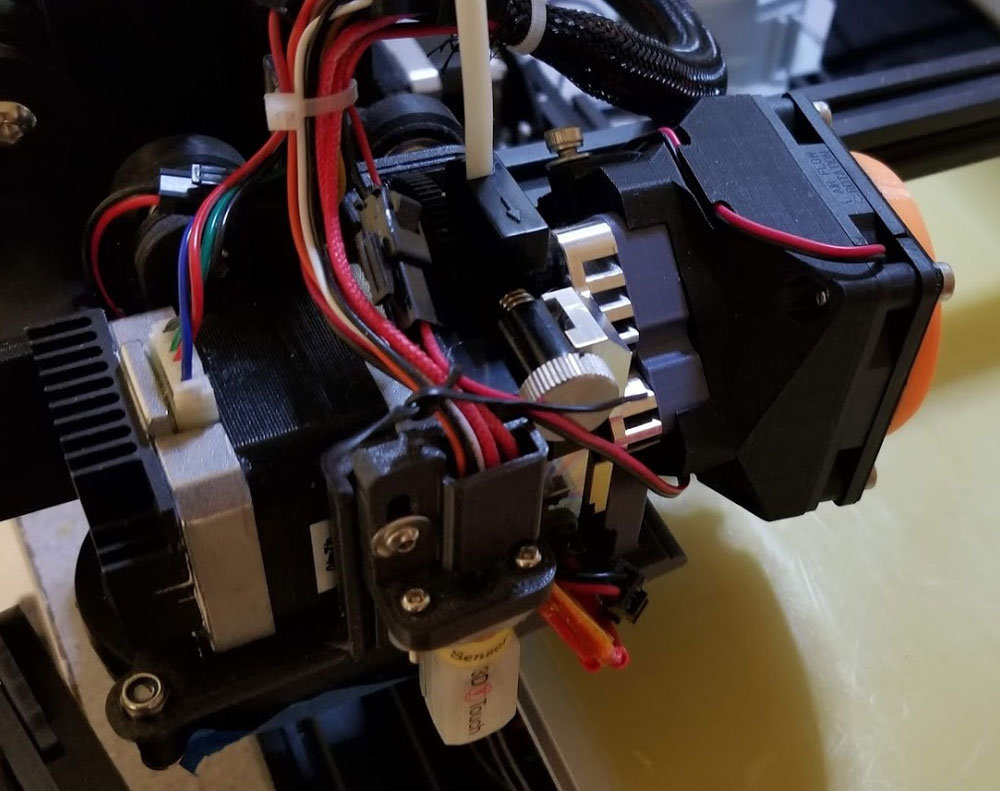

- Swapped the bearings with the ceramic bearings linked here (https://www.amazon.com/gp/product/B00GGQGM36)

- Printed and installed the top filament guide linked here (https://www.thingiverse.com/thing:2600963)

- Chamfered the inside edge of the PTFE tube going into the heatsink. This is the edge that the filament will first touch as it goes into the guide. The edge of the PTFE that buts against the heatsink is cut flush.

I think that the top filament guide (#2 above), also has kept the filament from getting ground and cut when there has been a jam with this setup (jam was due to filament twisted on the spool).

These additional mods helped in my case due to the stepper getting too hot and the printer being located in a hot environment:

- Added a more powerful (60mm) fan to cool the Titan Aero heatsink.

- Add a heatsink to cool the stepper, and reduced the stepper current.

Overall I am happy with the way the Titan Aero is now performing and have only one upgrade left on it, which is to install a pancake stepper.

RSS Feed

RSS Feed