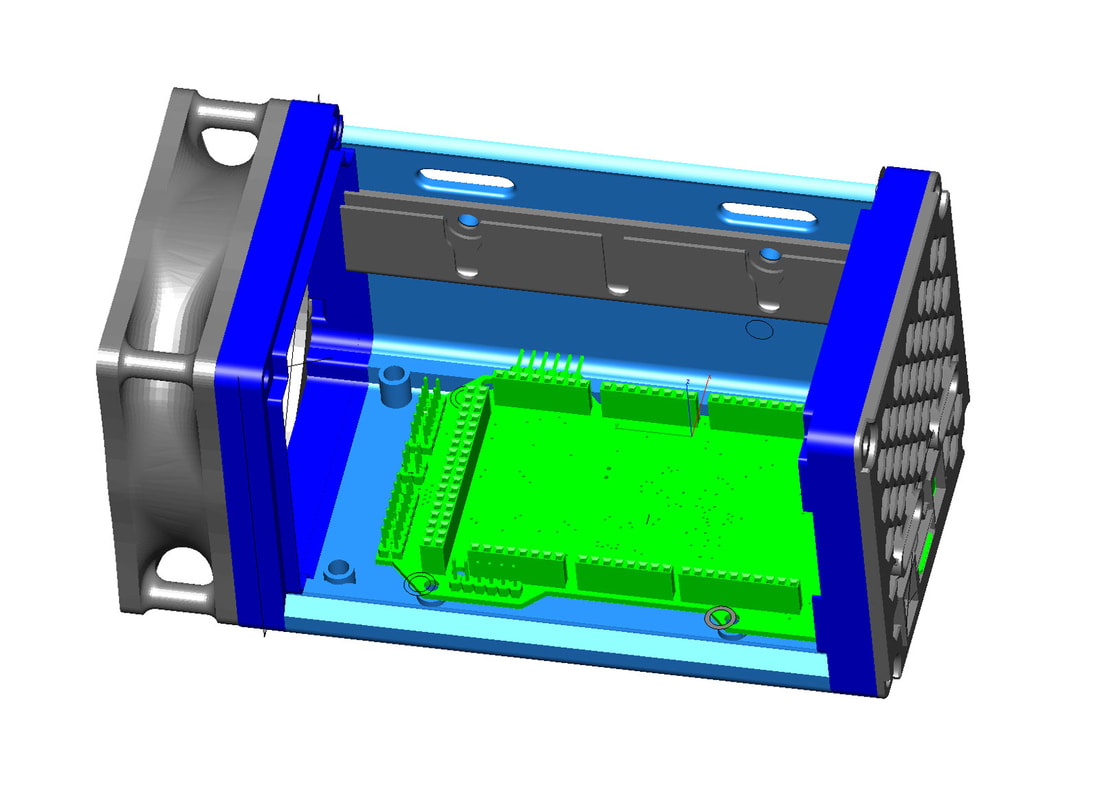

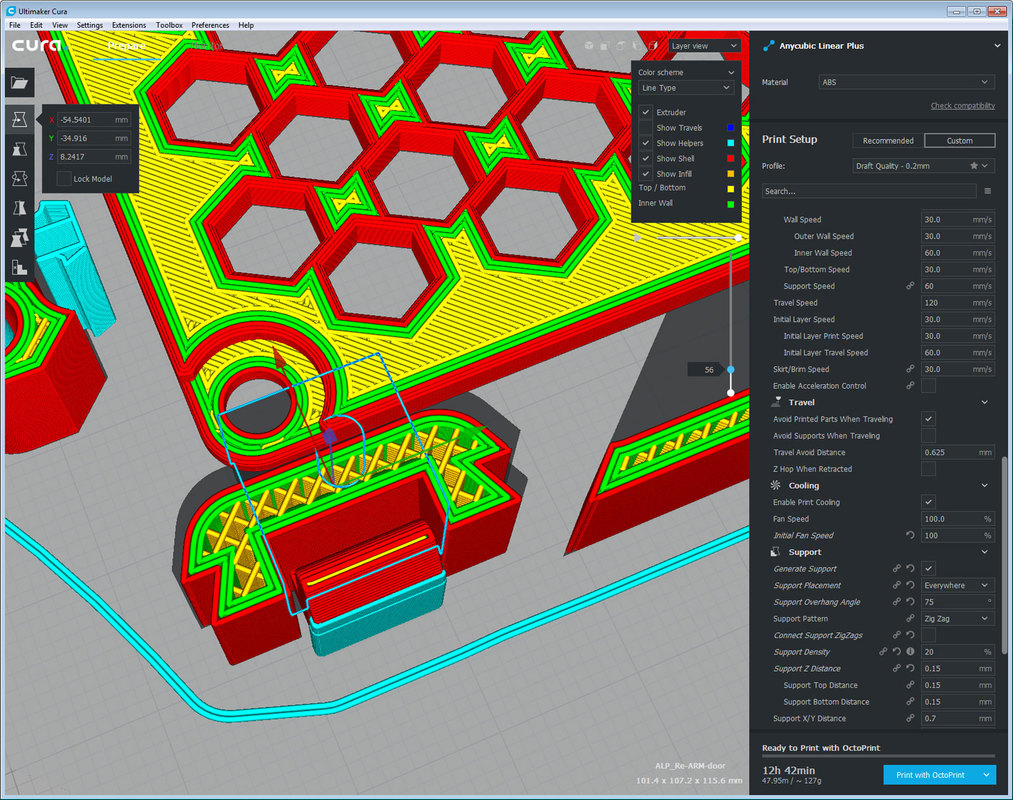

The design uses an 80mm fan which can either push or pull air though the case. The top and side swing up on a hinge and there is a latch on one side to secure it. The latch uses a spring from a cheap ball point pen which has just the right amount of force. Since the case is low profile, I had to use M3 and M4 inserts on it, which are not something most people have around, but that was the compromise since if I had used nuts instead it would have been larger than I wanted it to be. I have only printed parts of the case to test various things and am printing the design now. I've made a face plate for both the RAMPS 1.4 (shown) and a more generic plate which I plan to use on my RAMPS 1.6.

|

Since my printer (the Kossel not the POS Ender 3) is working again, I started working on the case again for it. I didn't like the old design and wanted something that would be easy to work on, modular and simple. Tooless would be ideal, and I wanted good airflow since I planned to use TMC drivers which run hot. This is the result (currently).

The design uses an 80mm fan which can either push or pull air though the case. The top and side swing up on a hinge and there is a latch on one side to secure it. The latch uses a spring from a cheap ball point pen which has just the right amount of force. Since the case is low profile, I had to use M3 and M4 inserts on it, which are not something most people have around, but that was the compromise since if I had used nuts instead it would have been larger than I wanted it to be. I have only printed parts of the case to test various things and am printing the design now. I've made a face plate for both the RAMPS 1.4 (shown) and a more generic plate which I plan to use on my RAMPS 1.6.

0 Comments

Leave a Reply. |

Stoopid MeWelcome to my Stoopid corner of teh Internet. It's mostly gonna be 3D printing stuff, but I also post some recipes, projects, and the occasional rant here as well. More Stoopid stuff is updated regularly. Archives

July 2024

Categories |

RSS Feed

RSS Feed