I decided to keep the plate and instead of holding it with clips, I used screws by drilling four holes through the plate and countersinking them. I still think that method will work, but unfortunately when I set my bed up the holes were probably too tight and so heating the bed likely warped it as it bucked up in the middle, that is my suspicion at least. I didn't immediately make the connection since at the time I also had an inductive probe and thought there was some trouble with the combination of inductive probe and magnetic bed, however the mesh with the inductive probe was similar to the mesh with the 3D Touch probe I later installed (though the 3D Touch probe seems quicker to probe the bed).

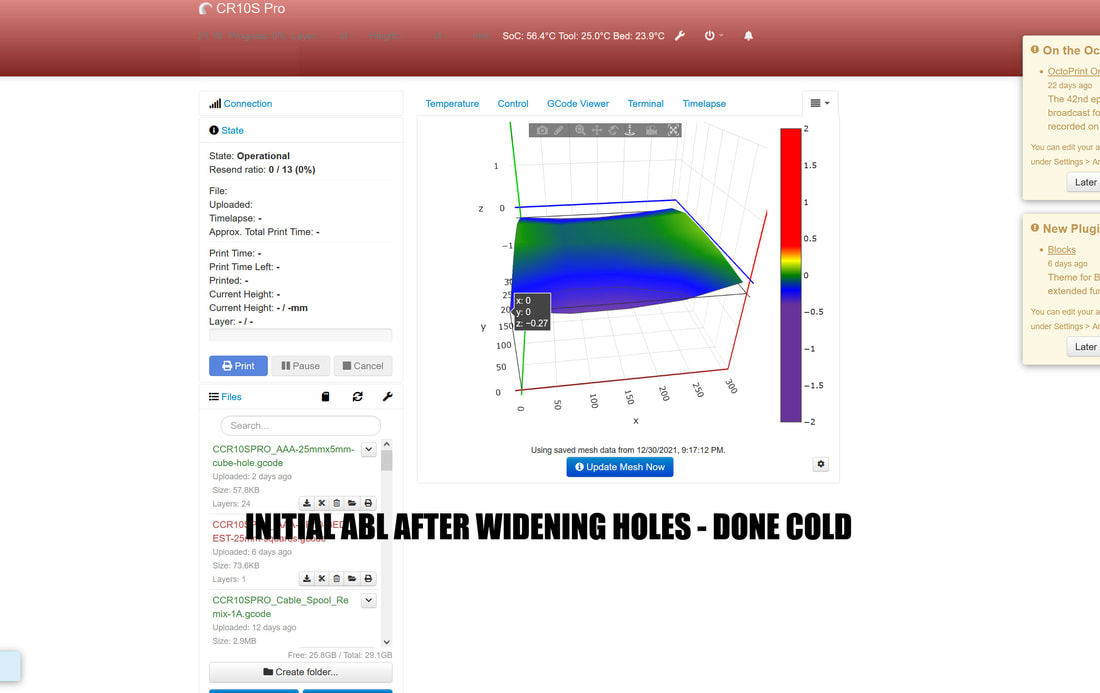

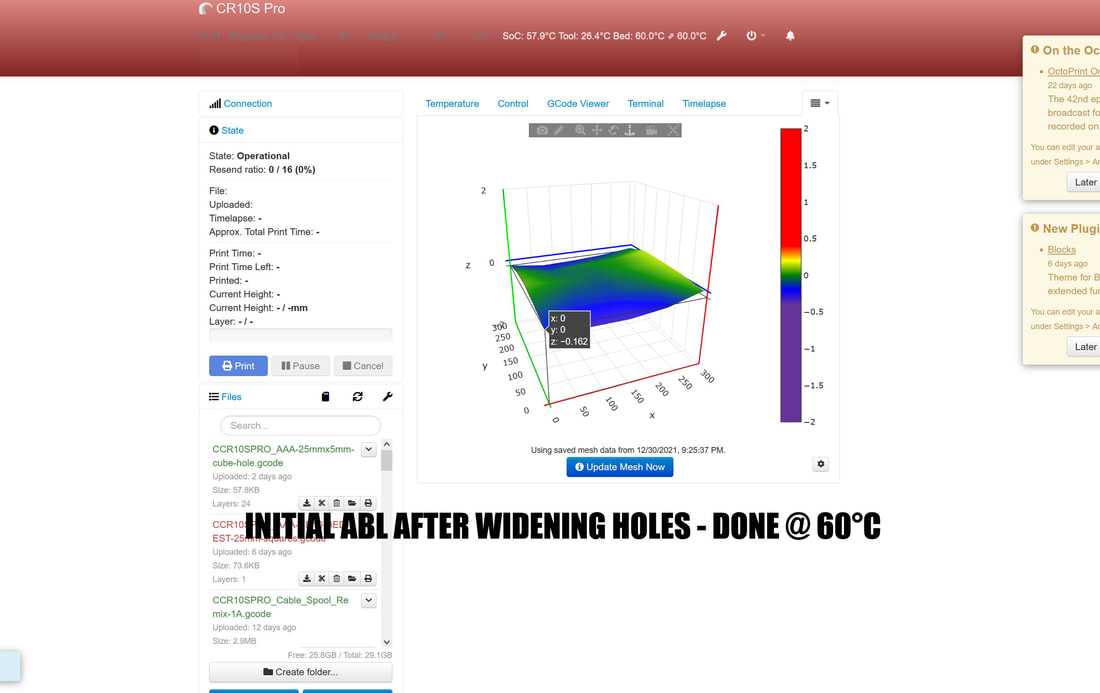

My fix to stop the problem from getting worse was first to open the mounting holes I made in the plate, and second to only tighten the screws holding the bed snug, and not to torque them too much. The bed still feels solid and I don't expect anything to shift. I think these changes will allow the plate to expand and contract without warping further. That is just a theory though, and I may have warped the plate some other way, though I did not notice anything when working on it and it was always fully supported when drilling the holes (I used a backer of press board).

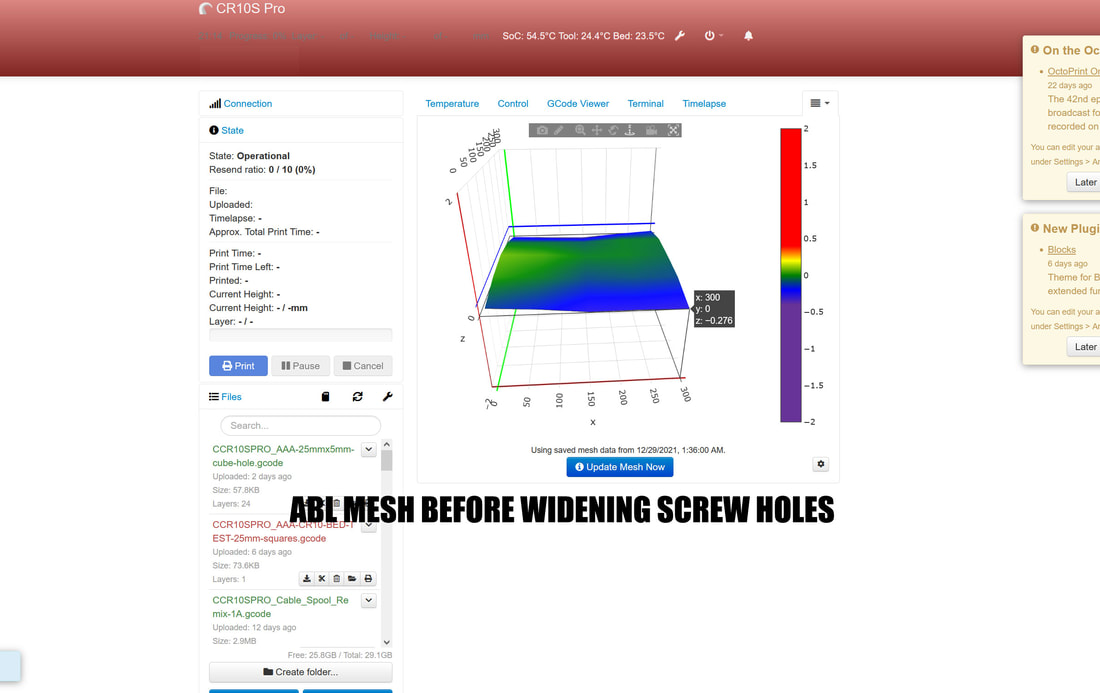

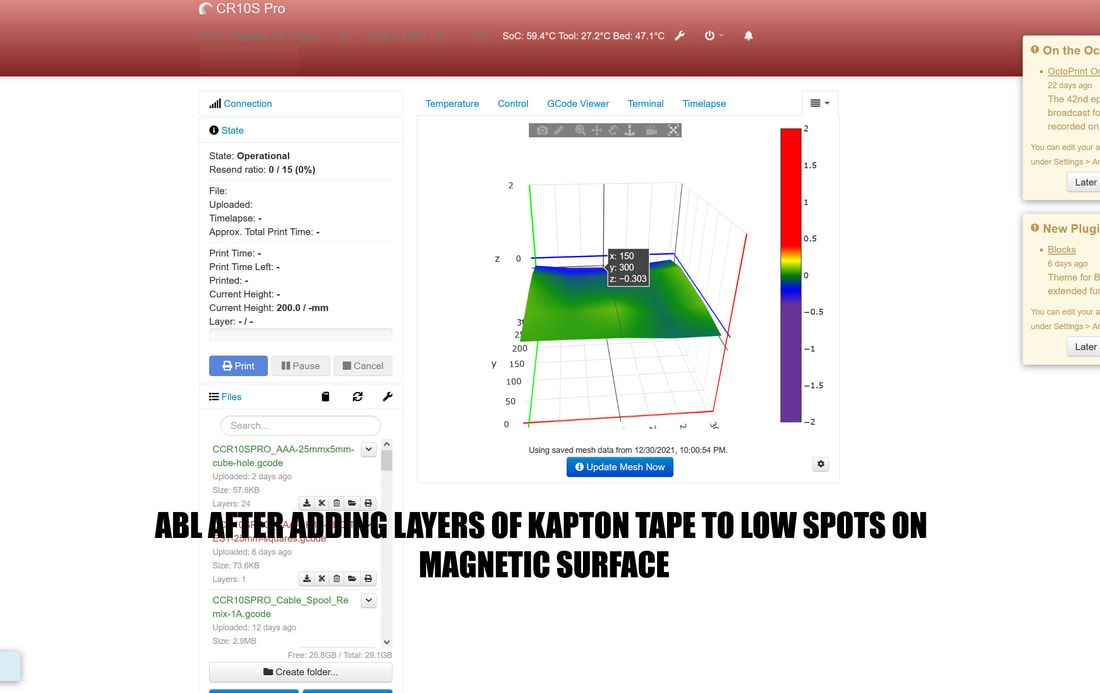

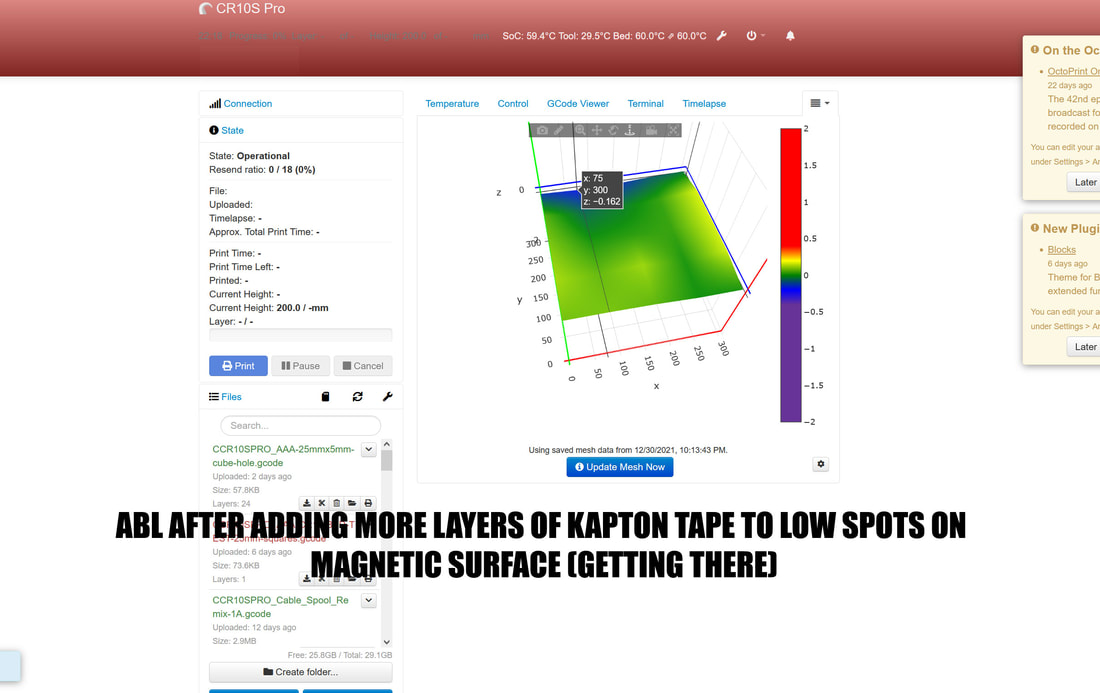

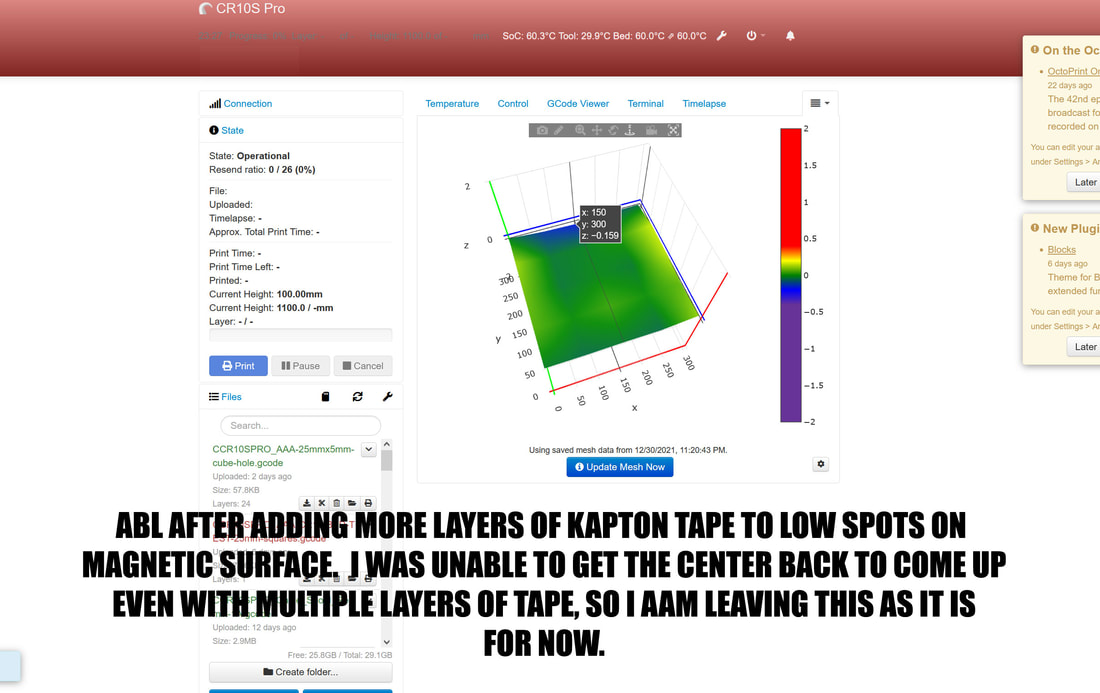

In any case my bed is now warped and I'm not feeling like spending 60 bucks to swap it. I decided to try adding some Kapton style tape to the low spots, after getting the wheels set as best as they could be. This is what I had to start with, there is a high bulge right across the center which is parallel to the x-axis:

RSS Feed

RSS Feed