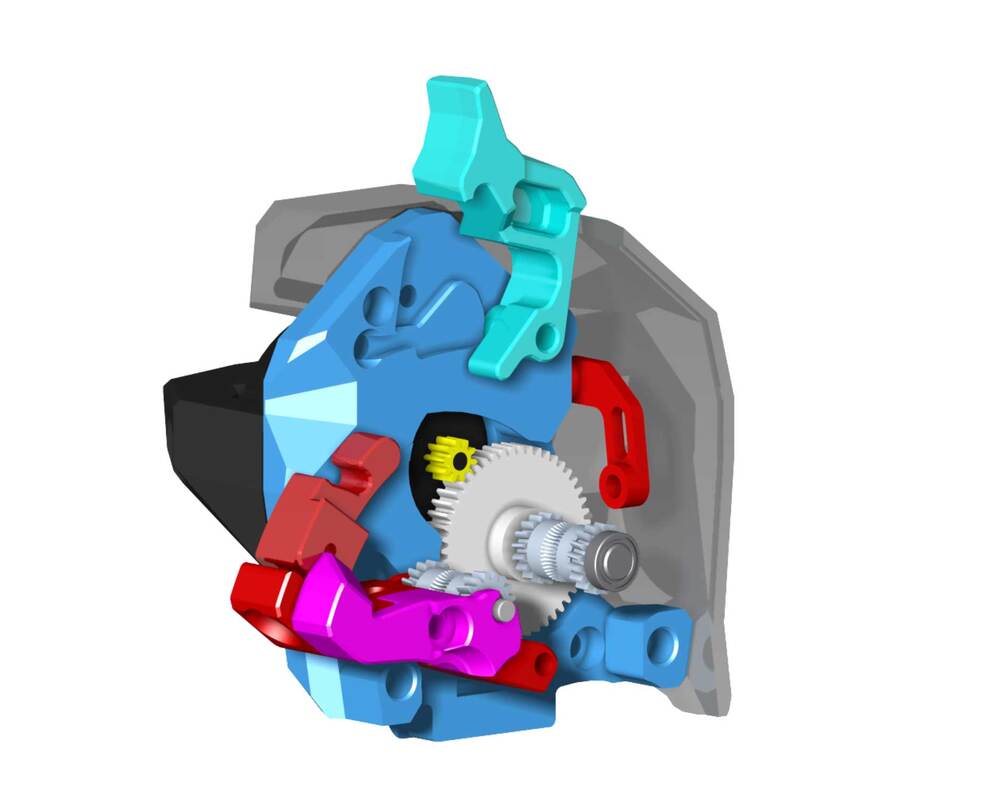

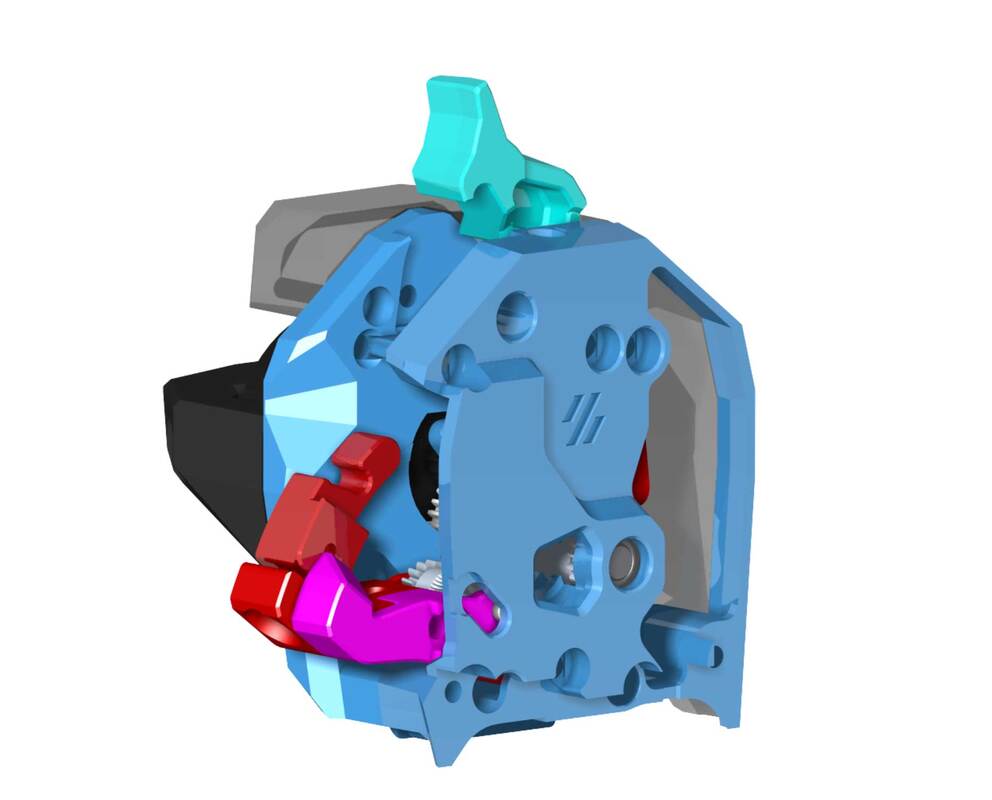

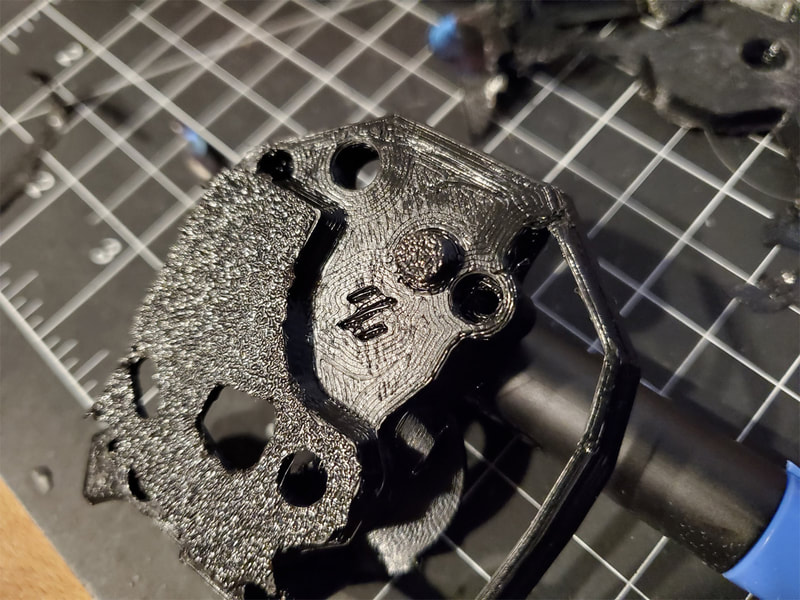

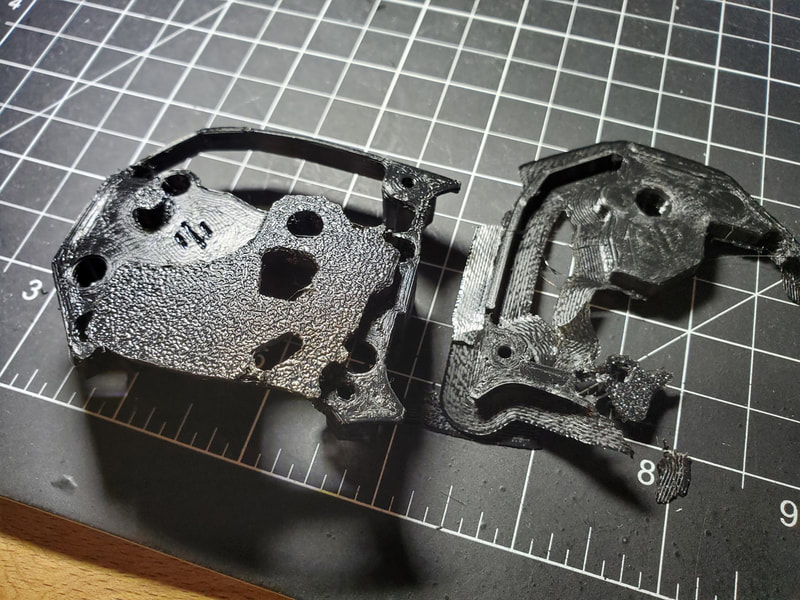

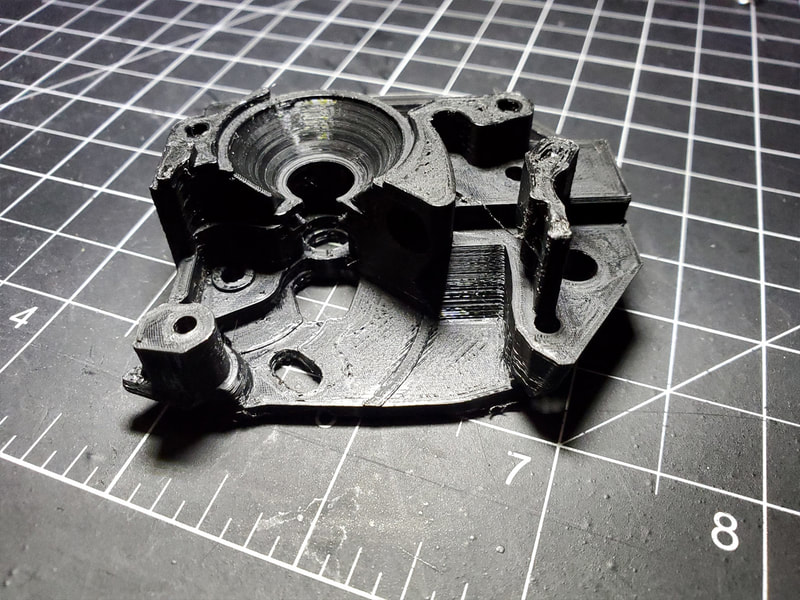

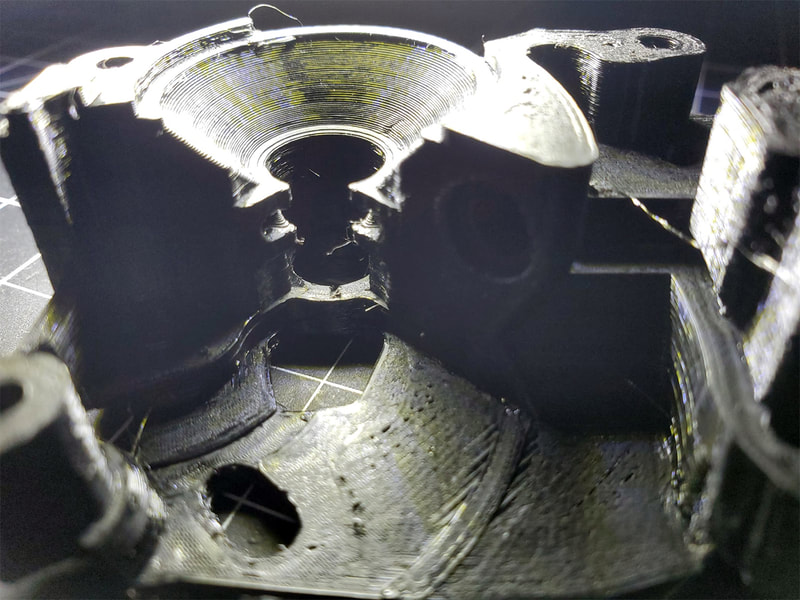

The basis for the model I am modifying here is the Steathburner clockwork 2 (thanks to VoronDesign for posting the STP files!)

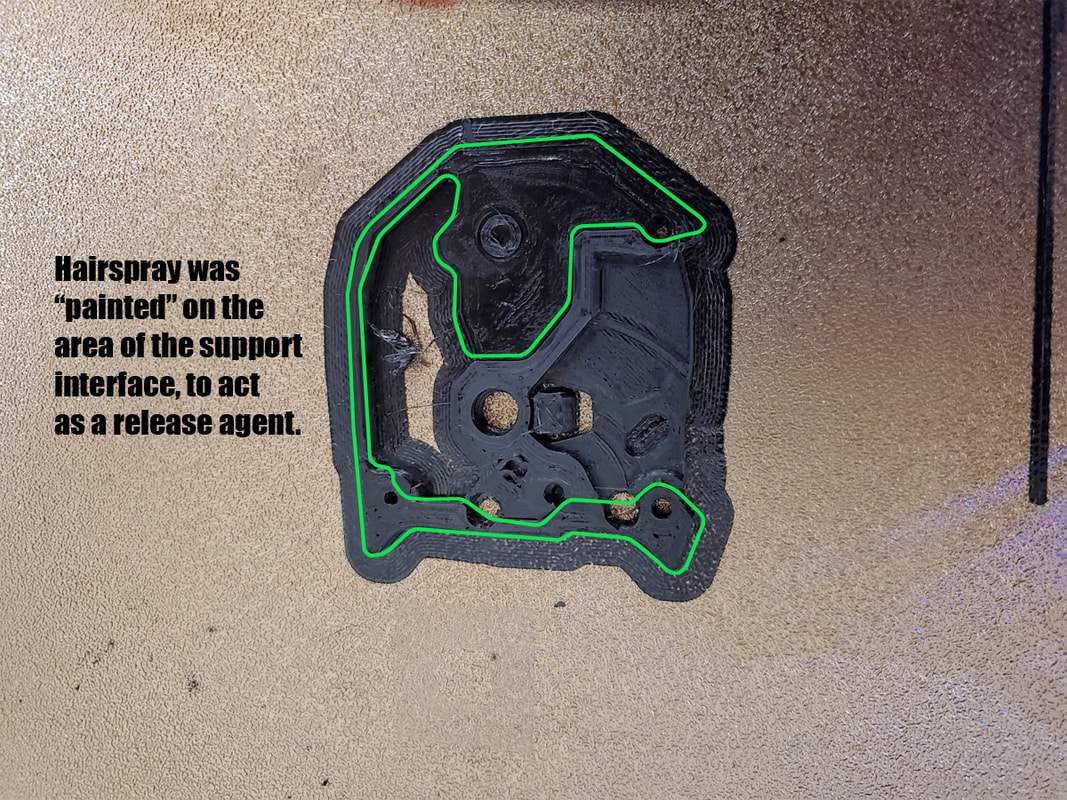

I'm waiting for this print to finish up, but added some pics to show how the hairspray was applied.

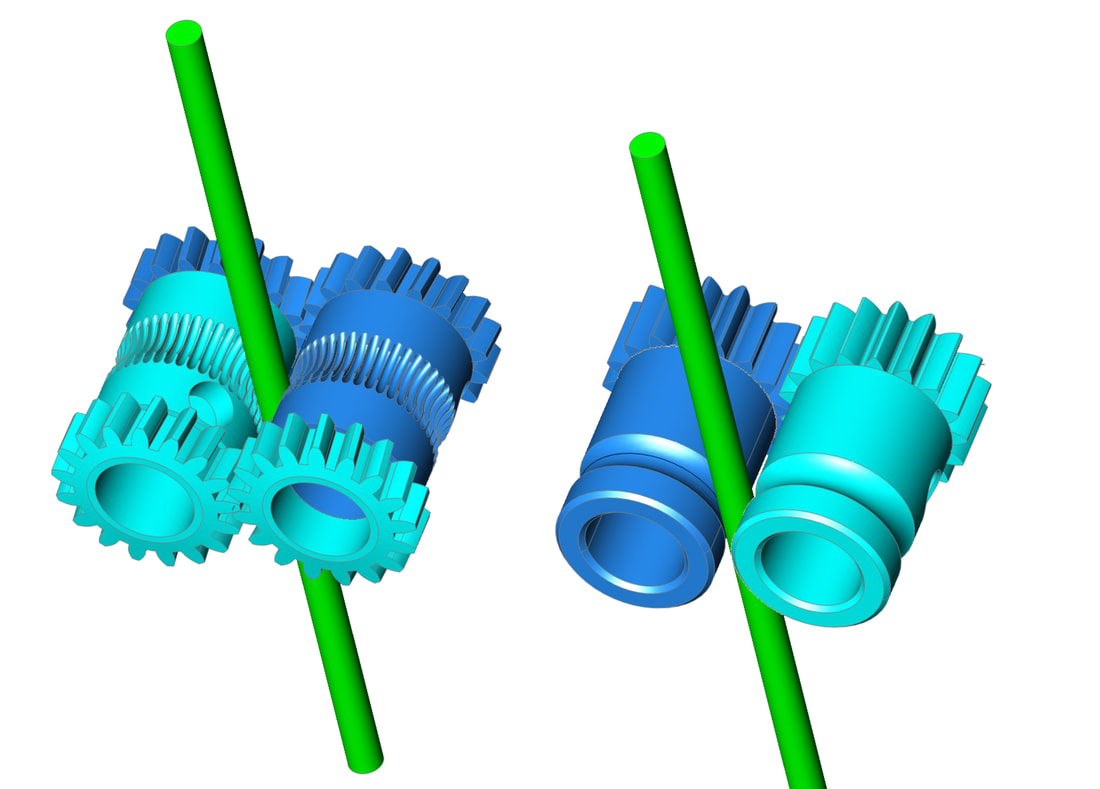

Update 5/1/2023: I lost one of the helical gears, so I'm not going to entertain this idea anymore. However there are now helical gears for the BMG clones, which look like an easy direct swap, without all the re-working of the clockwork to accommodate a different filament path through the extruder.

RSS Feed

RSS Feed