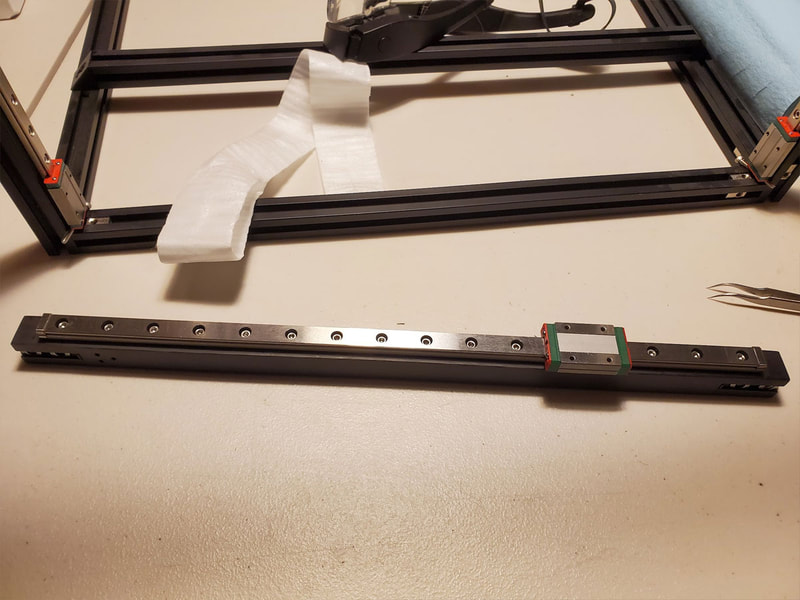

To hopefully remedy this issue, I am designing a tool to assist with installing the backing nuts and washers for the rail, and some end plugs (which will be permanent), to assist in mounting the ends to the Voron printed parts for the x-gantry. I'm still printing these parts, but have done some test parts, and they should fit (once I tuned horizonal expansion for the filament). Once verified, I will upload them to Printables to anyone else who bought this CF rail from FYSETC, and finds themselves in the unfortunate predicament of having to install it.

I'm considering doubling down on the stupidity and may pick up a CF XY Joint, however I'm not completely sold on the idea yet. I do think lowering the mass of the moving gantry is a win-win though, since F=M*A, it will allow faster acceleration or lower forces (and possibly better quality). Using a CF XY joint will also allow me to glue the XY joint to the CF rail which could help with rigidity, but also limit my options if I need to make changes. But it would also mean waiting another three weeks for parts, on a build which is already taking way too long (sorry, there have been many things going on and other more pressing projects have taken me away from my Voron build).

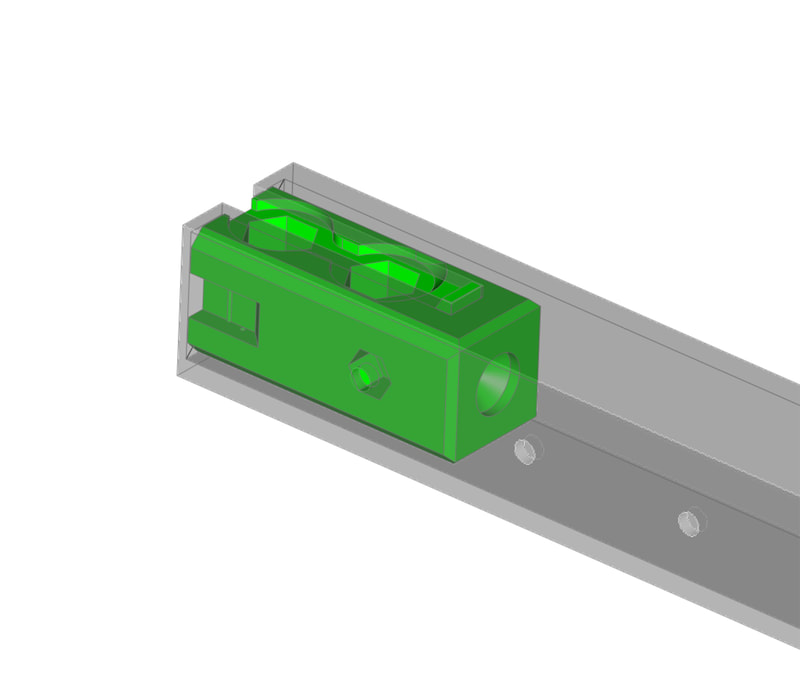

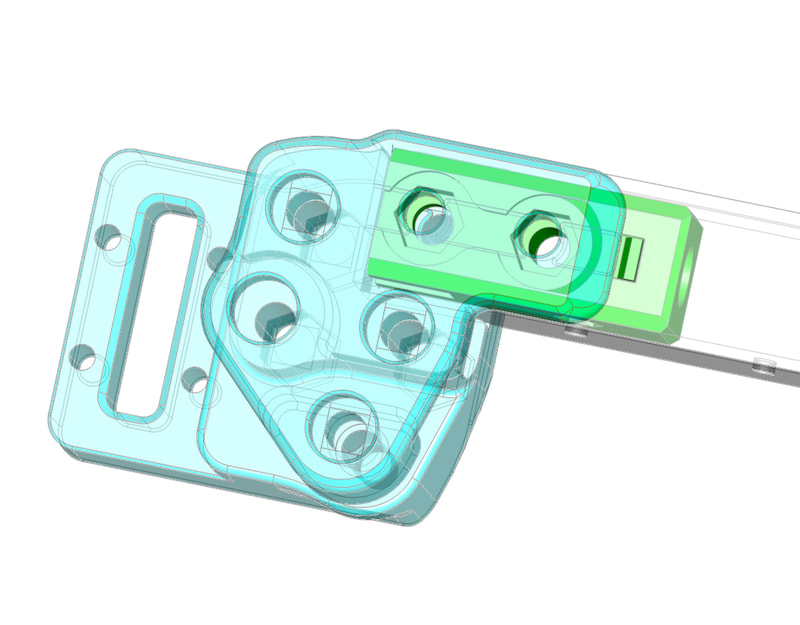

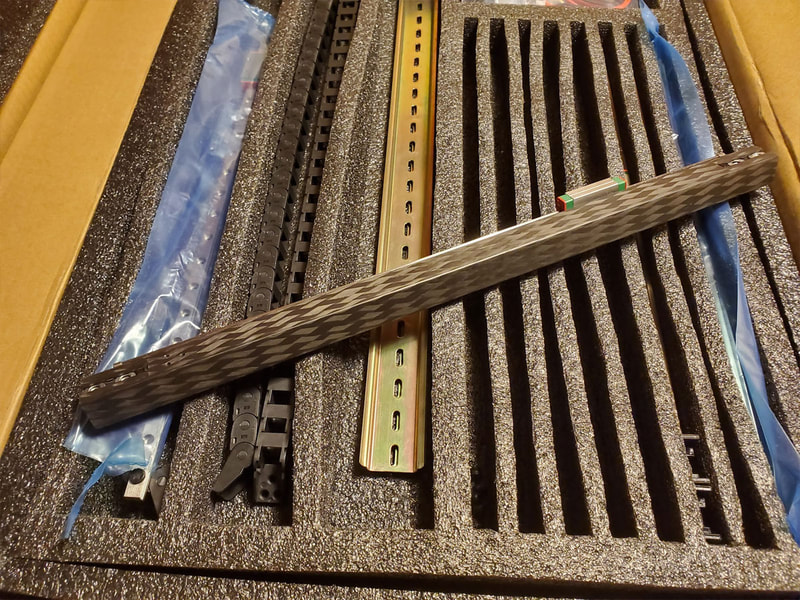

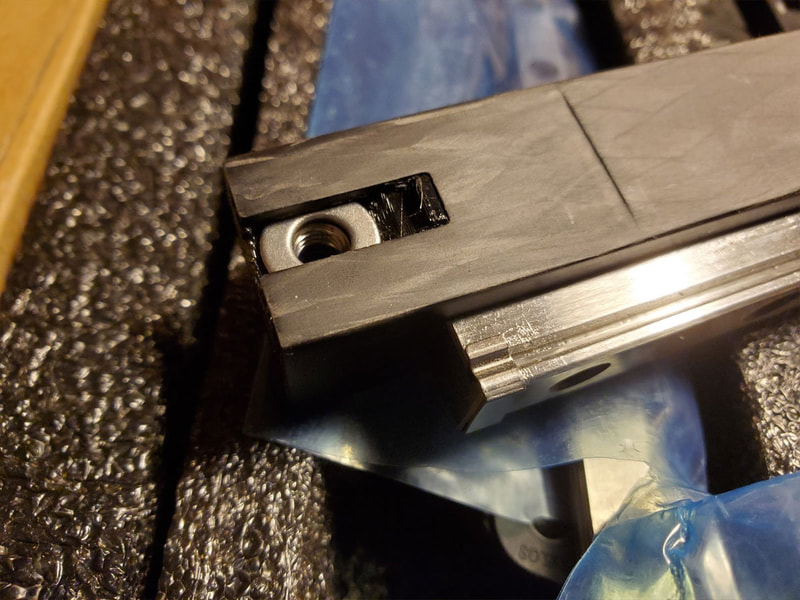

The pics below show how the plugs will work, they are the green parts. The plugs have pockets for M5 and M3 nuts and washers, and these plugs will slot into the ends of the carbon tube. There are some indexing bumps on the plugs which fit in the slots milled in the CF tube as well. The part has a lot of internal reinforcement holes which will help keep the walls from collapsing when the nuts are torqued down. They do require some tuning of the filament flow, and horizonal expansion however, since they are a snug fit (or some sanding will also work).

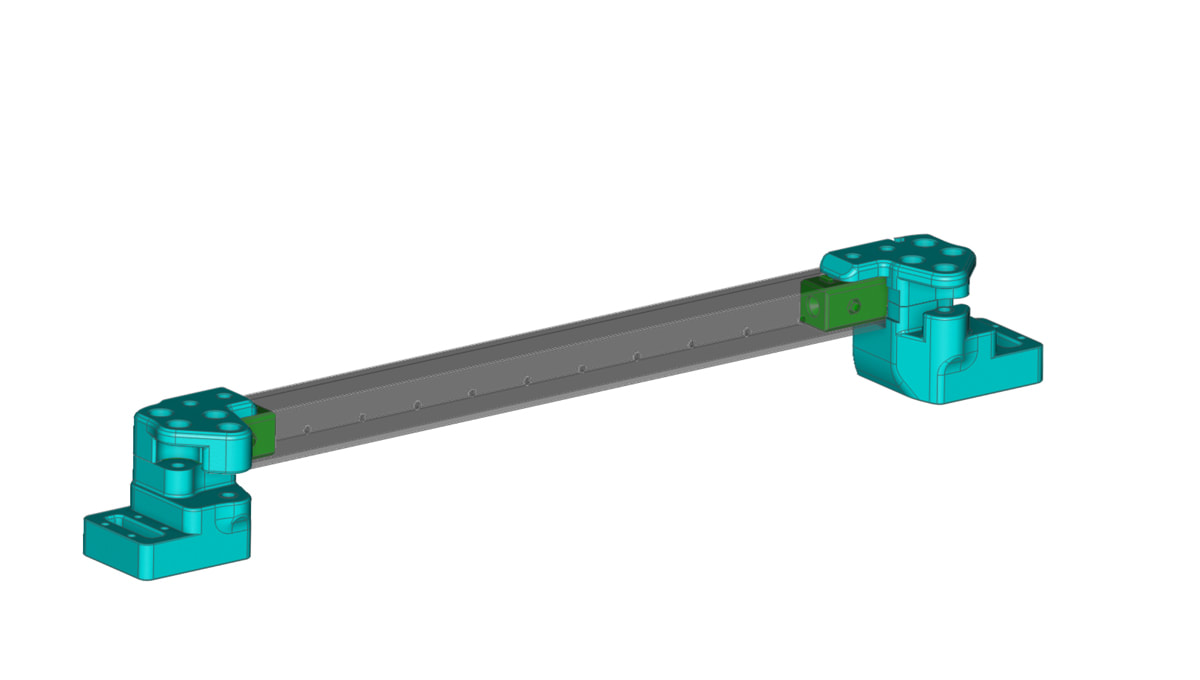

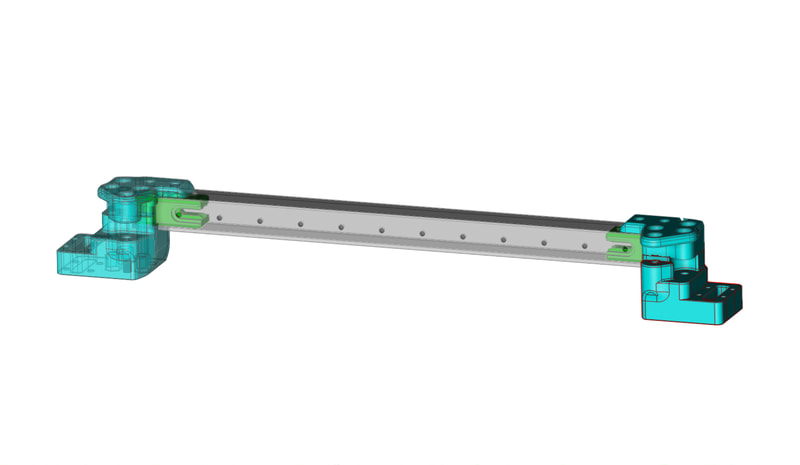

Update 3/25/2023: I made some changes after using the tool to install the rail. It works, but it needed to be longer. The end plugs are also modified so they will not capture the nut for the ends of the rail, and instead those will just slide into a slot (see the 7th pic below). After looking at the design I realized that it is set up to allow the XY carriages to be slightly adjustable in and out on the X axis, so I did not want to have them locked into place without any means for adjustment. It also allows me to use one part for the left and right sides. These revised models are printing and once tested, everything will get uploaded.

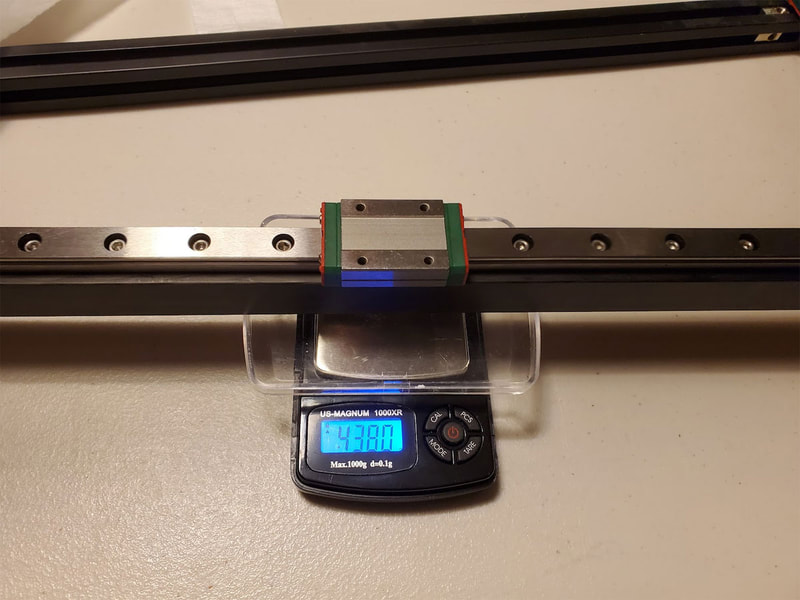

Update 3/26/2023: I installed the plugs, though I have not installed the XY Carriages on them yet, however the spacing is set up according to the Voron Model, so I am pretty sure they will work. The X-Axis rail, with the plugs and the MGN12 linear rail installed, comes out to 438 grams (this does not include the XY joints). I unfortunately forgot to check the weight of the rail without anything connected to it, which sucks, since the AliExpress listing also fails to mention the weight, but I'm sure it's less than the aluminum extrusion and more importantly, it will not be subject to the effects of thermal expansion (though the steel rail will be).

The models are now posted at Printables, use 'em at your own risk since if the linear rail nuts spin out, I have no idea how to get them tight. I did not have that problem, but I mention it since it was what I worried about, and made sure to test the tools before using them. I tested the tools by tightening several of the locknuts down with screws while in the tool, to make sure it could hold them secure, and not spin out.

https://www.printables.com/model/433867-voron-24-r2-cf-tube-end-plugs-and-rail-install-too

Also interesting related to the design I posted is that there was already this design out there, which appears to have been part of the concept for these rails. So I pretty much re-invented the wheel here :D It's interesting how both the linked design and mine, share the same method to install the MGN9 rail nuts (though I think I like the additional handle on the tool I designed). I believe my design still has some merit, though the end plugs on the linked design appear to be a lighter weight design which is preferable. The end plugs in my design have internal reinforcements, though if the plugs are made of a tough material (and have enough walls + infill), the difference is probably negligible there.

RSS Feed

RSS Feed