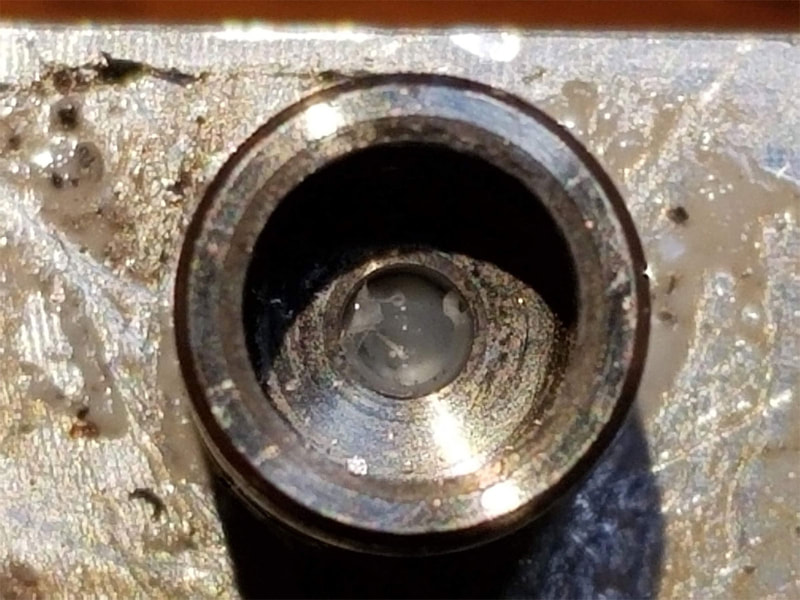

Updated 10/2/2020: I received the replacement heattube but I still cannot get it to fit in the heatsink, so it must be something with the heatsink. It's a very odd problem since the heatsink looks fine, and both heat tubes measure the same OD. Will need to see what they say, but the CR10S Pro will be down for a while. Fortunately the Ender3 is working OK.

Updated 10/13/2020: They sent me the replacement heatsink which fits the replacement heatbreak like a glove, but oddly the old heatbreak did not fit the new heatsink. But my CR10S Pro is back in business, and it is thanks to the great customer service from MicroSwiss, which was fast and helpful, despite the USPS taking their time getting it here.

I really like the design of the MicroSwiss all metal hot end, it is much easier to work with than the V6 or stock hot ends, and the titanium heatbreak seems to work really well with PETG as well as PLA. I did put my stock hot end back on for a couple days during the downtime, but then decided that I did not want to burn the PTFE tube running over 240C on PETG so stopped using it till the replacement parts arrived. The time was not wasted though, I swapped the build surface with a gizmodorks PEI sheet which works great, and checked a few other things on the printer. I'm now thinking of adding a direct drive mod (thinking of using the Hydra design by boothyboothy at thingiverse since it is easy to swap the extruder).

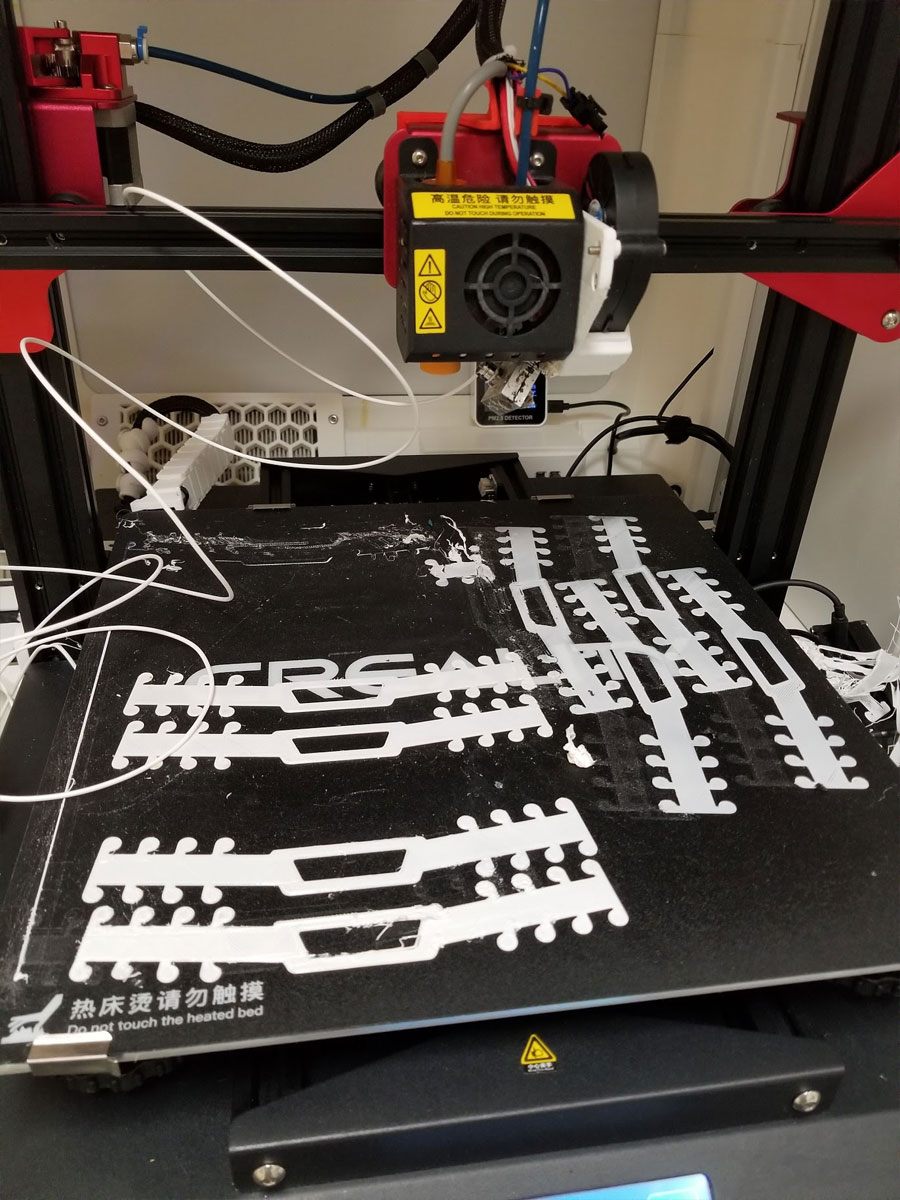

Edit (10/27/2020) The Hydra duct will need to be remixed for my cr10s pro, which I can do, but I first need to locate the STP/IGS/STL file for the stock x-gantry/hot end mount for the CR10S Pro which is different from the CR10/Ender3 design.

RSS Feed

RSS Feed