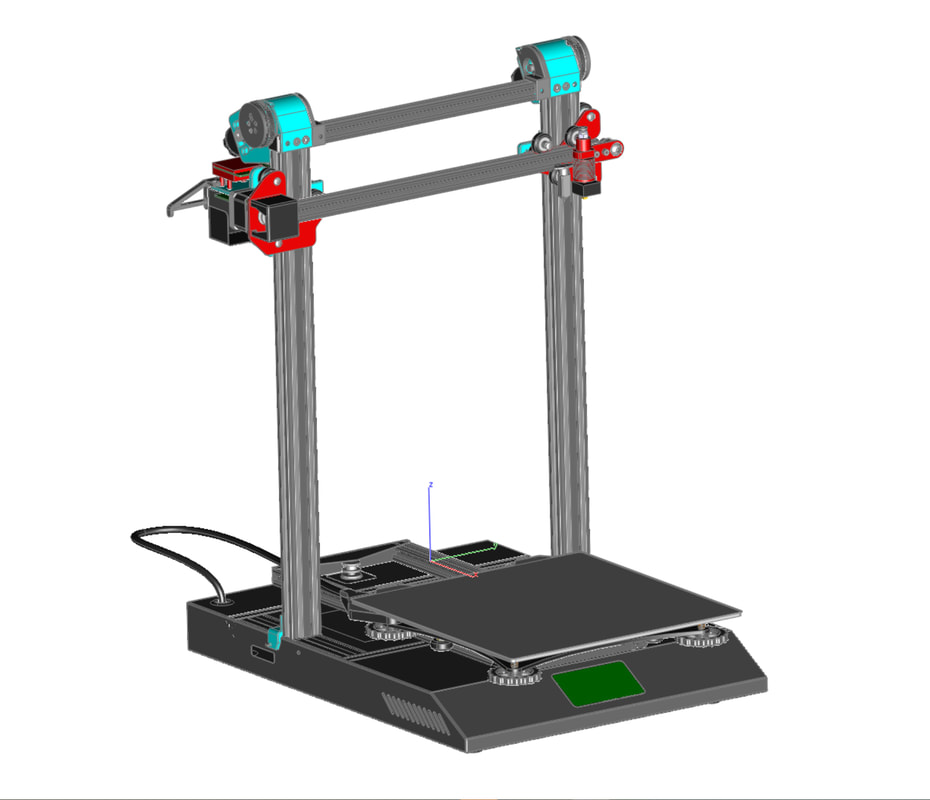

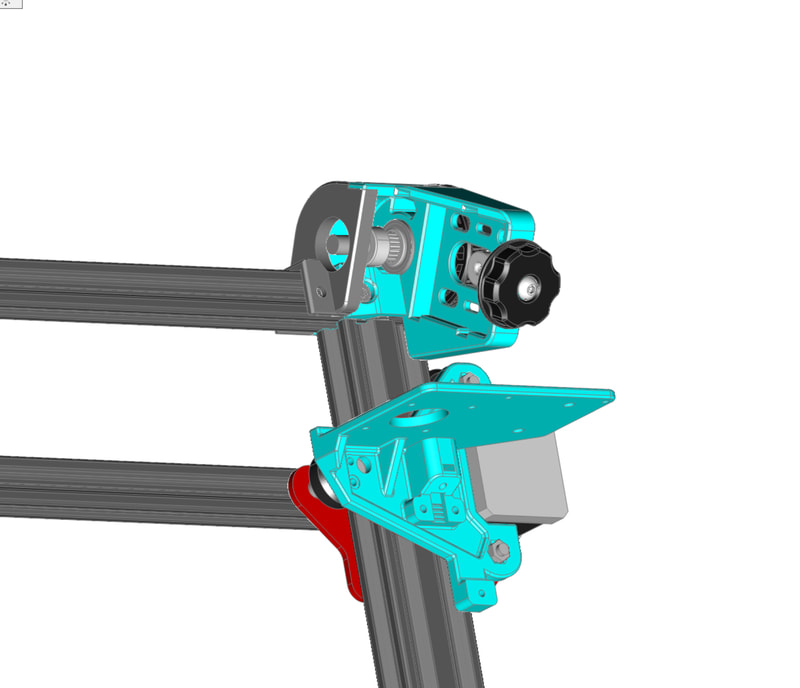

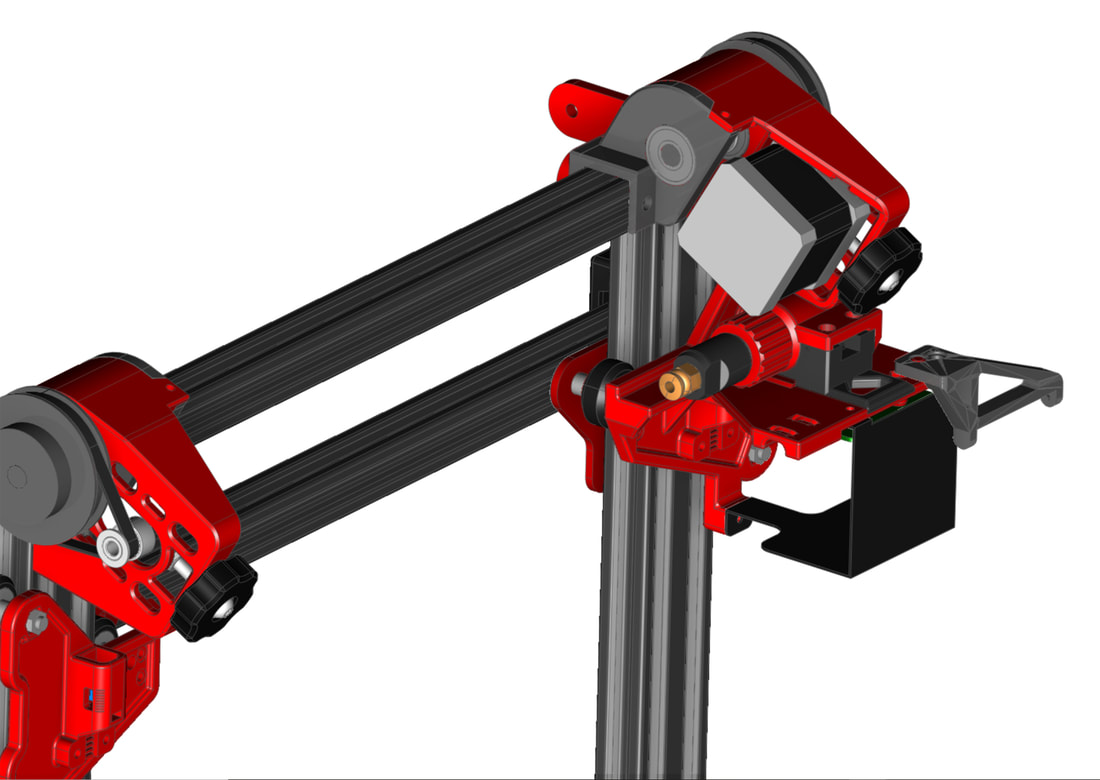

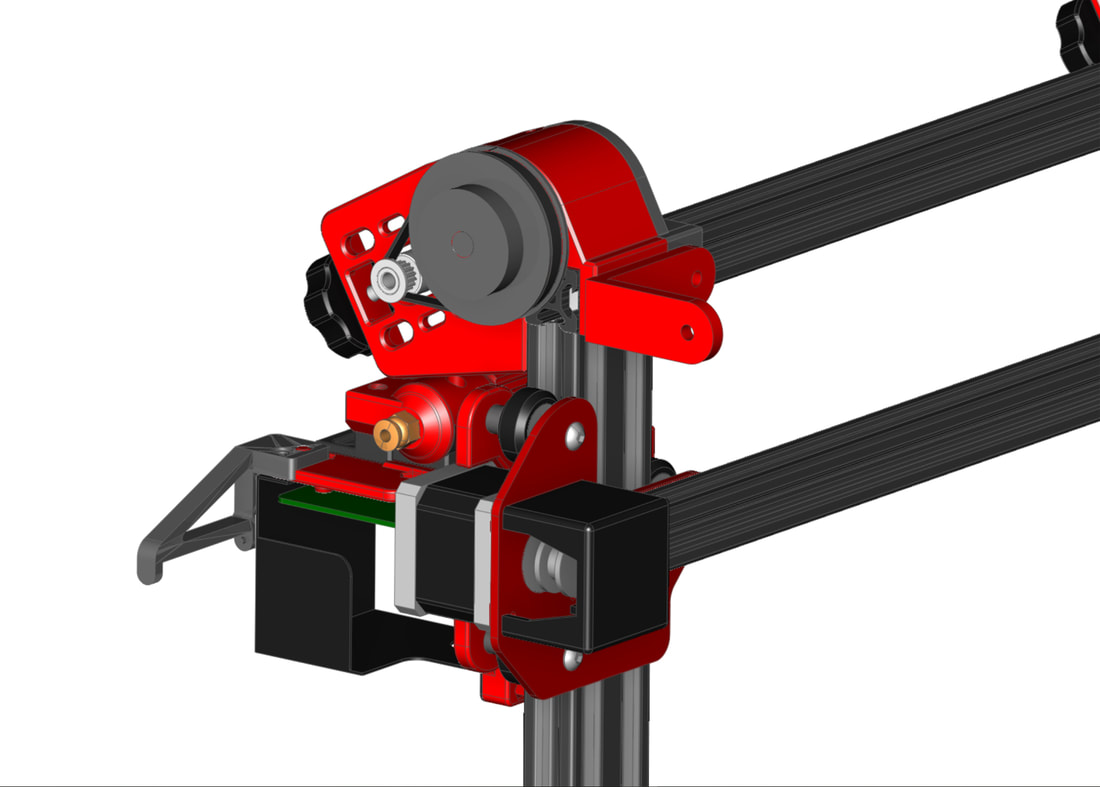

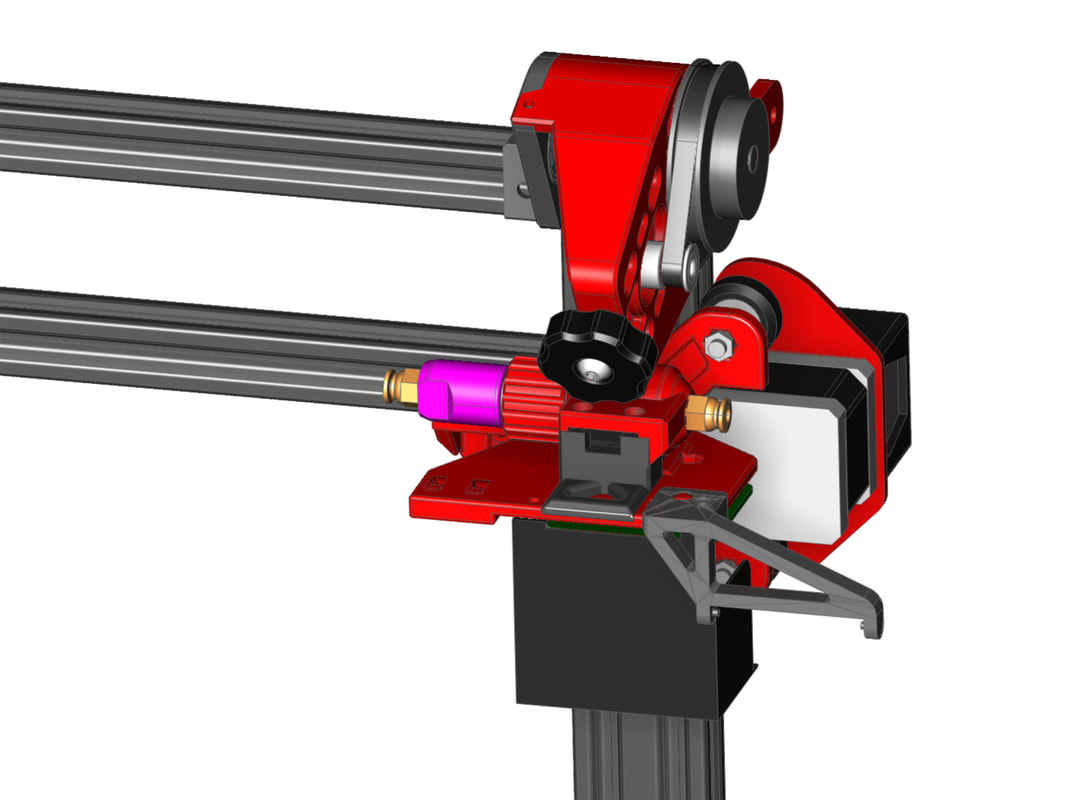

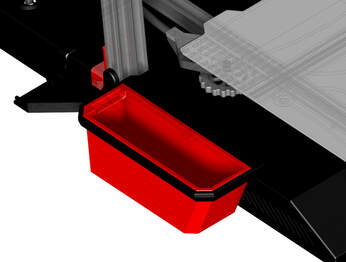

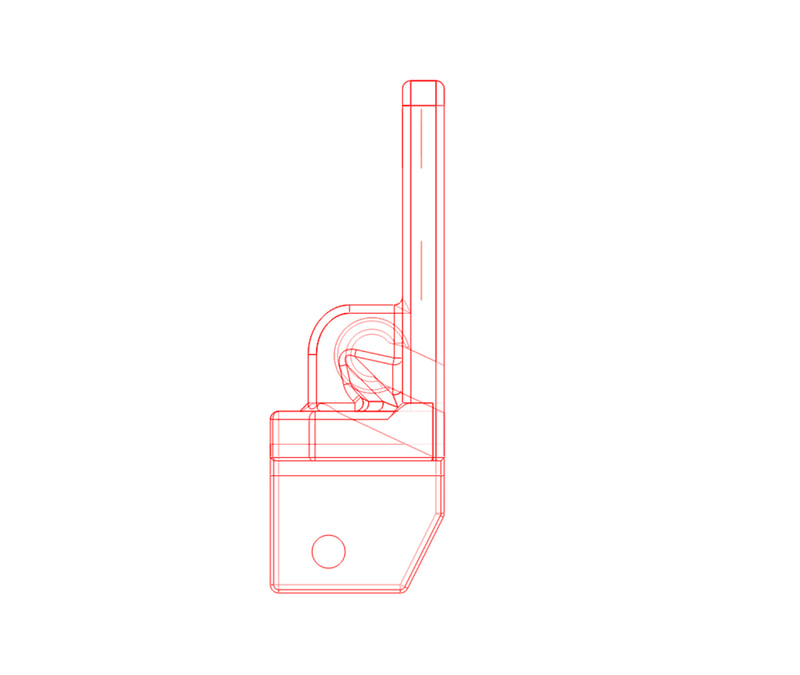

I went a bit overboard though and added a few extra things to the existing models and made some slight changes to help them print with fewer supports. The largest part of the modification though was the left side carriage which required moving the stepper and filament sensor down a bit, in order to accommodate the transmission parts. I should have retained the full 400mm height with this, but I will have to see. I also designed this to still work with my cable chain remix which is unfortunately only for the CR10S Pro V1.

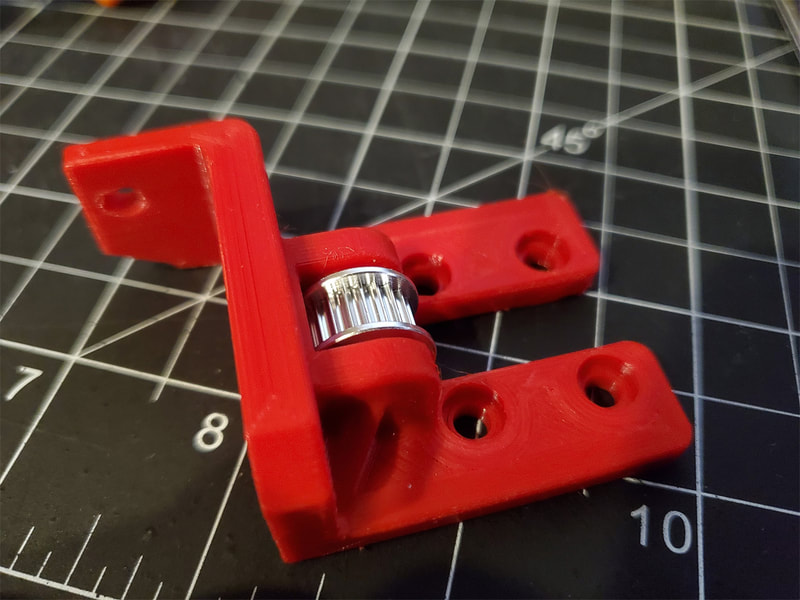

There are a few changes to the transmission housing as well, with it being narrowed down by a bit which will allow me to better use the 65mm rods I will get in the kit, with some aluminum 80 tooth gears (since with the stock design it's a bit tight on the length when using the aluminum gears). I also removed a pocket which was meant for the printed 80 tooth gear and some other minor things. I have printed a few parts already to test things and am really impressed with the fit of Kevinakasam's original design, it's really good and the parts work very well.

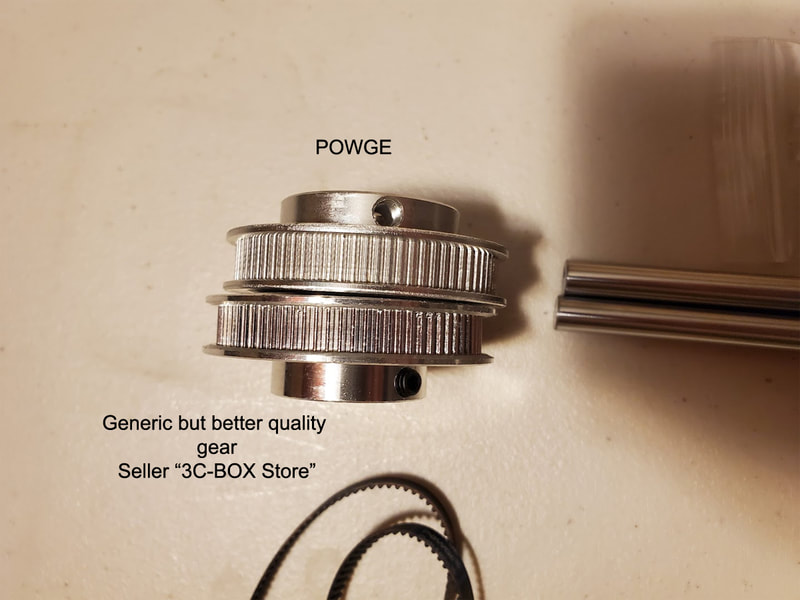

Update 9/14/2022: To their credit, Powge said they would send me some new 8x65mm pins to replace the rusted and pitted pins they sent me with the kit (Edit - communication with the seller was challenging, they asked me to pay a buck to get the replacement rods sent, which I refused, so they said they will ship them but it will be slow :D). I also let them know about the sharp edges on the 80 tooth gears, and told them that I deburred them myself, so I won't be asking for a replacement on that item. I also ordered some M8x65 stainless pins just in case there is a problem. I'm not gonna let the rusty pins stop the build, but will replace them when I get the new ones.

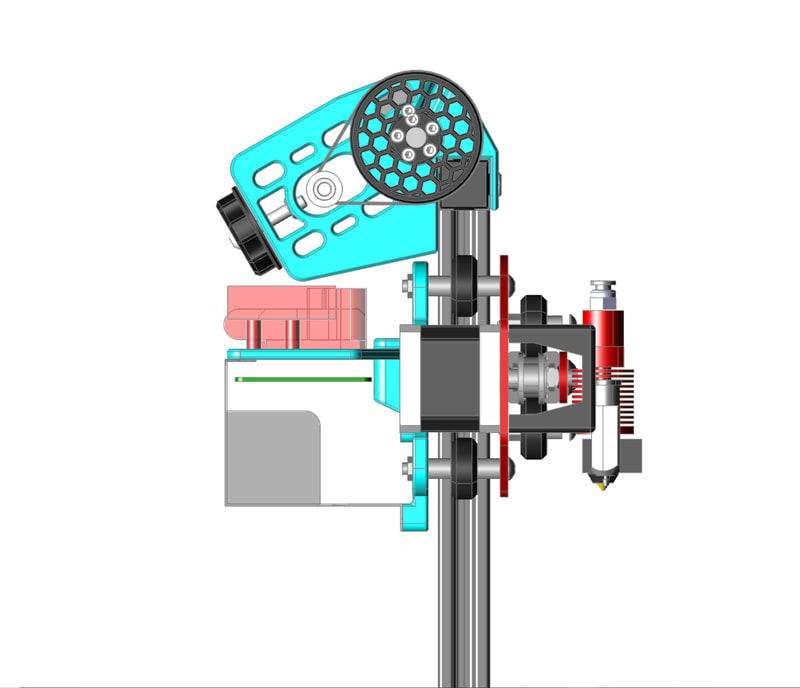

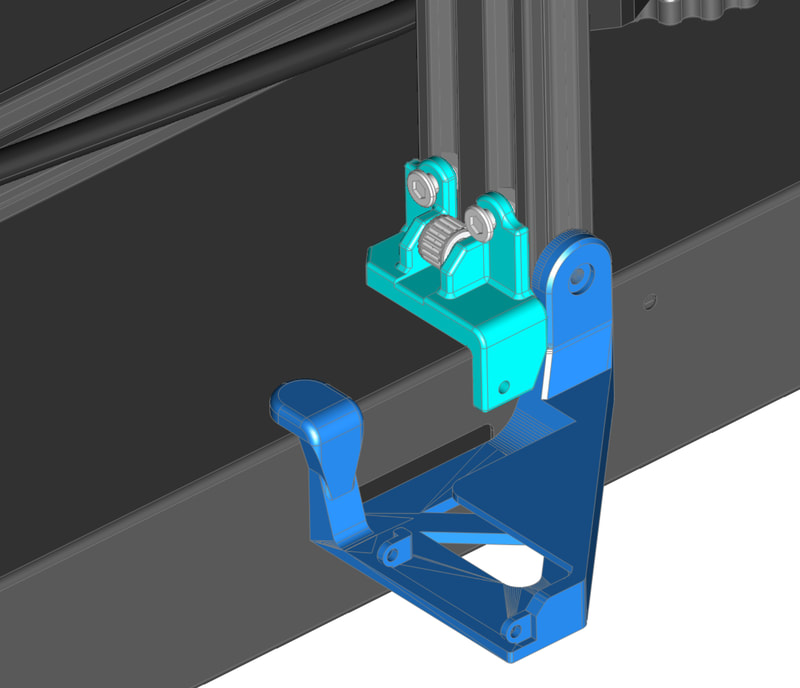

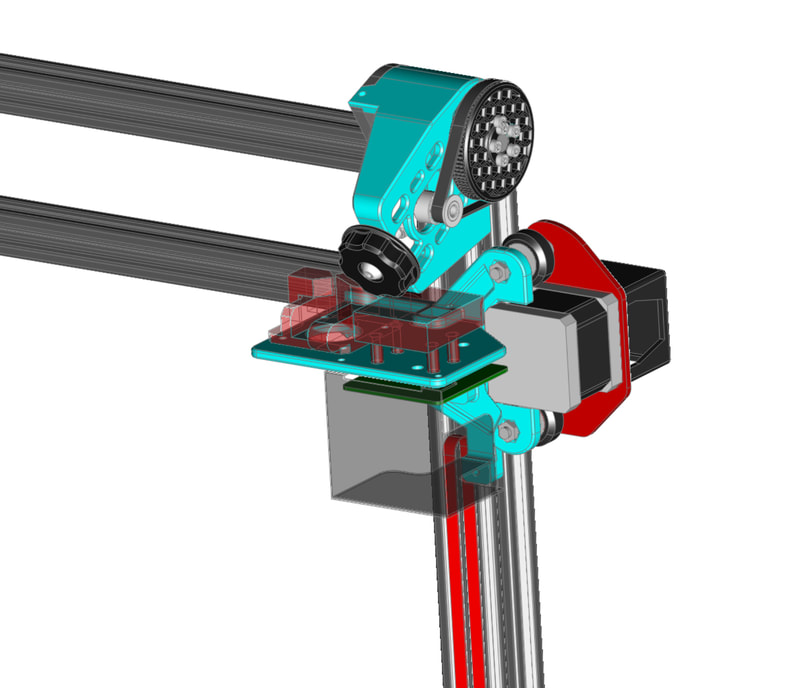

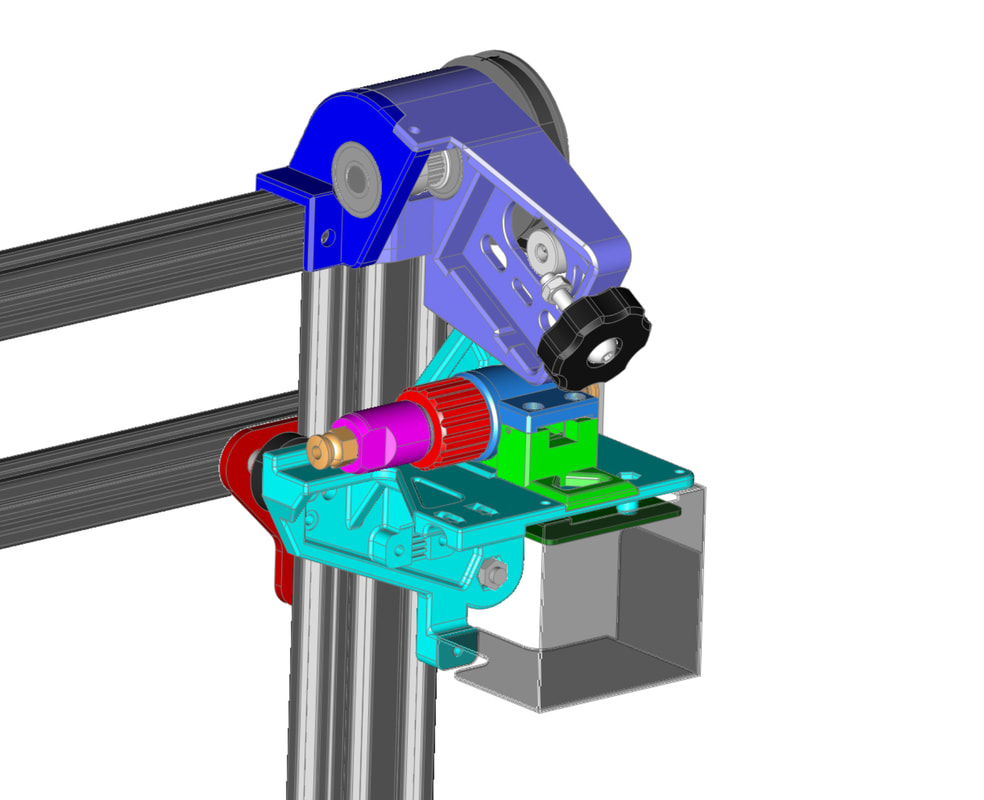

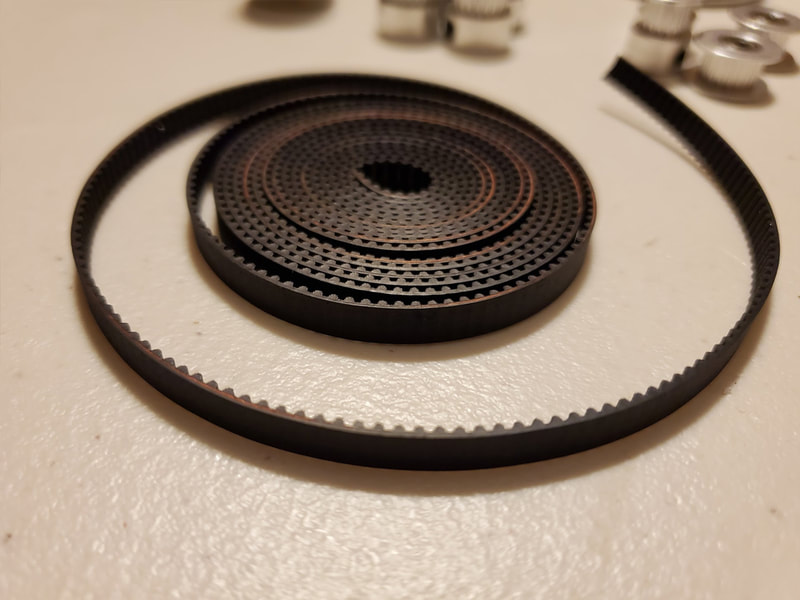

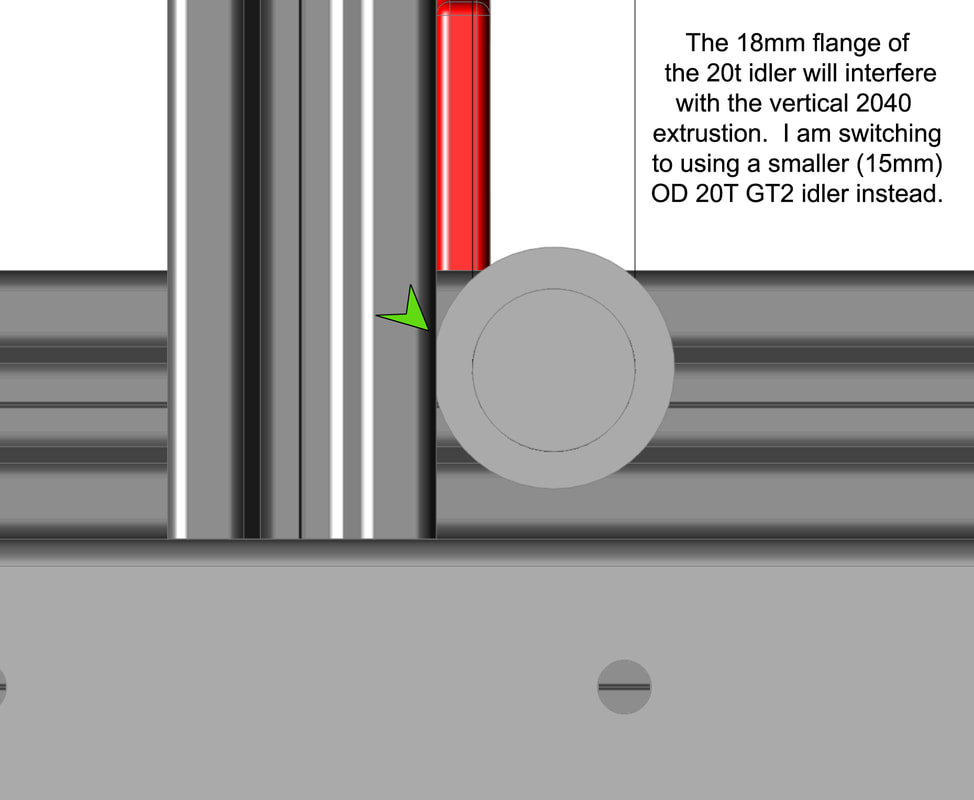

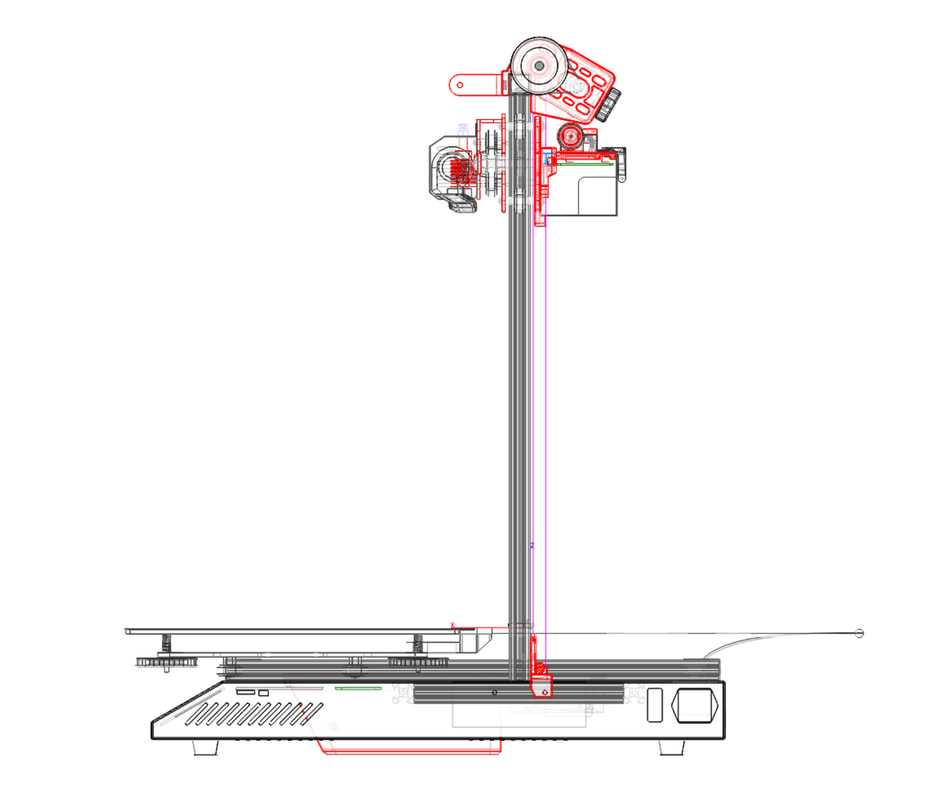

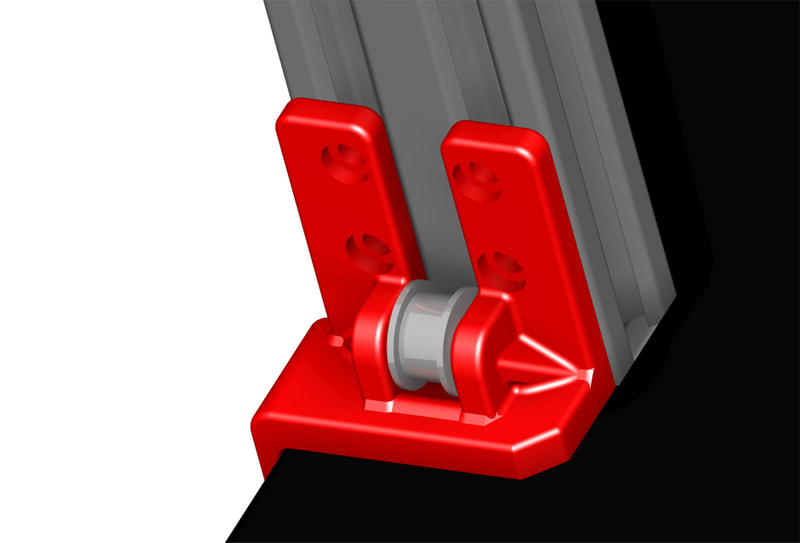

The pic below shows the issue with the GT2 20t idler with an 18mm flange (which I received as part of the kit). I think, though I am not certain why it is, that this problem is only with my modified design. I don't think it affects the original design, but since I was re-working many of the parts, I just went back and set the belts to parallel and made adjustments where needed to make all the parts line up with the belts. The purple/magenta lines in the 2nd pic represent the center of the belts (where the teeth start), and both the up and down runs of the belts are now parallel, which is helped by using a GT2 20t pulley at the top transmission, and an GT2 20t idler at the bottom. The difference in diameter between the GT2 20t idler/pulley (12mm) and the FT623 flange bearings (10mm but effectively 11.5mm) is only about 0.5mm, so it would not have mattered in the grand scheme of things if I went with the FT623, but using the GT2 20t gears just seems like a nicer way to go (at least right in this design phase :D).

Update 10/8/2022: Just a minor note I forgot to mention about the design. I added some spacers to the 8mm shaft to keep everything in place, I added 2x1mm spacers (8x11 1mm) and a 6mm spacer (M8x16 6mm) on the 8mm shaft, which on this remixed transmission, holds the gear in position on the shaft, and keeps anything from moving side to side. The 6mm spacer is not really necessary, as it sits on the side opposite the large gear (between the belt gear and inboard bearing). I could have also just stacked 6x1mm spacers and skipped buying the 6mm spacers altogether. With the spacers installed, it feels like nothing will move side to side.

Update 4/2/2023: Well damn, six months already since the last post, and this project is still on the back burner... Well sort'a. The parts are all printed, but I just have not wanted to tear down my CR10S Pro, which has been a workhorse, to upgrade it with this setup. It will happen, but my primary project is getting my Voron 2.4 built. So this project will be on hold until the Voron is in operation. I'd not mind posting the models to this point as a work in progress if there is any interest. Just know that I cannot test the parts at this time, and would need to have feedback on the design, in exchange for taking the time to post it (as a work in progress). Otherwise it will be posted when I can test it out on my printer.

RSS Feed

RSS Feed