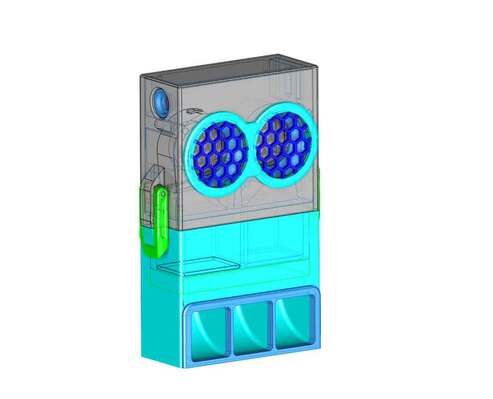

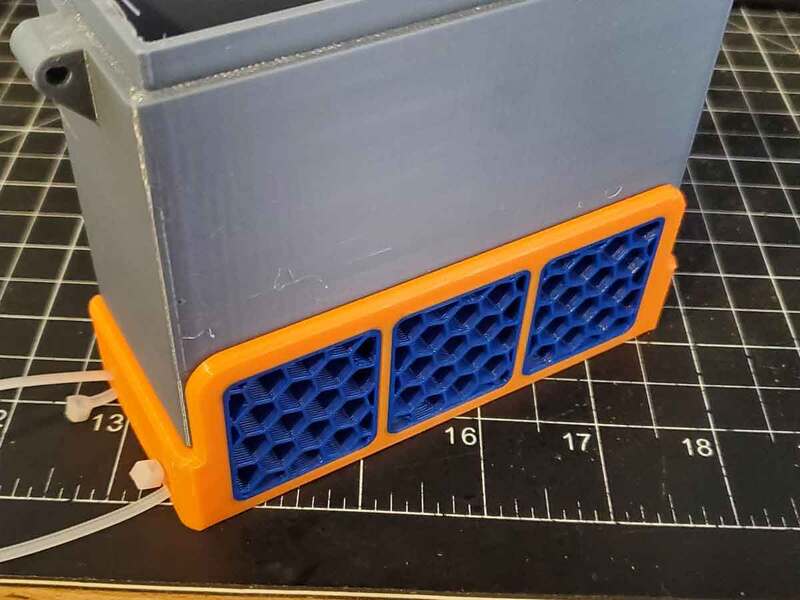

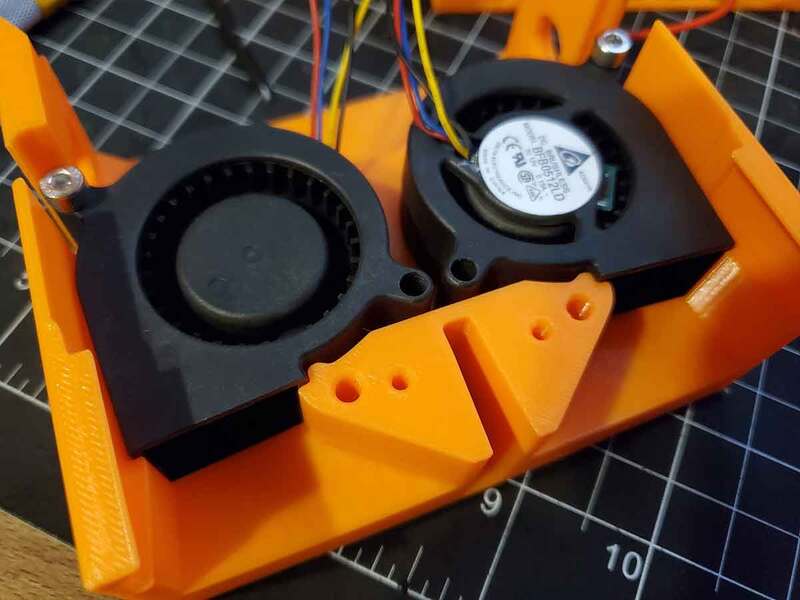

- Bigger fans, specifically 5020 blowers. There is one potential monkey in the wrench though, which is that the fans I bought are GDS Time GDB5020 24V blowers, which are open on both sides. I hope they will work in both orientations, or I will have to re-work this. Update 9/4/2023: I decided to use some 12V PWM (4wire) 5020 blowers instead, since I can easily control the speed.

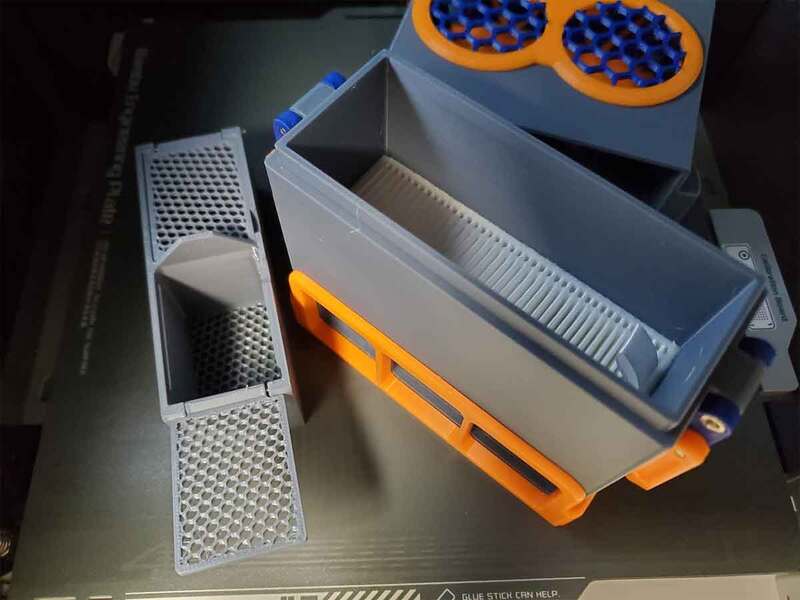

- A bigger HEPA filter. I wanted a larger filter, since it should allow better flow. I already had these on hand from another project (I was working on a nevermore clone, which did not get out of the gate).

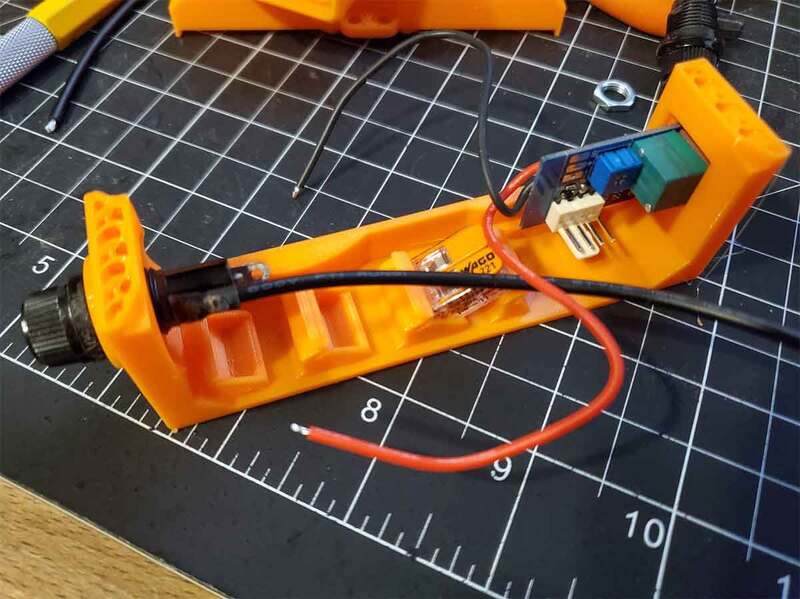

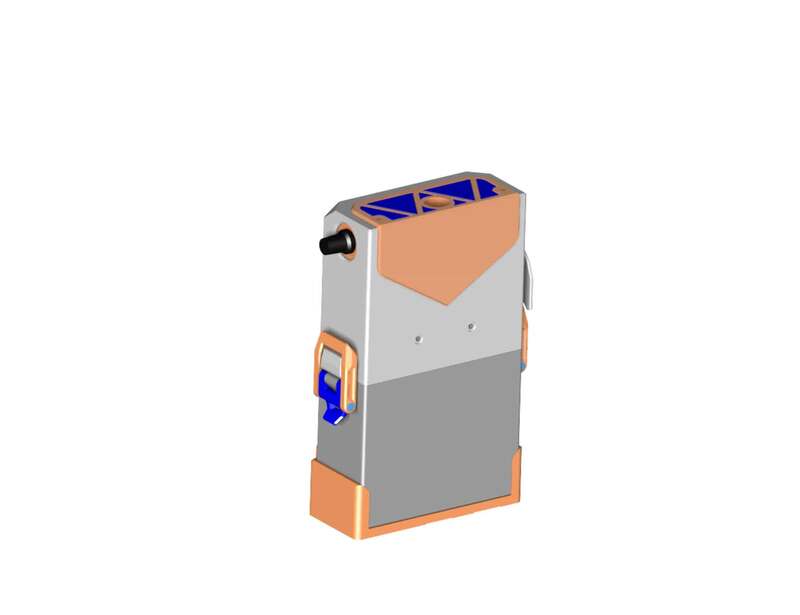

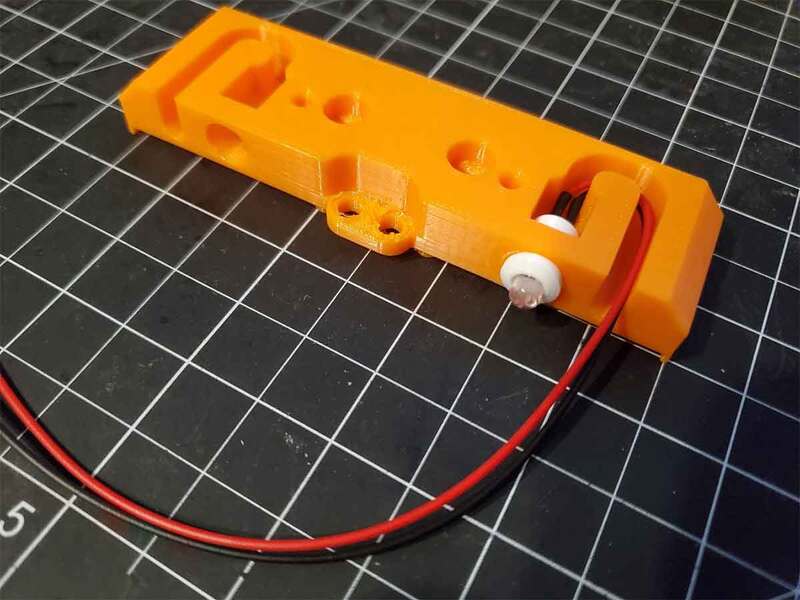

- A switch and DC jack. Most implementations of the Bento Box seem to be hard wired, but I thought it would be more convenient to have a DC jack, so the unit could be removed when swapping the filters. A switch is also handy of course, and there are Bento Box remixes which incorporate one as well.

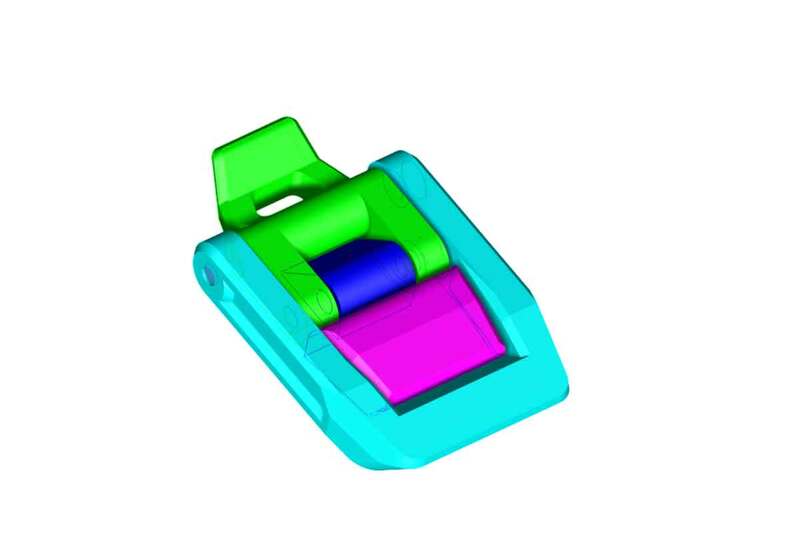

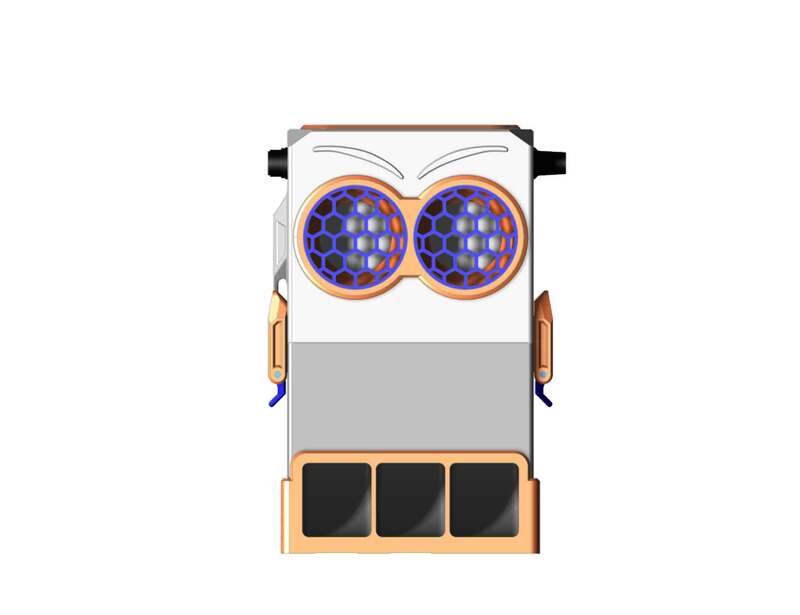

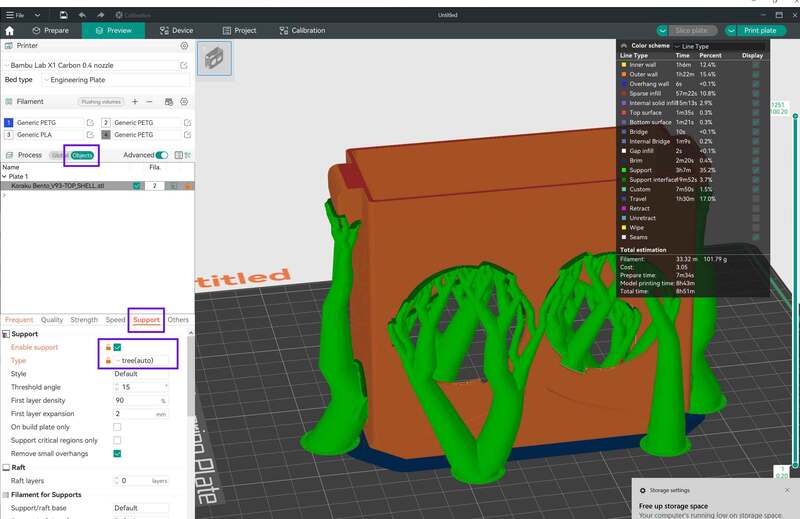

- Fewer compartments, and no magnets. Although I have never seen a Bento Box first hand, the method of keeping the tiers together is through small magnets. I have nothing against magnets for holding lids and things, but I just prefer not to use them as a part of a structure, though the way they are used in the Bento Box does make things convenient. This design uses two compartments, and a pair of draw latches (updated) to hold it together (the latches are a scratch design and are not yet tested).

- A groove to help seal the compartments. Instead of a flush fit between compartments, there is an overlap between them, which should help with keeping the whole thing together and provide some structure. Sealing is less of a concern with a recirculating filter, but it should help with that as well.

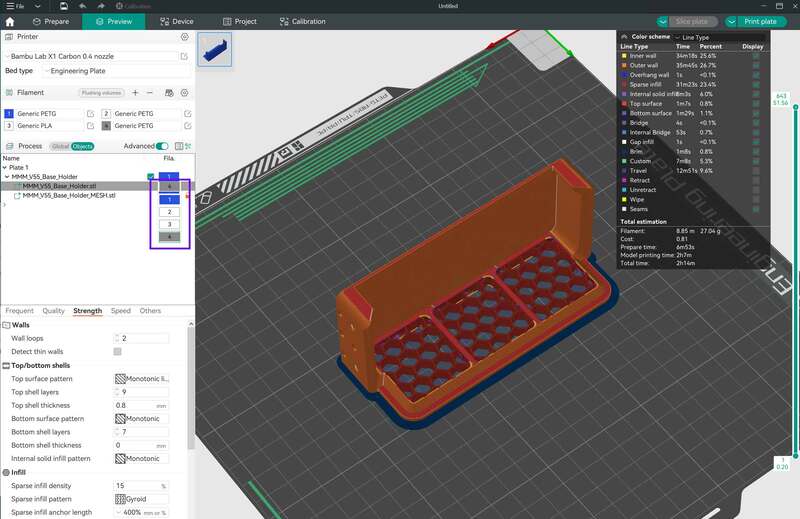

- A removable carbon tray. Some of my other filter designs use a removable carbon filter, and it's handy for keeping the mess down when refilling it. It's not essential, but a preference and since I was going to the trouble I added it.

- Some room for possible additions. The fans and electronic components are housed in a tray, which should make assembly simple, but it also gives some options for upgrading in the future, since there is a bit of extra room. Possibly a temp and humidity sensor with an ESP32, or some sort of smart switch would fit? I'm not planning that currently, but it's cool to have the space.

I'm currently waiting on the fans from China, so I will update with pics as I get it printed and tested.

Update 9/2/2023: I decided to use a normal draw latch design, which will use M3x20 and M3x30 mm screws. The latch is untested, like this whole thing, so it will be a while before there is another update.

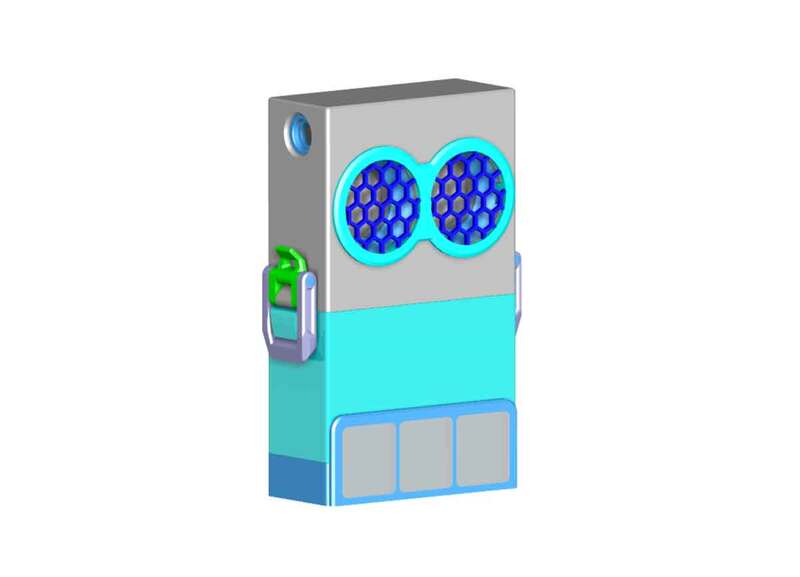

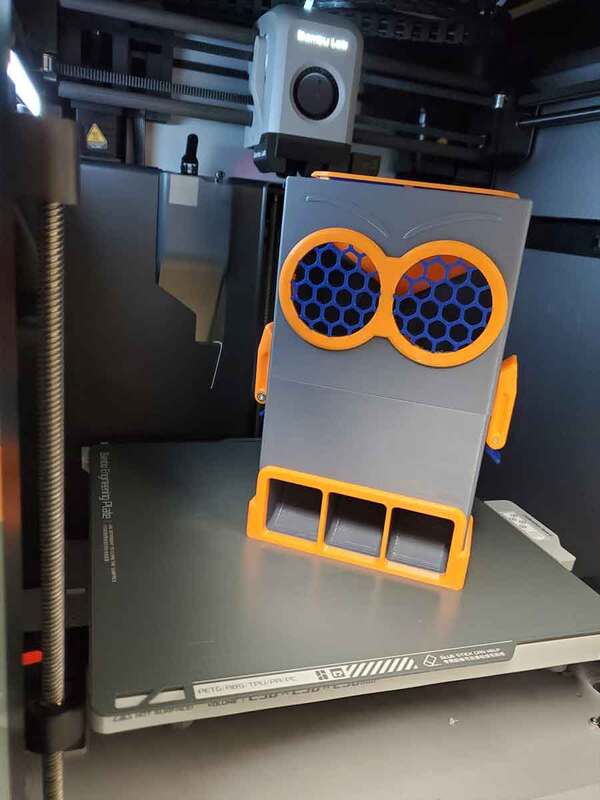

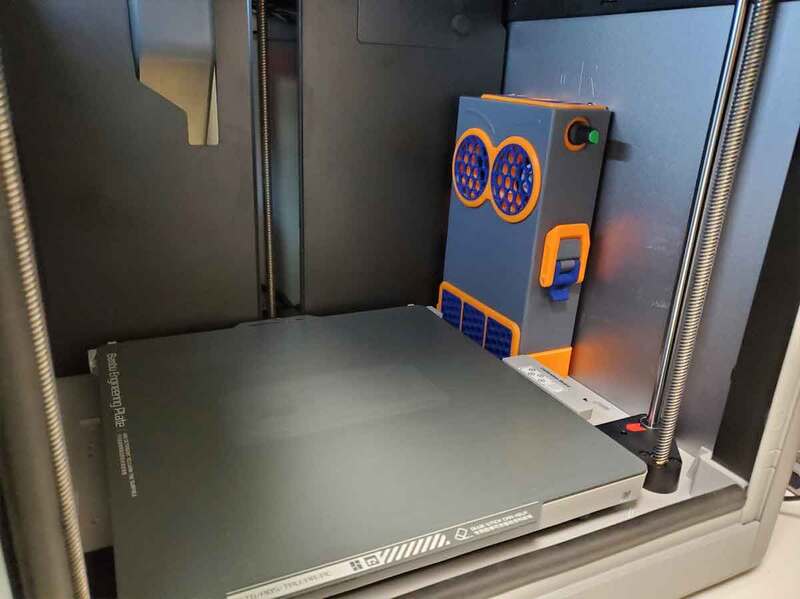

Update 9/3/2023: Just one more quick update. After seeing the way the design has a "face", I'm thinking of naming it "Marvin the MircoParticle Machine".

I'm also really liking the latches, and already have some ideas to use the same draw latch design in some other projects.

I found that the pre-wired fuseholders I ordered are poorly assembled, so it's almost impossible to remove the nut that is used to secure them. I also broke one of the poorly soldered wires off one of the holders, and another shattered when I was trying to remove the nut (which was my fault, but still sucks). So I'd not get the pre-wired fuse holders again, and instead would get the type that require soldering some wires to. However, I was able to get my pre-wired fuseholders to work (after finally removing the nut), and also threaded the hole they will go into (with an M12x1mm thread). I also made an allowance for the wires to pass through, in case the pre-wired holders are used. It's a lot of work for a fuseholder, but I think it's worthwhile for something they will be running for hours.

Although everything was just temporarily connected together for testing, I was surprised how powerful the fans are. I did not have the carbon container filled up, but even just blowing through the HEPA filter, they move air pretty well. I think having the ability to fine tune the airflow using the speed controller is going to be very useful too. I would not call the fans quiet, though they are not too loud either, and having the ability to turn down the speed, also turns down the noise. Overall I am really pleased with the performance so far.

I'm running some further full function parts now, and if all goes well, I hope to have the model built this week, so I can run it for some longer tests in the X1C.

There will be some extras in the revised design, but I may release it without the extras if the parts don't arrive soon (they will be an easy upgrade though). I'm probably just gonna print and test enough of the revised design to verify there are no interference issues, since otherwise I'd need to tear apart my perfectly good filter to scavenge the fans (since I have another pair of those "4 wire" fans on order). The revised design has only a few changes which are mostly under the surface, so what works in the previous design which I printed, will work in the updated one as well.

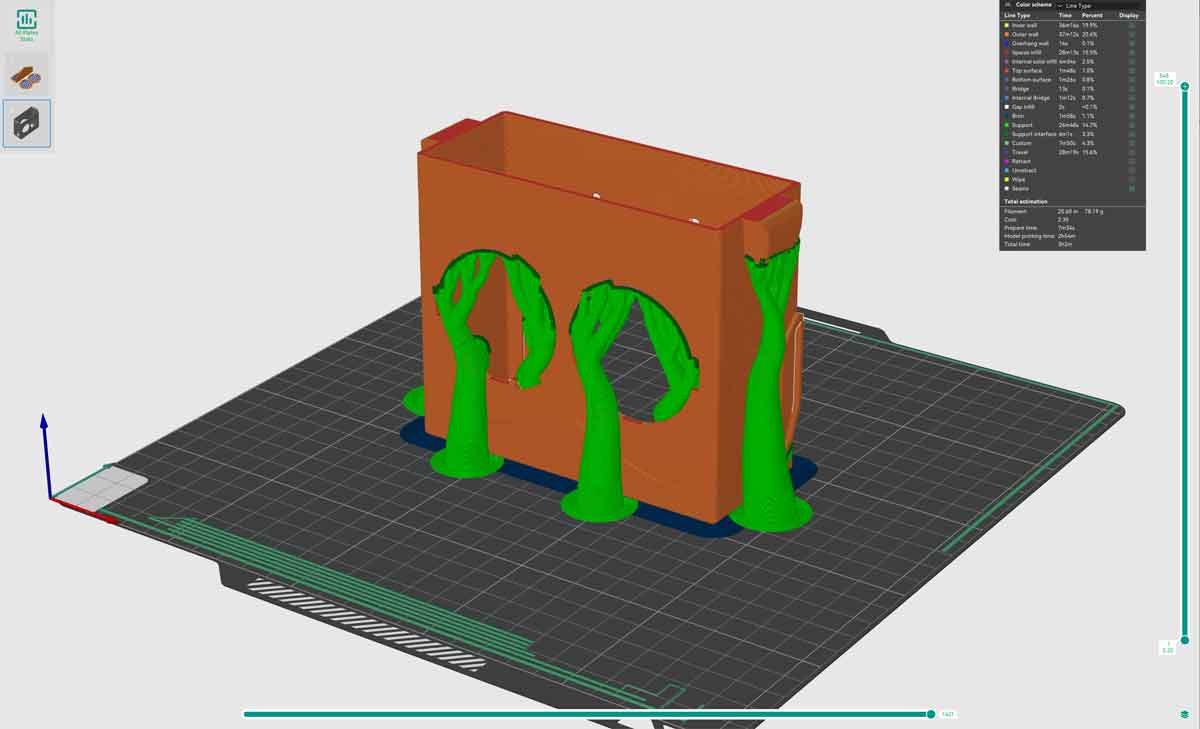

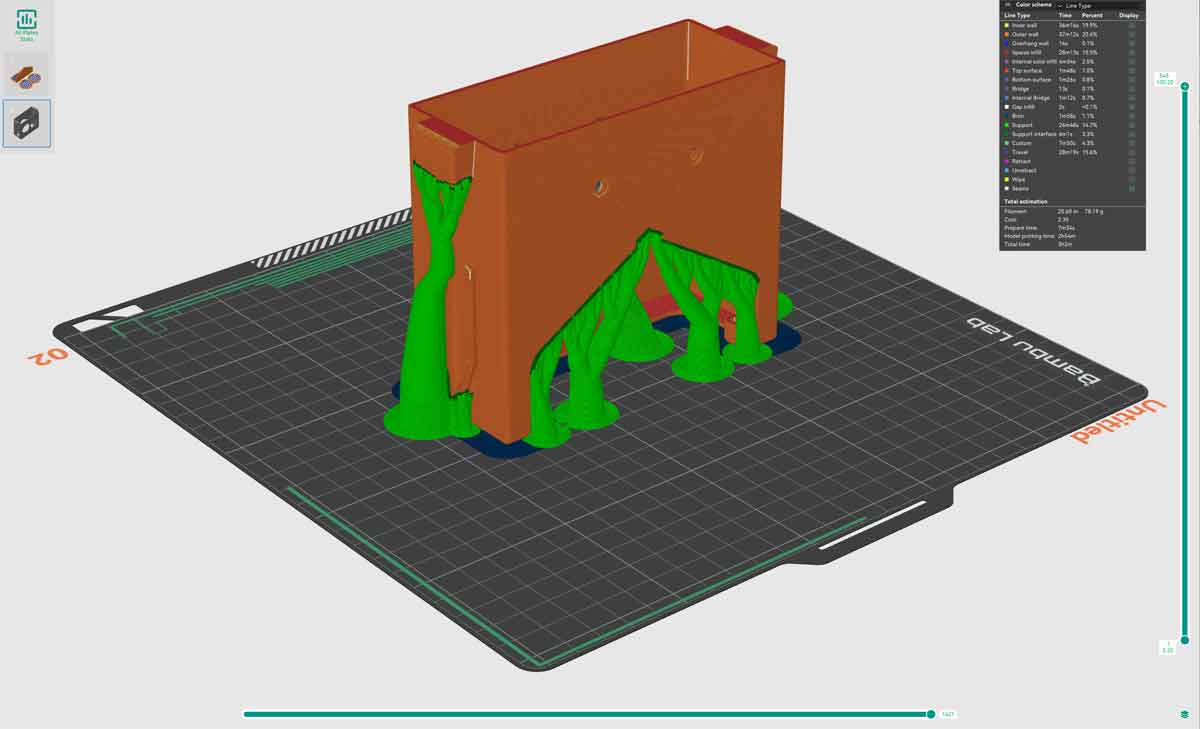

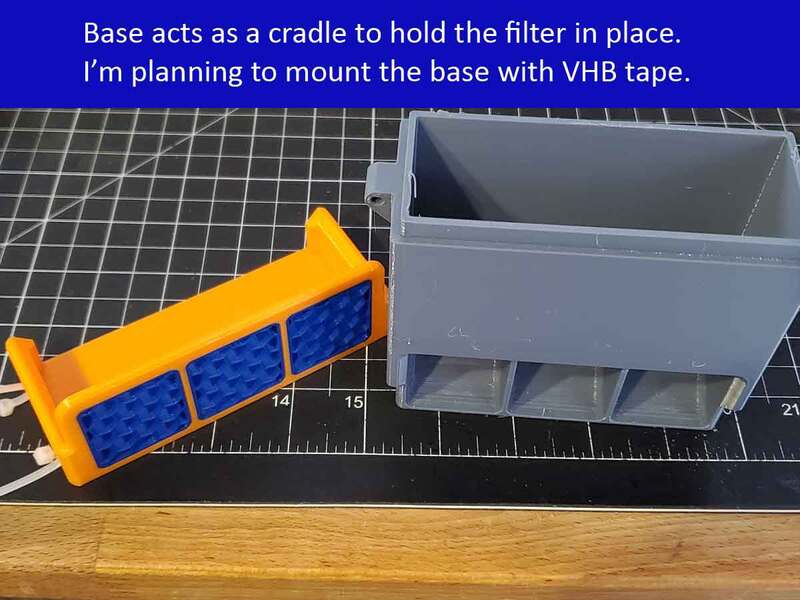

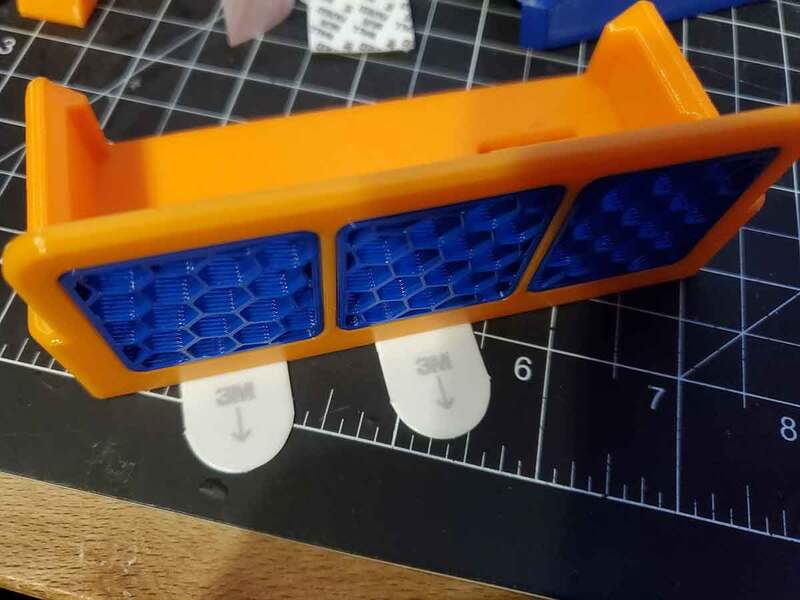

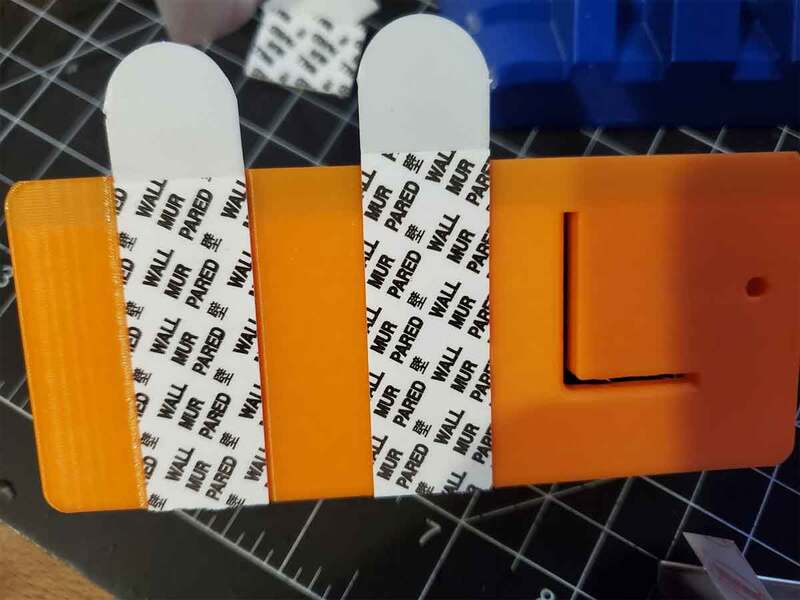

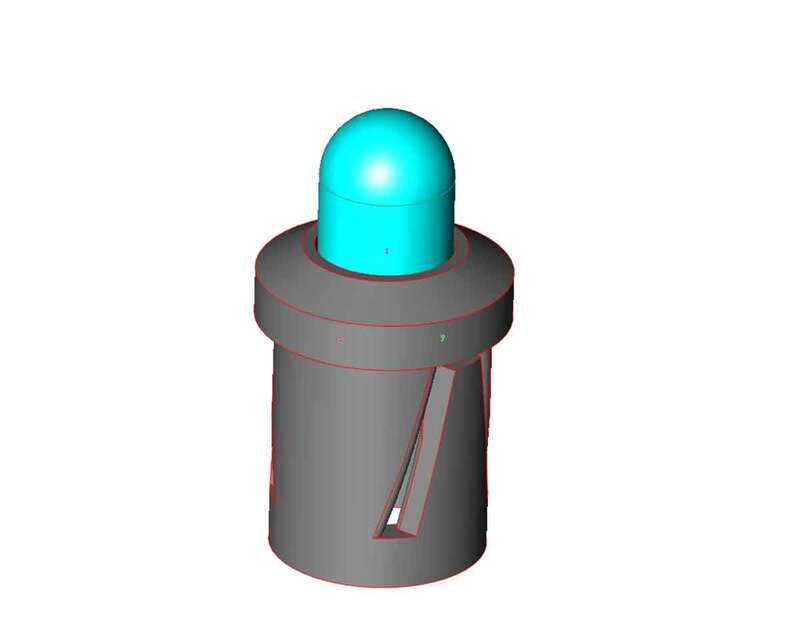

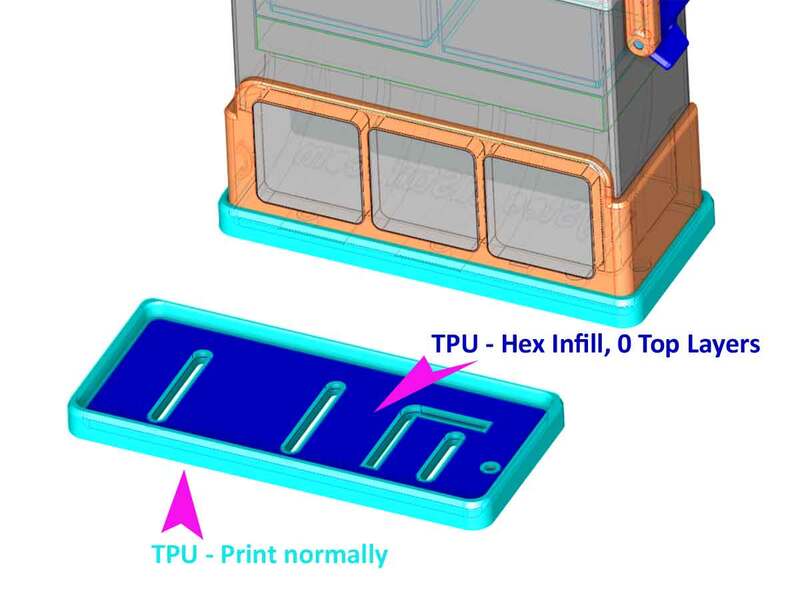

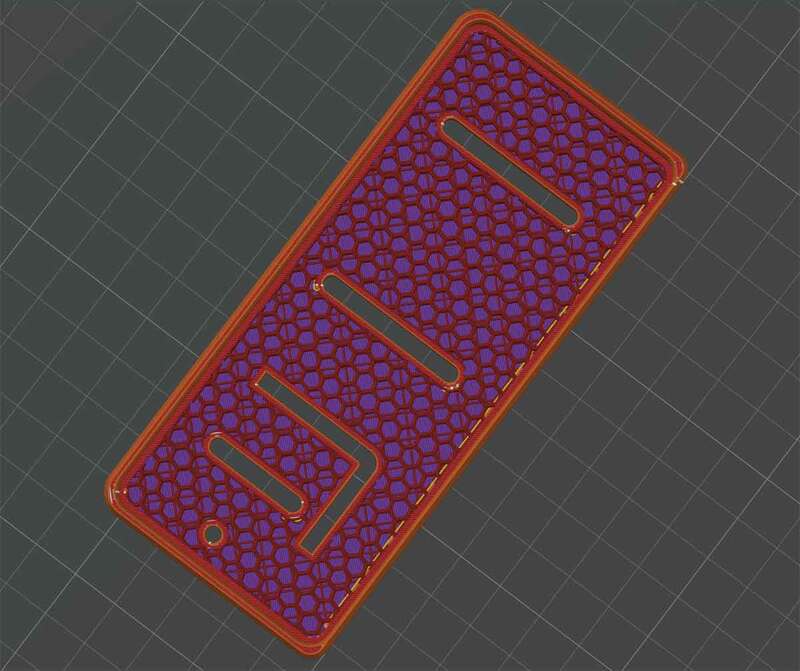

Update 10/23/2023: A simple TPU base may help reduce the fan vibrations, at least that's the hope. The pics show a pad design that the "cradle" sits on. The pad is going to be printed in TPU, with the dark blue area being printed as infill only (no top or bottom layers). That should produce a vibration reducing base for the filter to sit on, with enough support if the infill density is high enough. I'm thinking 20% Hexagonal infill will work (see pics). I will need to dry some TPU and test this, which should be possible to do later this week.

RSS Feed

RSS Feed